The wooden house has long been a source of comfort, prosperity and harmony. Today, no original, fashionable solutions and innovative technologies reduce the interest in wooden houses. Any project of a house from a roundwood resembles a fairy-tale house. That the fairy tale really became a reality, we will help to learn secrets and features of structures from a round tree.

Content

Features of the round wood

At all times the forest is considered the wealth of any country. Especially if it is a high-quality roundwood, widely used in construction. The main application of round timber is its processing for sawn timber: edged and unedged boards, logs, beams and bars.

The roundwood includes trees with a trunk diameter of more than 18 cm.

The round wood is distinguished by the diameter of the trunk and the dimensions. A saw log called a log, suitable for later sawing on boards. Depending on the size of the log diameter, the forest is divided into a range. The diameter of the logs is measured at the top of the cut.

The diameter of a large group of logs can reach 26 cm, the average group - from 14 to 24 cm, and the shallow from 6 to 13 cm. The length of sawlogs can reach 4 m. Pine wood roundwood is considered the most popular in suburban construction. Logs made of pine logs are distinguished by their excellent appearance, resistance to rotting and cracking, and minimal desiccation.

Determine the quality factor and the quality of the round timber can be determined by the following: a tree should not fall off the bark or traces of soot can be seen. Otherwise, the tree was dried before cutting, or it is a sign of a fire.

For the erection of a log from a round log, use logs with a diameter of 26-28 cm of the same thickness.

To build with their own hands a house from a roundwood means to erect a solid and ecological construction.

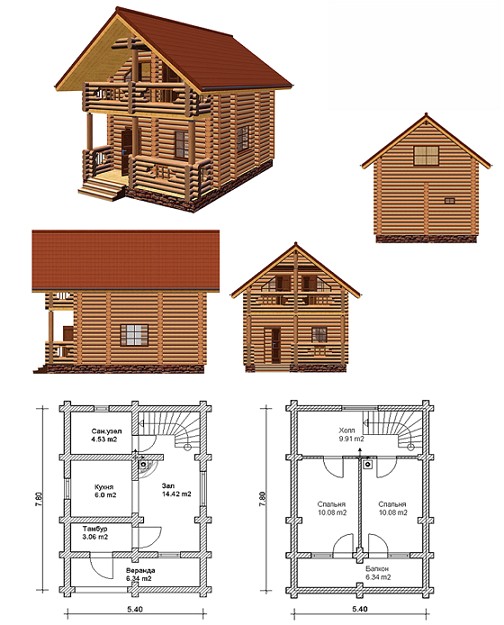

Projects of houses made of round timber

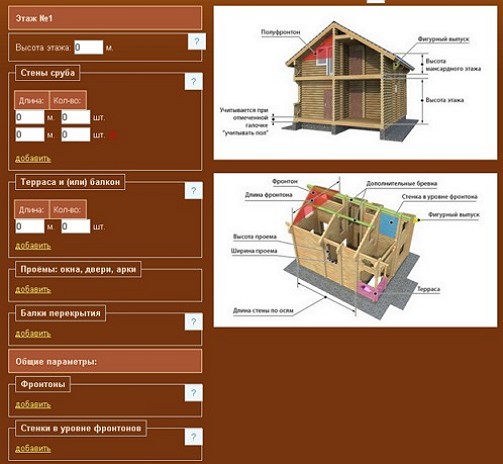

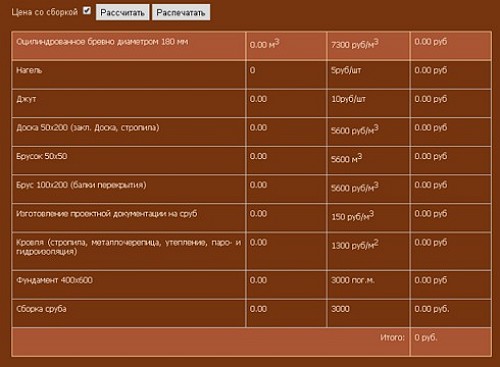

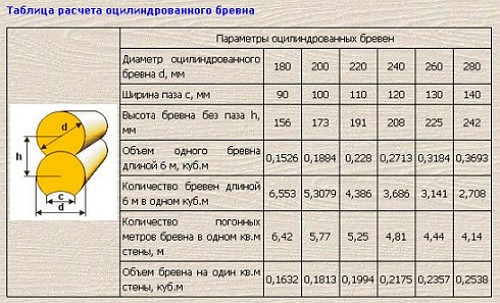

Any project of one- and two-storey houses from a roundwood begins with the choice of logs. In addition, when designing houses from round logs, the main design parameters are: diameter of logs (cm) and volume of rounded logs (m3).

To calculate the parameters, it is recommended to use the On line calculation program. As a result of the calculation, the amount of material necessary for erecting a house from a round log will be obtained: logs (volume per square meter of wall), nagel, boards, timber and bar, jute.

How should I choose logs for construction, and in what way do I install a frame?

choose logs

There are the following types of round logs:

• Cylindrical

• calibrated

• Surfaced.

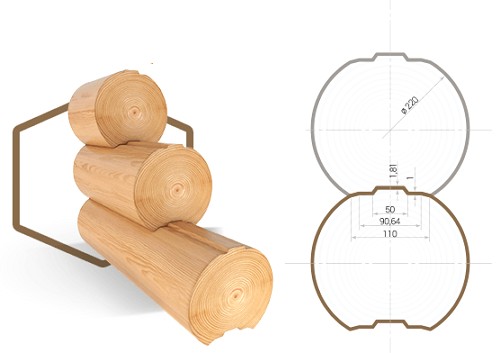

Round logs round logs has the simplest type of processing on wood processing plants, which consists in removing the top layer. In the process of processing remains a dense base of wood, which has an even cylindrical shape. Wood with this type of processing completely retains its qualities of natural material and is ready for use.

Log calibrated is already selected for certain qualities of wood, sorted by diameter. The construction of a frame from calibrated logs is the most preferable option. Walls of houses, baths at erection have a flat surface, due to the proportionality of selection.

The oscured log is a lightly processed wood with a removed layer of bark and irregularities in the form of knots. The protective layer under the bark remains in its original state, preserving its high strength and natural form.

The difference in diameter of the top and bottom of the trunk is clearly pronounced. However, this kind of processing most fully preserves the dignity of wood. It was from this type of wood that huts and houses served for 200 years.

Methods of fastening logs from round timber

There are three ways to fasten and join logs and beams:

• horizontal

• vertical

• Front.

With a horizontal method of fixing a piece of timber or logs are placed on the "cold" joint. As a result of the connection, a gap of a small size is obtained, which is closed.

More technologically, the vertical method is considered, in which a "warm" joint is applied to each other when the beams or logs are applied.

And, finally, the end method allows the logs to be joined into a flat spike located on the inside of the logs.

The angles obtained when the logs are joined together are reinforced with grooves and spikes.

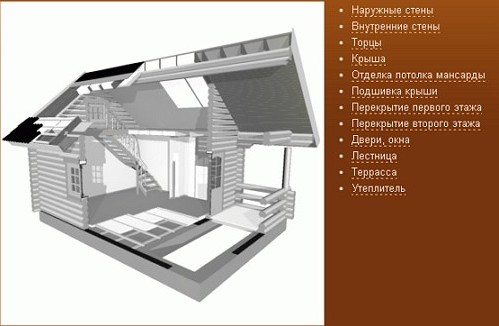

How to design and build a house from a roundwood with your own hands

The design and construction of a roundwood house is based on the calculation of the necessary material and taking into account the characteristics of the soil on the site. It is important to remember that when building a house, you need to choose a foundation or foundation. Recall that for a lightweight construction with low weight and flooring, it is possible to choose a columnar base.

To erect a house from a roundwood on a swampy or water-saturated ground, it will be necessary to erect a pile foundation. For the erection of a one- or two-story capital block on ordinary soils, it is possible to install a strip unground foundation.

Technology of building a house from a round log

When building a house from a round wood it is more preferable to purchase a complete house kit ready for assembly. In the kit, all the logs intended for erection are dimensioned to each other and numbered. Remains only neatly to assemble. The weight of the logs is impressive, so it is better to work 2-3 people.

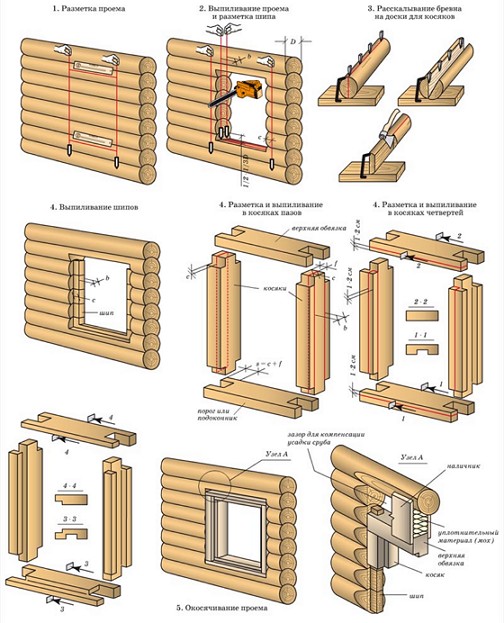

Initially, between the logs, holes are drilled under the nagels, by means of which logs, as it were, string and form a wall. The first to mount nagels, located in the corners, window and doorways. The fixing distance should be 1,5 - 2 m with the log side length, and 10 cm at the window openings. The largest and even logs are used for laying the first wreath.

The lower base is shackled to create a stable laying, and in the log a "bowl" is formed. "Bowls" are semicircular grooves for fixing corners. Having formed a row of wreaths, they make laying of the heater. The erection of subsequent wreaths is carried out with the laying of the roll insulation. Crowns are stacked with the adjustment of the location of windows and doors, adjusting the logs.

After laying the last crown, a frame of ceiling beams and the installation of the truss system are made. The assembled house from the roundwood is allowed to stand up to 6 months, in order for the wood to dry completely, and the shrinkage process was completed.