For the construction of houses use a lot of materials. All of them differ in their composition and size. In this article I will tell you about ceramic blocks and the construction of a house.

Content

Porcelain ceramic block

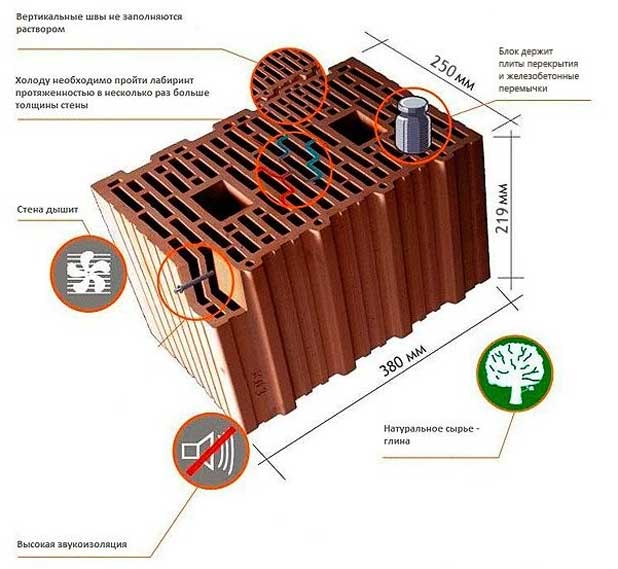

Ceramic blocks are made from the same clay as red brick. The only difference is the addition of sawdust. After the formation of blocks, firing follows. As a result, sawdust burns out, and ceramic blocks become like a stone. The result is a building material with good thermal insulation properties.

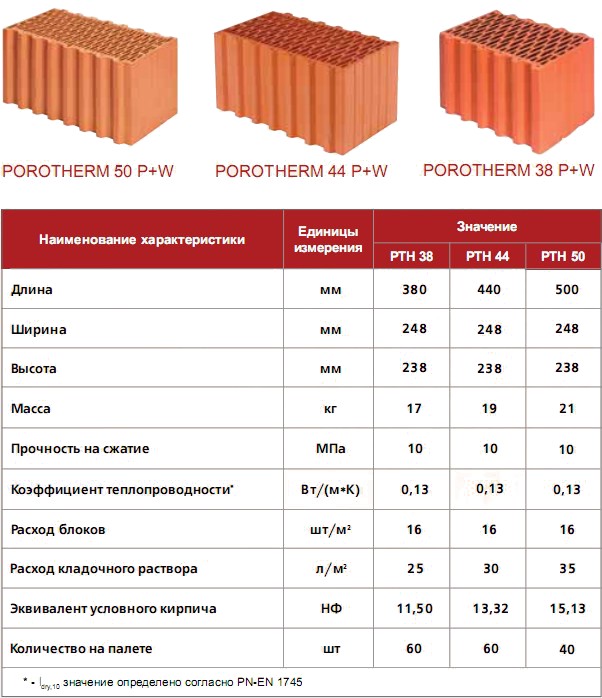

The main characteristics of the blocks are:

- small thermal conductivity due to the presence of voids with a closed volume;

- thermal inertness - walls from this material do not require insulation, because the room maintains an ideal thermal and air balance due to the structure of the blocks;

- simplicity of masonry, which reduces construction time;

- the durability of the blocks will last for a long time from 50 years or more, in contrast to a simple brick with a service life of 25 to 50 years;

- a large block size allows you to spend less material while building walls faster;

- blocks have a low weight, which does not create additional stress on the foundation and walls;

- economical use of mortar for masonry;

- excellent sound insulation due to the structure of the unit;

- fireproof - do not burn and do not emit harmful substances when heated;

- environmentally friendly building material.

For all its advantages, the porous blocks are very fragile and are afraid of moisture. This must be taken into account during transportation and construction (protect from subsoil water).

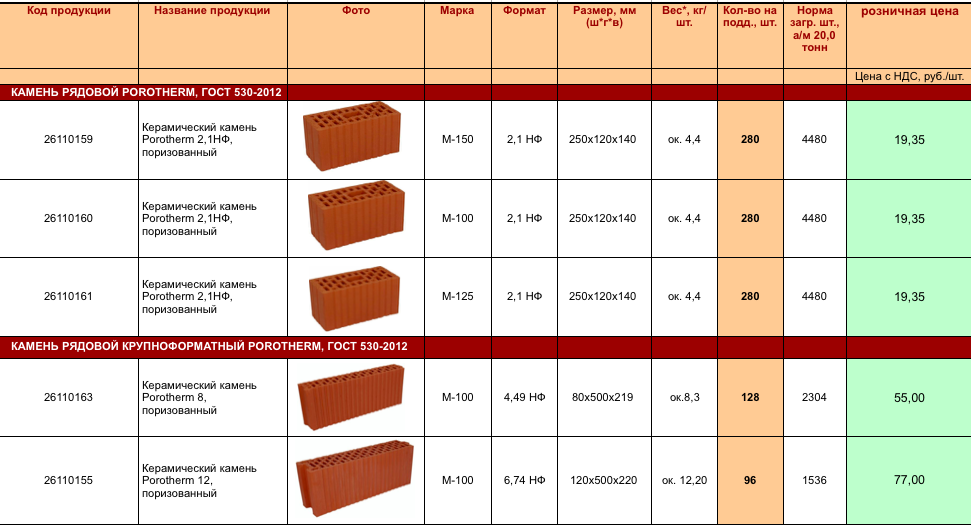

Ceramic blocks price

Prices for this material vary from 11.90 to 139 rubles per piece. A cube of ceramic blocks will cost an average of 3,500 rubles. Of course, this is not the most affordable construction material, but it surpasses many by its characteristics.

Size of ceramic block

Many manufacturers in the manufacture of blocks take into account the convenience of working with them. The following size is popular: 510 × 240 × 215, which is identical to 13.5 pieces of standard brick. Most blocks have the following length: 8, 10, 25, 30, 38, 50 cm. And the width is: 23, 24 and 25 cm. when laying in a brick it is the thickness of the wall. Therefore, manufacturers of ceramic blocks recommend for bearing walls to use bricks 30 cm long, at least, and for interior partitions 25 cm.

Keramooblocks pluses and minuses

There are many speculations about this material, even manufacturers may be inaccurate in the description of ceramic blocks. For the convenience of users, we now present the strengths and weaknesses of this material, and it is up to you to decide on such blocks.

Positive traits:

- the raw material for the blocks is clay, which refers to environmentally friendly components, and hence the products are obtained as safe;

- low thermal conductivity, which is 1/4 of the same index of conventional brick, and this indicates savings in heating in the cold season;

- due to the large size and the system of the comb-groove on the ends of the blocks, the speed of construction increases many-fold;

- the material is light, which does not require the erection of a heavy foundation;

- the vapor permeability of the blocks allows to regulate the microclimate in the room;

- such units perfectly absorb sound vibrations, which indicates good sound insulation in the house.

By cons are:

- high price;

- fragile material, which requires careful transportation and handling;

- erecting walls from ceramic blocks you must strictly adhere to the technology of masonry;

- To fix any objects on such walls it is necessary to use special dowels or anchors;

All of the above indicates that the material is good simply requires a neat attitude.

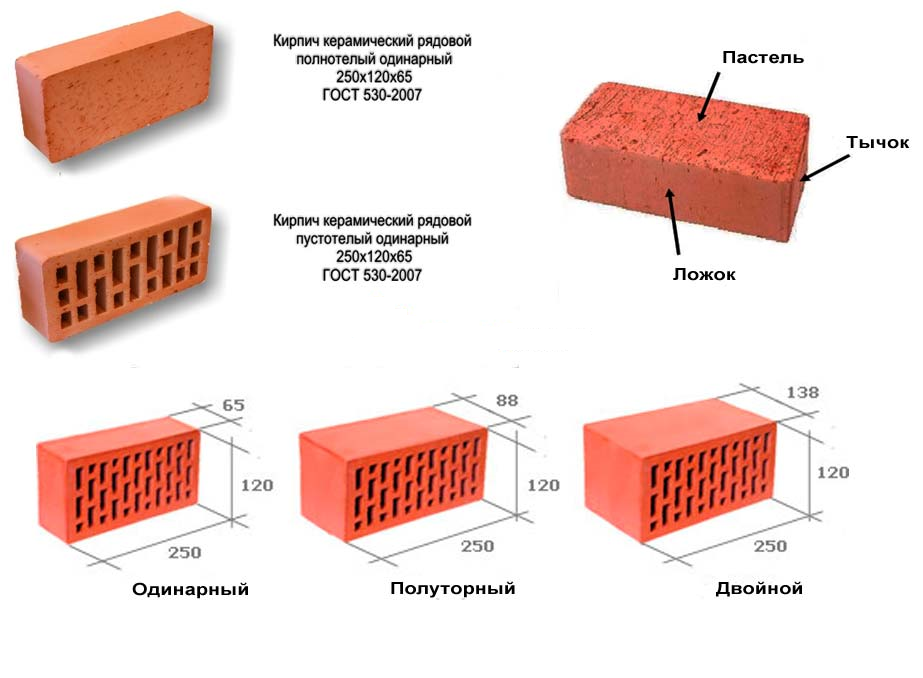

Ceramic brick

This type of brick remains very popular. It is distinguished by good frost resistance, thermal conductivity and strength.

In addition, it is presented in several sizes:

- single;

- one-and-a-half;

- double.

This allows you to choose the best option for masonry. In addition, it can be full and hollow. The latter is best used for erecting power structures that are stressed (bearing walls, columns). Now we offer facing bricks. It is used for finishing facades. It is distinguished by a uniform color and texture. In addition, it can be covered with glaze, which will give the facade an interesting look and will allow you to design it in an original way.

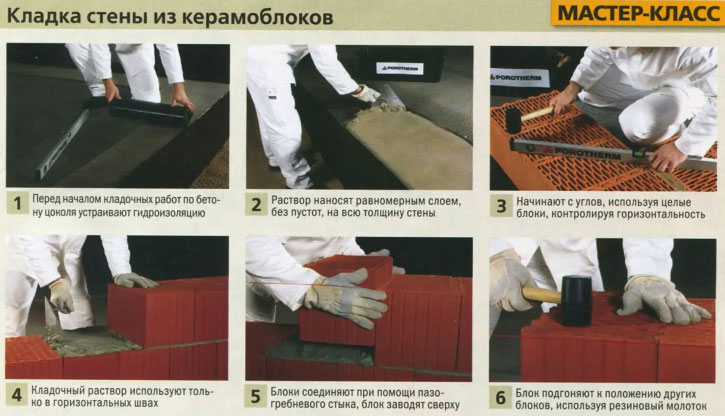

Brickwork of ceramic block

The material is rather capricious to work, so everything must be done carefully. The foundation must be flat. The surface on which the masonry will be made is treated with a waterproof mixture and waterproofing (roofing material) is laid on top of it. Lay it with a ledge of 2 cm inside the building. After doing a laying of a concrete solution with a large thickness of the layer, which will level the entire surface. After the concrete has risen to make a layer of cement mixture, this will allow the block not to sink into the leveling layer. Then proceed to the laying. Begin it with mounting blocks on the corners. In doing so, use the level and kiyankoy for alignment. After stacking the blocks between the corner. After the end of the first row, he needs to stand for 12 hours, which will allow the solution to grasp completely. Each subsequent series must begin with the laying of corners.

Keramoblok reviews

Eugene, 40, Samara.

For three years I built a house of ceramic blocks. I chose a large material. The walls are a pie from the facade plaster with foam, the blocks themselves, the ventilation gap and the facing brick (if you move from inside the building). The house is warm when the outside frost is 30 degrees on the first floor + 18, and in the attic +20. I'm happy, the only thing is to put in mind the characteristics of the material, not filling the side seams.

Sergey, 35 years old, the city of Astrakhan.

I can share my negative experience. We decided to build a house, and for a long time we chose the material. Despite the high cost, they stopped on ceramic blocks. The material brought us horrified, more than 50% of the battle. If less is clear, and it's just a nightmare. I do not want to slander all manufacturers, but they should be chosen carefully and the delivery should be more careful. Then you are lucky, not like me.

Building a house of ceramic blocks, step by step instruction

If the material of the walls is chosen a ceramic block, you need to think in advance whether you will hire masters or lay them yourself. In the latter case, it is necessary to work neatly, but how exactly now we will tell. On the foundation, it is necessary to arrange a waterproofing, after that evenly apply a layer of solution. The installation of blocks starts from the corners, where whole keramoblocks are laid and leveled horizontally. And the solution is used only in horizontal seams, vertical joints are dry with the aid of a spike-groove system located at the ends of each block. For alignment and adjustment of blocks it is necessary to use kiyanku. When using a solution or special glue in the composition of which water enters all work should be conducted up to +5 degrees. If work is taking breaks, cover the top of the wall with a film so that moisture does not get inside. In this way, you can build a house on your own.

Helpful Tips

When working with ceramic blocks, errors should be avoided:

- cut the blocks with a special tool, this will avoid splitting and damage to the material;

- it is not necessary to combine blocks with a brick because of the different thermal conductivity of the material;

- jumpers over windows and doors must be insulated to avoid the formation of cold bridges;

- for leveling the foundation of the masonry it is necessary to use a cement-sand mortar;

- the blocks must be laid with a bandage for the reliability of the structure;

- if on one of the blocks there is no thorn or groove, or a gap of more than 5 mm is filled with mortar, otherwise the vertical joint is dry;

- when stopping works, always protect the masonry from atmospheric moisture.

These simple tips will help to build strong walls without errors.

This article describes ceramic blocks. Their characteristics and sizes are given. In addition, the cost of material per piece and in the cube is given. Using the advice of the article, you can build the walls yourself and avoid mistakes. Successful work