The quality of the lining of the house is able to transform the house, increase its service life, reduce heat losses and extend the life of all building materials. Facade panels will help to solve the problem of improving the appearance of the building, especially since the front panels can be fastened both vertically and horizontally, both on a flat surface and on a convex one. If you wish to install the front panels yourself, the tips of this article will help you.

Content

Facade panels, types of facade panels

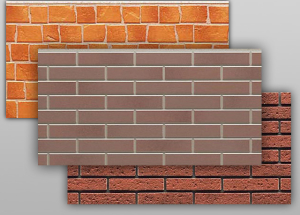

Facade panels are of several types:

- Panels from metallosiding;

- panels for imitation decorative tiles;

- panels made of polyvinylchloride siding;

- panels - siding made of wood;

-Panels for plaster.

Consider the mounting technology of the above panels.

Facade panels - metal siding, mounting technology

Metal-siding panels have recently appeared on the construction market, but because of their high qualities they have gained popularity.

Panels are made of galvanized steel of high quality, the top is covered with a special film that does not burn out for 10 years.

Metallosiding can be a "log", in the form of a "shipboard", etc. It looks externally very beautiful.

Excellent for finishing single-storey houses and garages.

Due to the large weight that increases the load on the load-bearing structure - the decoration of multi-storey buildings is problematic.

To work with metal siding, you need to purchase the following tools:

-electric drill;

- screwdriver;

-Bulgarian;

-Double and screws;

- brace and screwdriver.

Work begins with the stage of measuring the walls of the house.

This must be done to calculate the necessary amount of metal siding.

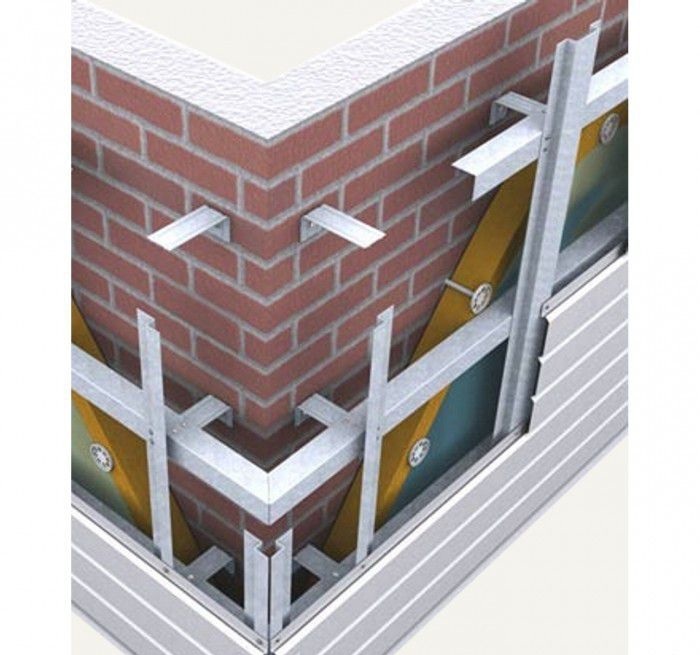

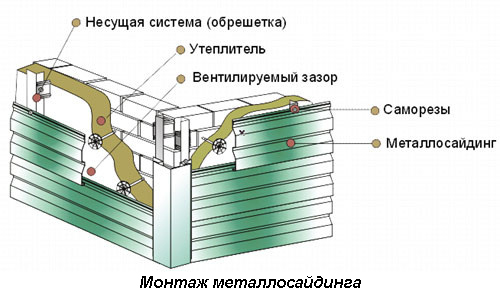

After the purchase of metal scoring and all additional slats, it is necessary to install a frame.

Here, the most important thing is to properly fix the first rack, it is fixed at an angle of 90 * to the ground, all the subsequent racks are attached parallel to the first with an interval of 50 cm.

Dowels are used for fixing.

If the building is supposed to be insulated, depending on the size of the insulation, transverse bulkheads are attached.

In the rectangles that were obtained as a result of fastening the frame, lay the heater.

A heater may be a mineral wool or a styrofoam.

Now they start the installation of metal siding.

The metal siding is fixed with self-tapping screws, the screws are hidden under the next block of panels and the construction becomes monolithic.

Facade panels, panels for decorative tiles

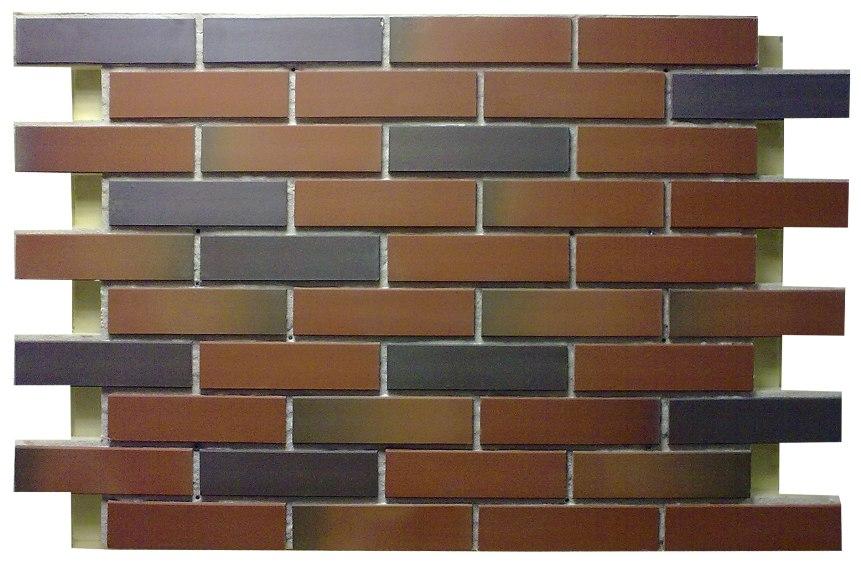

These panels, not so long ago appeared on the construction market, the base is pressed foam, and outside is applied decorative coating.

A great advantage of these panels is the ability to simultaneously warm the house and create an imitation of finishing the house with a natural stone.

The only drawback is the high price.

The unique mounting technology makes it easy and quick, thanks to special grooves, to secure the docking of panels reliably.

The panels themselves are attached using a construction adhesive, the glue is applied with a notched trowel.

A special adhesive solution is applied to the panel, which is then applied to the wall for 3 minutes.

After three minutes the panel comes off, and then, after two minutes, it is glued again.

This technology increases the stability and adhesion of the material.

If during the repeated application, the panel is not glued, then the glue is incorrectly selected, or the wrong portion of the glue is applied.

Panels are mounted from the bottom up, laying the first row, the next stack in 30 minutes, this time-out is necessary for the glue to catch.

Work can be conducted only in the warm season, at a temperature of 20 * C-25 * C.

Facade panels, panels for plastering

These panels are made of pressed foam, have excellent thermal insulation properties, low weight and the ability to create a finished wall microclimate, in which the walls can "breathe".

But panels of this type, easily subjected to mechanical damage, are fastened as well as panels from decorative tiles.

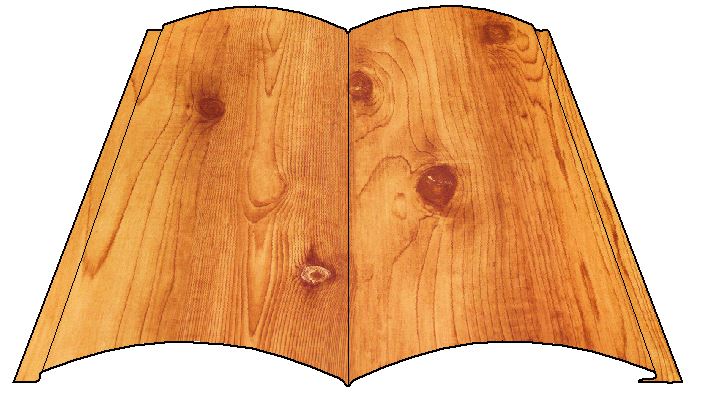

Facade panels, wooden siding

Siding made of wood, as well as metal siding, is used in finishing single-storey buildings, because of its decent weight.

The tree requires constant care, processing with special impregnations, prolongs the life of the siding from wood for decades.

Assembly of the assembly is similar to the installation of metal siding.

The frame can be made, both wooden, and metal from a metal profile.

If the frame is made of wood, it must be treated with an antiseptic. When installing a wooden frame, it is necessary to take into account that vertical racks of wood are not placed on the ground.

If the tree touches the ground, it will pull the moisture out of the soil and quickly rot.

Panels to the frame are fixed with screws.

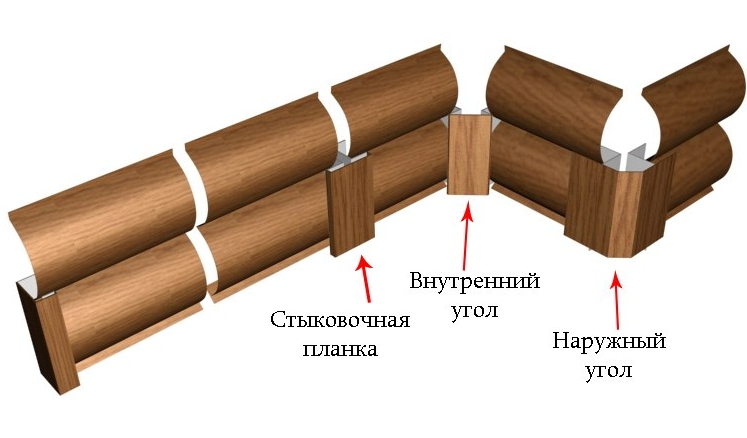

Facade panels, polyvinyl chloride siding

PVC panels are the cheapest and easiest way to install facades.

A wide range of colors allows you to choose the color of panels for every taste. The only drawback is that even from a long distance it can be seen that the house is sheathed with plastic.

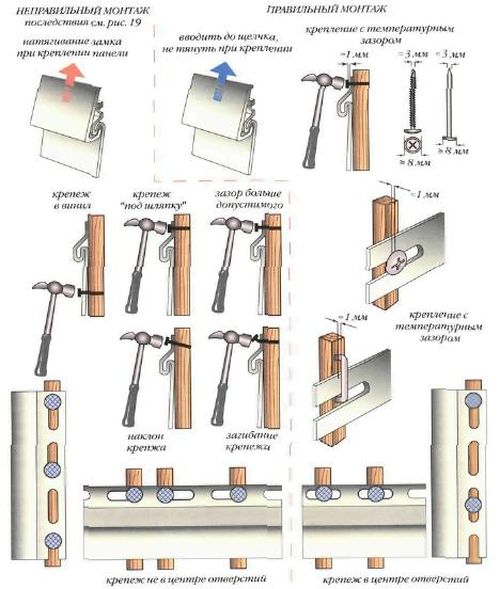

PVC panels are mounted only horizontally.

The most important step is the installation of the first row of siding.

From the correct horizontal of the first row will depend on the appearance of the whole house.

First draw a line of the first row, it will serve as a reference point for further installation, set the starting bar.

It is necessary to install all components, internal and external corners, trim.

On the door and the windows are fixed trims, low tides.

PVC panels are mounted from the bottom up.

Each subsequent panel is inserted into the profile of the previous panel, fastened with screws or nails in the center of the holes.

Fasteners should not be tightened to the stop, as the panel must move freely at temperature differences.

Advice from a specialist

Before starting work, it is necessary to remove all gutters, fixtures, etc.

The panels must be installed so that they easily move both to the right and to the left, overlapping is not necessary.

The last row must be closed with a finishing strip.