Among modern finishing facade materials, a special place is occupied by metal siding, a universal material characterized by a variety of textures, qualitative characteristics, and low cost.

Content

- 1 What is siding?

- 2 Siding production, its types

- 3 Basic parameters, dimensions and weight of sheets

- 4 Properties of the finishing material

- 5 Where to use metal siding

- 6 What distinguishes metal siding from different manufacturers

- 7 Kinds of siding by texture

- 8 Metallosiding - colors and features of their choice

What is siding?

Initially, the siding was called a board designed for walling, then the name spread to other materials used to create hinged facades, the immediate duty of which are:

- protection of walls from exposure to weather factors,

- ennobling the appearance of the building.

Modern construction refers to the finishing materials pragmatically, highlighting from their number:

- characterized by strength and reliability,

- having a long service life,

- lightweight, not aggravating the construction of structures,

- featuring an attractive view,

- having affordable for a wide range of consumers.

It is in the number of such materials that are quickly moving along the ladder of popularity and metal siding has got. His popularity is due to the compliance with the basic requirements imposed on the quality of finishing materials and attractiveness - in appearance it is difficult to distinguish from a natural wooden board or stone.

Siding production, its types

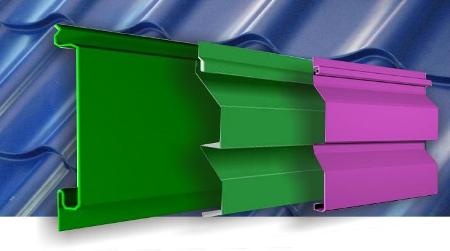

In the manufacture of steel siding, the cold rolled steel method is used. According to the design, the finishing material is a panel equipped with locking joints and fixing slots. To make it attractive, its outer side is covered with a layer of polymeric material (plastisol, polyester, pural) or it is decorated by powder coating.

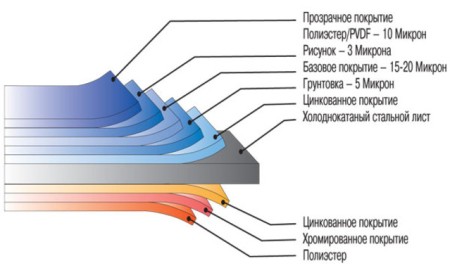

The structure of the siding sheets is multilayered, consisting of a metal substrate and superfine layer applied to it on the wrong side: polymers, priming material, conversion, i.e. phosphate layer, zinc layer, and the front: zinc layer, phosphate, protective - paint.

The finished material is stored and transported in coils.

Basic parameters, dimensions and weight of sheets

The steel metal siding is produced in sheets, the length of which is 4 m, the width is from 0.2 to 0.25 m. With a material thickness of 0, 48 mm to 0, 61 mm, its square meter has a weight of about 2.4 - 3.5 kg.

The advantages of buying a siding include the ability to take the calculated amount of material, i.e. its multiplicity is one.

There are two types of metal selling:

- smooth, holes for fastening which are drilled during the installation,

- with the existing perforation, intended for assembly with the help of screws or nails.

Today, smooth panels are more popular, they are versatile, they can be installed both in the longitudinal and transverse directions, an attractive moment is a wide color range of such material.

For the production of siding can use different materials:

- aluminum, such panels are characterized by lower weight and greater resistance to corrosive processes,

- steel, made from it facing materials have a higher strength ability to resist mechanical loads of all kinds.

Depending on the purpose of the material, there are also some differences:

- Siding designed for finishing the plinth has a higher strength and a long service life, is resistant to the influence of wet environments and temperature changes; the plinth of the metal siding has a rectangular shape, usually a metal siding brick or natural stone; its color is usually more dark, non-marred shades. Use socalled metal scoring under the stone, for example, you can not only to finish the plinth, but the entire surface of the facade.

- Facade it is rational to use for facing the exterior walls of the house, usually its texture repeats the popular natural facing materials.

- Ceiling metal siding It can be used for covering the surface of ceilings in rooms of open type and internal. Often it is used for finishing ceilings in arbors, on terraces, cabins, garages.

To prevent the possibility of deformation of the material at the temperature influence on the edge of the metal panels, there are compensating holes of an elongated shape, the ends are equipped with grooves for joining the panels overlap. On the lower locks there are holes for condensate drain.

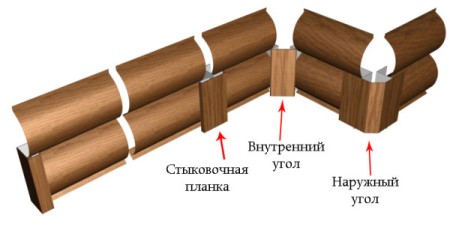

In addition to metal-siding panels, large manufacturers produce additional components:

- ebbs and slopes,

- angular and end elements,

- platbands, interior and exterior corners.

The color of the accessories can match the color of the main elements or be contrastive to it. The use of additional elements allows the design of the most complex architectural forms.

Properties of the finishing material

Although the guarantee for the operation of the siding is given for 20-30 years, in fact it can serve all 50. special care for the surface of the material is not required, it can be cleaned of dirt and dust with water and rags. A large selection of additional elements allows you to perform high-quality, highly aesthetic appearance, installation, including on surfaces of complex shapes.

Interesting design decisions on the surface of the material, for example, metal logging or beam, allow using it in the construction of objects in accordance with the original design ideas, an interesting result in terms of design can be obtained by combining different shades and textures of the surface of the material. It should also be noted a very wide variety of colors and shades, which facilitates the realization of the most daring fantasies of architects.

In addition, metellosiding:

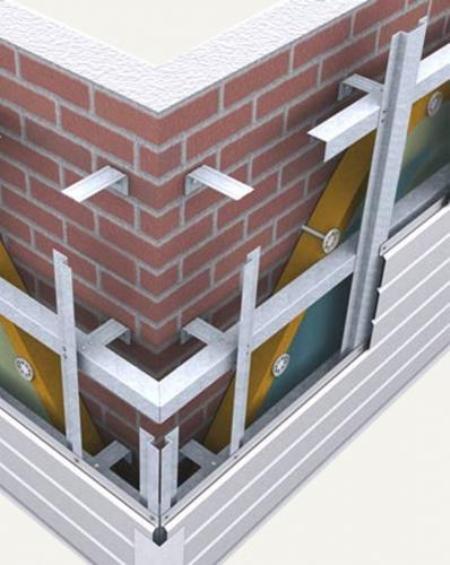

- allows you to organize a qualitative airing of the hinged facade, the walls of the house and a layer of insulation material,

- being under the influence of sunlight does not change the temperature,

- does not change its quality at a temperature of +80 C to -60C.

Mounting metal scoring - the process is fairly simple, it can be performed even by a person without special training.

Among the advantages of metal siding are:

- high degree of protection against corrosion,

- not a propensity to burn,

- resistance to mechanical stress,

- low level of thermal expansion,

- the ability to perform installation work in a short time, and at any time of the year,

- environmental friendliness,

- the possibility of equipping the facade insulation system.

Where to use metal siding

Finishing the facade with metal siding is often preferred very reasonably, especially in cases with a complex configuration of the wall surface and the presence in them of a large number of window and door openings.

The use of this material is also advisable in the event that the territory of the suburban area stagnated with structures in different architectural styles and chaotically - the finishing of each structure, including residential buildings, farm buildings, a fence, a well, etc. metal-siding panels will allow to refine the appearance of the whole site and bring a certain style solution to its territory.

Metal siding is one of the most suitable materials for the restoration of old residential, industrial, public facilities. It is irreplaceable in those cases when strict requirements are imposed on the buildings regarding the level of fire safety, corrosion resistance, ability to withstand the action of active chemical reagents.

What distinguishes metal siding from different manufacturers

The largest domestic producers of metal siding today are:

- holding INSI,

- enterprise North Steel,

- factory in Lipetsk,

- metalist plant (trade mark Grand Line).

The positive qualities of the domestic material are durability and relatively low cost. Material produced by a Finnish company Ruukki has unrivaled quality characteristics and is popular all over the world, produced in Britain by the concern Corus Group - fully complies with high standards of European quality, polyester coating of its surface significantly extends the life of the material. Siding from the American manufacturer Alcoa has an aluminum base, is attractive by a small specific weight and not a high cost.

It is also worth considering the features of some varieties of finishing material. Metallosiding shipboard is distinguished by an original, partially sloping shape, the area of its application is the decoration of facades.

Vertical siding is distinguished by a vertical installation method, the perforation with this mounting is positioned in an upright position, its docking lock has a unique design that prevents moisture from getting inside.

To simplify the construction process, some companies began to produce siding with insulation, its panels consist of several layers, the middle of which is warming, the outer one - decorative, the inner - protective. When using heated metal siding, the installation of an additional thermal insulation system is not required.

Kinds of siding by texture

According to the texture, metal siding can resemble a variety of natural and artificial materials, its surface can be amazingly smooth, reminiscent of the surface of natural stone (marble, brick, granite) or wood. If necessary, it is easy to find a metal siding beam or log, or a shipboard or block house. The quality of the surface and the accuracy of repeating the texture of different materials on the surface of the siding is simply amazing - even near sometimes it's difficult to tell where the stone is real and where it is an imitation.

The main advantage of this material is the opportunity to obtain a facade of the ideal type, no different from created from natural material, but whose service life will several times exceed natural materials, in particular - wood. Care for the siding facade is simple, consists of periodic washing with the help of ordinary water.

Metallosiding - colors and features of their choice

You can immediately see that the metal siding of color is very diverse, in most cases they can be selected directly at the point of sale, with a fairly large order, you can choose any color from the palette Ral. It should be remembered that shades may differ slightly if:

- material is taken from lots of different supplies,

- if it is from different suppliers,

- depending on what kind of coverage the sheet has, for example - a matte and glossy surface of the same color will visually have different shades.

The most popular are:

- cherry and red shades,

- blue colour,

- different shades of green and gray colors.

The encoding of the shades is standard, Ral, only Ruukki uses its own encoding.

In the event that the cladding is subjected to a structure located with the previously finished or it will be necessary to make a partial replacement of the already used facade panels, then there may be some problems with the determination of the shades of the material. Well, if the coding number of the material purchased earlier is preserved. But you can take for the sample a small piece of finishing siding. It will not be superfluous to take into account that with a prolonged exposure to direct sunlight, a certain shade change will occur, i.e. burning out.