During the construction of buildings of any type, one of the most important issues is the waterproofing of such structural elements as the foundation, roof, floors, walls, etc. Moisture has a negative impact on building materials such as concrete and brick, expands the micropores, which leads to the appearance of cracks, and as a consequence, premature aging and destruction of structures. One of the simplest and most affordable ways to create a waterproof layer is a coating of waterproofing. This type of protective material is widely used for both internal and external works. The coating waterproofing material is a sealed multi-layer coating having a thickness of several millimeters to 2-3 centimeters.

Content

- 1 Types of lubricating waterproofing: bitumen-based insulation

- 2 Bitumen-polymer coating waterproofing materials

- 3 Bitumen-polymer emulsions

- 4 Latex coating waterproofing

- 5 Cement-polymer coating waterproofing materials

- 6 Damp-proof waterproofing tehnonikol

- 7 Preparatory work before application of coating waterproofing

- 8 Waterproofing the bathroom with self-lubricating materials

Types of lubricating waterproofing: bitumen-based insulation

Bitumen coating waterproofing refers to the traditional protective material, which have a fairly high efficiency.

Benefits of bitumen mastic:

- High degree of protection against moisture.

- Mastic is elastic, easy to work, it can be applied at negative temperatures.

- Low cost.

The disadvantages of waterproofing materials based on bitumen include:

- Short-lived - the service life of the material is a maximum of 5-6 years.

- Poor resistance to negative temperatures - even at 0 C, such a coating begins to crack and peel off.

- Fire hazard - waterproofing works are carried out at a fairly high temperature of the material, which can lead to its ignition.

Bitumen-polymer coating waterproofing materials

In order to improve the characteristics of waterproofing materials based on bitumen, they add latex and polymers. Adding these components allows you to:

- It is essential to increase the elasticity of the material.

- Improve the adhesion of the mastic and the substrate on which it is applied.

- Expand the temperature range.

Bitumen-polymer mastics of various grades can be applied to the surface by heating or cold. So, if the developer does not want to deal with hot material, he can buy a bitumen-polymer insulator that preserves the liquid consistency due to the addition of organic solvents. Mastics based on bitumen, containing organic solvents, are recommended for outdoor work, as well as for rooms with forced ventilation. They are used, as a rule, for processing relatively small surfaces.

An example of such material is the slurry waterproofing slavyanka - fully ready-to-use single-component bitumen-polymer composition.

Mastic "Slavyanka" is a homogeneous mass of black in consistence similar to paste. This material is used for processing concrete concrete, and metal structures. "Slavyanka" can also be used to handle rooms with constantly high humidity - bathrooms, rooms, bathrooms, laundries, etc. This material is not intended for use in a residential environment. Waterproofing works should be carried out away from sources of open fire. With mastic Slavyanka work in the open air or in well-ventilated rooms.

Bitumen-polymer emulsions

Waterproofing in rooms, in particular, basement, it is expedient to carry out using bitumen-polymer compositions on a water basis. The use of waterproofing materials of this type at positive temperatures guarantees high resistance of the treated surface to moisture, and the quality of the emulsion is in no way inferior to the mastics of hot application. Bitumen-polymer emulsions freeze quite quickly, which allows processing large areas in a relatively short time.

Latex coating waterproofing

This waterproofing material is also called liquid rubber. When applying latex mastic used specialized equipment, due to which the productivity of the work can reach 1000 square meters. m. per day. An example is the rubber-bitumen emulsion Knauf-Flahendicht.

The material does not have a solvent in its composition, it has good adhesion with cement, concrete, gypsum, lime, drywall sheets. Emulsion is environmentally friendly, completely harmless to health, odorless and tasteless. The material has received numerous positive feedback from consumers.

Fields of application of the Knauf-Flahendicht emulsion:

- Places of possible moisture penetration, before the installation of the facing material.

- Foundations.

- Basement rooms.

- Processing terraces, roofs, balconies.

- Waterproofing of swimming pools.

- Processing of metal structures.

Emulsion is widely used for both internal and external works.

Cement-polymer coating waterproofing materials

The composition of this waterproofing agent includes cement and plasticizer additives. So, waterproofing Bergauf Hydrostop contains in its composition cement as a base with the addition of fillers, quartz sand, polymeric and hydrophobic additives. Mastic is used for processing pools up to five meters deep, cellars, socles and facades. This material can be used for internal and external treatment of premises with high humidity.

Damp-proof waterproofing tehnonikol

The assortment of lubricating waterproofing materials of this brand is wide enough, it includes materials for different purposes:

Inexpensive bituminous mastics of hot application. The most affordable materials, but require warm-up for work. To such it is possible to carry mastics of series MBK-G, which belong to waterproofing materials of class "economy". They are usually used for external processing of various elements of building structures under any climatic conditions.

Before starting the work, the mastic is heated with constant stirring to a temperature of 160-180 ° C. The treated base is cleaned of dust, covered with a primer layer. Waterproofing lateral coating is applied by roller or brush. If a horizontal surface is treated, the mastic is poured and leveled with scrapers. As a result, a solid, strong protective layer is formed, securely adhered to the base.

Bitumen-polymer mastic "Technonikol-№41"

It is designed for roof waterproofing, has such an important advantage as a very high rate of solidification. This material is used in the construction and repair of roofs, the processing of metal structures, concrete blocks and columns, whose base is in the ground. The material is made on the basis of bitumen with polymer additives, and mineral materials. Apply by brush or roller.

Mastic cold application "Technomast" is a completely ready-to-use waterproofing material. The basis of the mastic is bitumen, modified with artificial rubber, as well as mineral additives and organic solvent. Mastic is applied to the surface with a spatula, brush or in bulk. Areas of application - processing of foundations, columns, piles, and other structures buried in the ground, and in direct contact with moisture. It is also applied to metal pipes and car bodies in order to prevent corrosion. The thickness of one layer does not exceed 1-1.5 mm. Each subsequent layer of mastic is applied only after the previous one has dried completely. To obtain a guaranteed result, apply at least two layers.

Mastic water-based Tehnonikol No. 33 is produced by grinding the latex-modified bitumen in an aqueous solution of the emulsifier.

Mastic is used for the processing of foundations, piles and columns buried in the ground. The material can be used for waterproofing bathrooms, cellars, pool floors, terraces and balconies.

Preparatory work before application of coating waterproofing

In order to form a high-quality protective layer, it is necessary to thoroughly prepare the surface.

For this you need:

- Eliminate areas affected by corrosion, stains of dirt or oil with a brush, scraper or other means.

- Clean the surface of the dust.

- Cracks and grooves should be cemented with cement mortar.

- Cut the protruding reinforcement, bring down the flow of mortar or concrete.

- Treat the surface with a deep penetration primer. To do this, you can use a waterproofing material, diluted to a more liquid consistency.

Waterproofing the bathroom with self-lubricating materials

The bathroom is a room with constantly high humidity. In addition, while the process of taking water procedures, there is a constant flow of water onto the floor and spraying onto the walls and ceiling. In the absence of a quality waterproofing layer, this eventually will inevitably lead to the flooding of neighbors from below and damage to your housing.

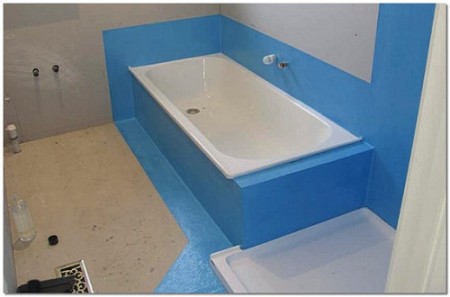

Below we will consider the process of waterproofing the bathroom with coatings.

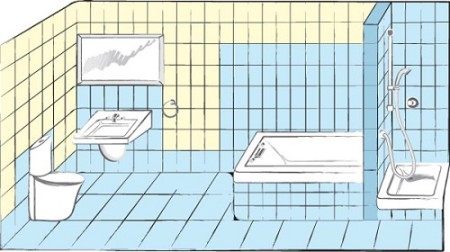

It is necessary to start with an exact definition of the so-called "wet zones" in the room.

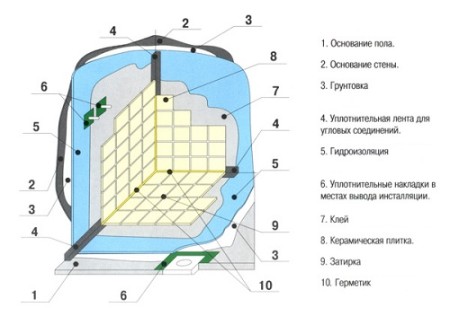

These can be parts of walls and floor that are exposed to direct water. Typically, such places are the walls and areas of the floor, adjacent to the shower, bath and washbasin. Walls are recommended to be treated with one or two-component liquid waterproofing mastic, which includes cement, sand, plasticizers and polymers.

Polymer additives bind together sand particles, resulting in a completely waterproof coating. Cement, in turn, turns such a coating into a monolithic, with high strength. Plasticizers prevent cracking of the waterproofing coating.

Before the beginning of the works, we free the walls from the old covering - tiles or paints. To do this, you can use a spatula puncher.

Waterproofing coating for the bathroom can be a one-component mixture or a two-component composition. Their characteristics are almost identical, the difference is in the application technology. The one-component mixture is diluted with tap water in the correct proportion. The resulting mixture is applied to the surface of the wall with a brush in several layers. The mixture must be applied only on a wet surface, so that the solution freely penetrates into the pores of the base. The layers are applied at intervals of 4-6 hours. The thickness of each layer is from 2 to 3 mm.

The two-component mixture is diluted not with water, but with a special polymer emulsion. Such waterproofing material reliably protects the walls of the bathroom from the appearance of fungi and mold. After the work with the walls is over, you can proceed to the floor. We remove the old coating and clean the base of dust and debris. After that, we carefully examine the places where the floor joins the walls - there are no cracks and chips. In case of their detection, it is necessary to expand the chipped or cracked chisel to a depth of about half a centimeter. Next, carefully fill the gap with a strong cement mortar and carefully smooth it. When the solution completely solidifies, we ground the entire surface of the floor and adjacent walls (to a height of 10-15 cm) with a primer of deep penetration. This will help bind the surface layer and improve adhesion.

The floor waterproofing is made with mastics intended for waterproofing of bathrooms and bathrooms on bitumen base, or mastic containing polymer components.

For bituminous mastics there are several restrictions in the application. So, bitumen waterproofing for the floor must be diluted with a solvent or gasoline. These are toxic and fire hazardous materials. In the process of work it is necessary to constantly ventilate the room.

As for polymer mastics, they do not burn, do not smell, and do not have a negative effect on the human body. The polymer mastic is liquid enough to be applied with a brush. It perfectly fills all the microcracks and cavities of the concrete surface.

Important point: waterproofing material in the bathroom must be applied to the entire floor and the adjacent walls to a height of at least 10 cm. Do not forget about the treatment of sewer and water pipes.