It is known that the picturesque man-made dacha pond is the pride of the owner, behind which there is a complex process of creating a pond. Starting from the primitive waterproofing with the use of natural clay, waterproofing materials, like a membrane HDPE, acquire new qualities.

Content

Flexible waterproofing, in the form of a traditional film, has long since grown from short panties. Today it is a material representing a powerful alliance of high chemical technologies. However, the basic technology of waterproofing has practically not changed. Only the methods of applying the material have changed.

Technology of waterproofing of reservoirs

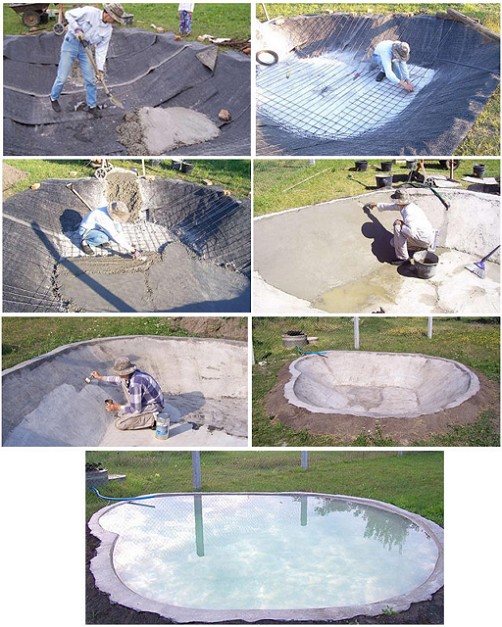

The technology of waterproofing artificial ponds and ponds is as follows:

- preparatory works for excavation of foundation pit by manual or mechanized method

- leveling and ramming the walls and bottom of the excavation

- laying waterproofing material (film, geomembrane) or application (liquid rubber)

- strengthening the upper edge of the film walls of the pond (welding)

- processing of technological seams and strengthening of terraces

- preparation for filling the pond bowl.

Recall that non-compliance with the technological cycle of waterproofing or the appearance of a defect can adversely affect the quality of the waterproofing layer. Therefore, the choice of the type of protective material is particularly relevant.

Materials for the waterproofing of reservoirs

The main stage in creating a man-made pond is its waterproofing. The choice of waterproofing material and the creation of a coating must be approached reasonably, the type of waterproofing must be strong and elastic, capable of withstanding the pressure of water pressure.

It is necessary to distinguish between flexible and rigid waterproofing.

There are several types of waterproofing, which characterize the mechanical and physical properties:

- waterproofing with liquid rubber

- use of a film

- concreting

- geomembrane.

Choose the type of coverage is necessary from the parameters of the relief of the sites of the pond and the depth of the pond.

waterproofing flexible

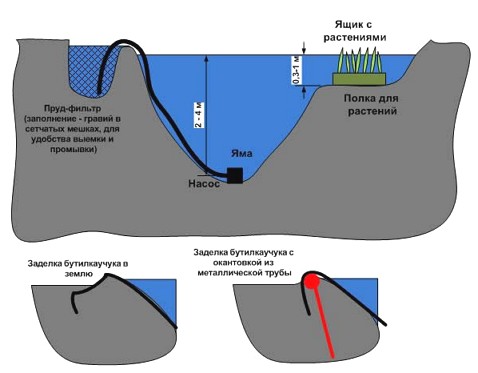

To flexible waterproofing, which is preferable to use for rocky terrain, include film materials and butyl rubber. The thickness of the film is selected in accordance with the depth of the pond. For example, for a pond with a depth of 1.5-1.7 m, the thickness of the waterproofing film is selected to be 1.5 mm. For a shallower depth, it is more practical to use a flexible waterproofing of 0.8 mm.

Helpful Tips

When carrying out the waterproofing of the reservoir with a film, a preliminary calculation of the volume of the material is carried out. The width of the film is chosen to be equal to the width of the pond plus a double depth (for placement on the walls) and plus an additional 1 m in addition. The length of the required film is calculated from the calculation of the length of the reservoir and plus the double depth. The film is manually laid on the bottom and terraces, reinforcing the edges with stones. The final stage is the decoration of the edge line of the pond.

clay waterproofing

The most simple and relatively cheap type of waterproofing is considered clay waterproofing, produced manually using natural material by applying two layers. An indispensable condition contributing to good waterproofing is the light and ductile consistency of the clay.

rigid waterproofing

Hard waterproofing in the form of ready-made tanks with terraces is used to create a dense shoreline and cover the bottom. Finished waterproofing in the form of a fiberglass bath (bath) is easy to install and provides a gentle installation mode in order to make a pond.

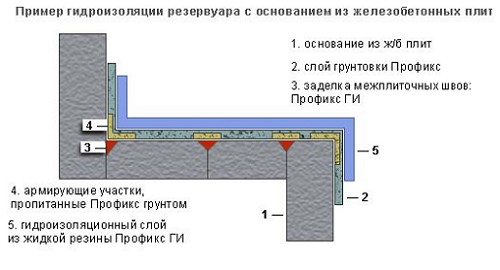

pond concreting

In the case where concrete is planned to be pitbed and as a protective layer concrete will act as a waterproofing, the set of materials and equipment will increase, as, indeed, the cost of work. For concrete waterproofing you will need:

fine cement, fine gravel, coarse sand, formwork boards and equipment for the preparation of mortar for pouring.

An alternative to increasing the cost of waterproofing works to protect the reservoir is a film.

Helpful Tips

Price comparison of waterproofing materials, makes it clear that the most expensive option for creating a protective coating is geomembrane and ethylene-propylene rubber. The cost of film waterproofing is low, the benefit of film material in the form of PVC, HDPE or PEVD is easy to install and is in demand when creating not only artificial reservoirs.

Let's say that the technical characteristics of PVC film are:

- high stretching - 200%

- strength (static load) up to 20 kg / m at a pressure of 2 kPa.

However, the distinctive characteristics of butyl rubber used in waterproofing a pond with a film are:

- stretching 300-450%

- 100% stability of the web size under tension and elongation

- ozone and ultraviolet resistance according to euro standards ASTM G 53-84 and DIN 7864 and the possibility of contact with drinking ANSI / NSF-61 water.

Among developers, the waterproofing of the pond with a film is considered the most in demand.

waterproofing with liquid rubber

The technology of liquid pond waterproofing is considered progressive and innovative. The technology consists in laying the geomembrane of geotextile bonded on the prepared soil of the foundation pit and fixing it along the upper edge.

As an excellent insulating material, a two-component aqueous polymer-bitumen emulsion capable of withstanding t = 60 ° C is used.

Subsequent spraying of liquid rubber and its gradual absorption into the geotextile substrate provide a monolithic and, notice, seamless surface that does not allow leaks.

It remains to paint the waterproofing layer by spraying a special enamel for painting.

How to produce a waterproofing pond by spraying liquid rubber, shown in the video.

geomembrane

The correct choice of waterproofing material is the geomembrane HDPE, which allows you to build a pond or pond in any soil, regardless of the particle size distribution.

Let us suggest that the strength of the geomembrane provides a higher density of material, high water resistance ensures high-quality processing of LDPE and HDPE weld seams.

In practice, the use of a geomembrane is considered economically viable.

For example, a membrane roll EPDM PondLiner, black, 1.02 mm thick, measuring: 3.05 m х 30.48 m will provide coverage of the reservoir with an area of 92.964 m2.

But all the above methods of waterproofing the pond gradually give way to more technological methods, such as spraying polyurea.

To create a monolithic layer of the pond bowl, two layers are applied: the first spraying of polyurethane foam (PPU) and the second one - the spraying of polyurea in gray color.

More information is available here.

![oformlenie-vodoema-8 [1] _900](http://svouimirukami.ru/wp-content/uploads/2017/04/oformlenie-vodoema-81_900.jpg)