Most builders tend to choose materials under a stone or a tree when creating an exterior cladding. However, most natural finishing materials have a high price and labor-intensive installation process. Metallosiding is not one of them.

Content

The outer side of the metal siding with a polymer coating made of polyester, plastisol and pural with practical operational characteristics and original texture diversifies the future facing of the old house or structure.

Choosing a metal siding tree

The increased interest in metal siding will be explained by its good performance, original appearance and availability of handwriting.

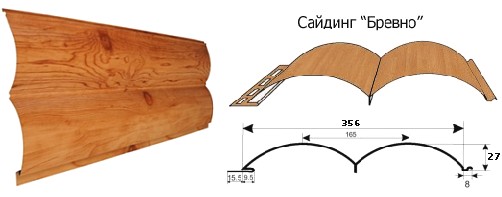

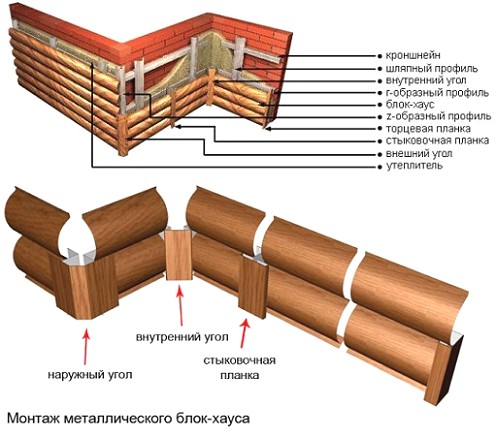

Siding metal under the tree is fundamentally different from existing competitors - vinyl and wooden, the possibility of finishing the walls and facades of houses by imitating a natural log or block house. What is attractive about metal siding, what is it and how is it recommended to select the material? Initially, siding is selected by type of profile.

what types of profiles exist

Siding for a tree is distinguished by a characteristic type of profile:

- metal siding for timber

- Shipboard

- "block house"

- "Eurobrus".

Each type of profile requires a certain mounting direction and position of the nail bar.

mounting direction

Siding finishing under a log and metal siding block house successfully combine the appearance of natural "logs". A simple connecting lock and a gripping fastener allow you to quickly collect walls, facades and fences. Installation of siding under the log and block house from top to bottom.

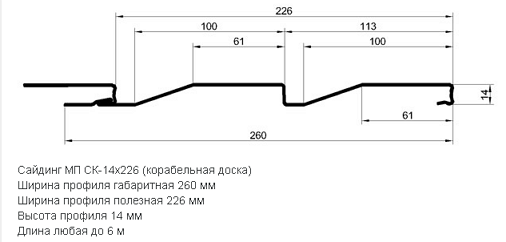

No less attractive profile siding metal shipboard realistically imitates boarding upholstery.

To create the illusion of a wooden structure made of pine allows a secret fastener. By the way, the insignificant cost of siding of this profile in comparison with facade cassettes of ventilations is low. This advantage allows you to produce a budget option for finishing the facade of the house. The board is mounted from the bottom up.

The originality of the real glued wooden beams repeats the metal siding of the beam with a profile width of 100-120 mm.

Metal siding beam is mounted from the bottom upwards, a nail strip from above.

The next selection criterion is technical characteristics.

Technical characteristics of metal siding

Siding metal and additional elements are manufactured in an industrial way from galvanized steel. The finished product is presented in the form of panels of cold-rolled steel with a thickness of 0.48-0.61 mm, reinforced with a polymer coating.

Convenient mounting dimensions of metal siding - length 4-6 m, width 340-550 mm, non-fading ability and non-rusting siding allow it to be used everywhere for exterior decoration.

Structurally the product is multilayered:

- basic covering - 20 m

- characteristic drawing - 3 m

- coating PVDF thickness of 10 microns

- priming layer 5 microns thick.

Thanks to an insignificant Coeff. thermal expansion and high refractory qualities, siding is a promising finishing material. In addition, the improved performance characteristics of the material for metal siding are supported by the profile system and mounting methods.

Any selected metal siding requires a preliminary calculation, the initial data of which are measurements and a schematic drawing of the finish variant.

Calculation of metal siding

Finishing material has limited dimensions and purpose of additional elements. Taking into account the high cost of material, the calculation must be adjusted to an accuracy of 1 sq.m. Powerful on-line calculator support will allow you to calculate the total number of panels, pediments and additional elements for a known area of the cladding.

calculation of panels

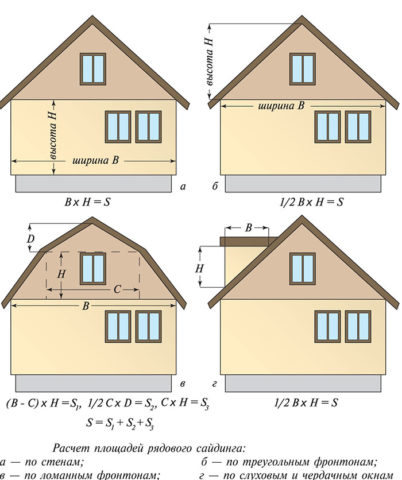

The algorithm for calculating the metal siding panels is based on the parameters of the perimeter of the walls and the length of the angles, as well as the area of simple figures, the formulas of which are involved in the calculation.

The number of panels is calculated by the formula:

Spanels = S walls - S window and doorways

Next to the resulting number of panels add 10% when plating the square of the rectangular shape.

To obtain the number of panels, divide the result by S of the unit strip.

calculation of additional elements

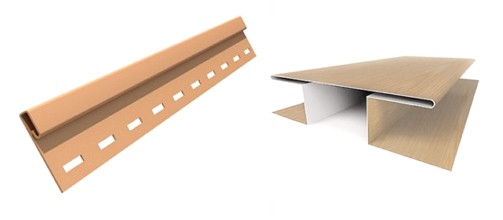

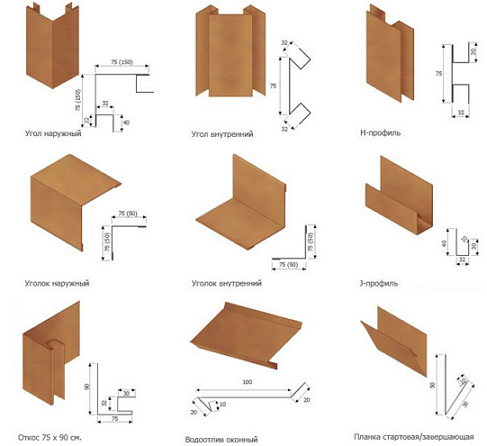

The configuration of the skin by metal siding under the tree will require the following additional elements:

- trims starting and finishing

- connecting and fencing straps

- window frames, trim and outflows

- external, internal angles and chamfers.

Calculation of the starting and finishing strips is made from perimeter data, the calculation of the angles by the number multiplied by the total length and the subsequent division by the length of the profile.

Let's say that the installation of metal siding and the production of works are similar to the technology of the vinyl siding own installation.

Mounting of metal siding with own hand, step by step

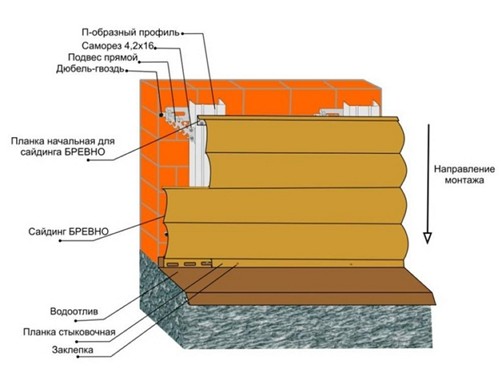

Before starting the installation work, it is necessary to check the closing of the locks at the bottom. Mounting after mounting the starting start in accordance with the direction and position of the nail bar.

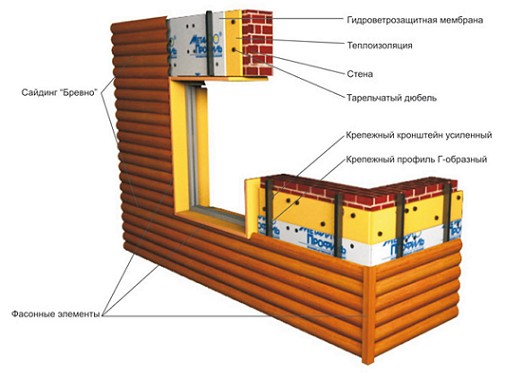

Metal-siding panels have a weight of up to 5.8 kg. To fix and strengthen the collected fragments, a metal crate is installed like a crate for GCR.

erection of crates and bearing profiles

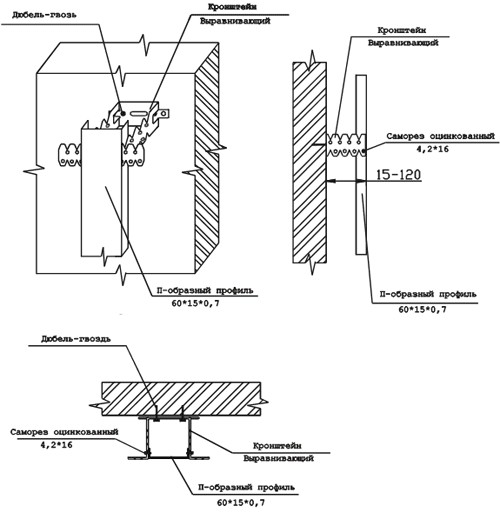

Step 1. We mark the wall, the facade and the pediment under the mounting points of the leveling brackets. For horizontal mounting, the fixing step is 600-800 mm, for vertical - 1000-1500 mm.

Step 2. Install the alignment brackets on the dowel in the marking points.

Step 3. It is recommended to fill the inter-profile space of the crate with a plate heater.

Step 4. On the bracket we string the insulation plates starting from the bottom row.

Step 5. We fix the heater with plate dowels at the corners of the heater plate.

Step 6. We pull the protective film and fix it.

Step 7. We bend the legs of the brackets to a depth of 15-120 mm.

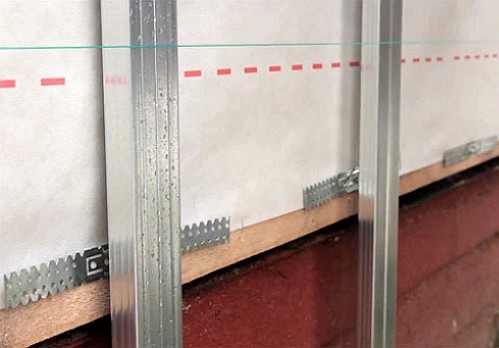

Step 8. On the bent paws of the leveling brackets we install the U-shaped profiles 60x27mm or 60x15mm.

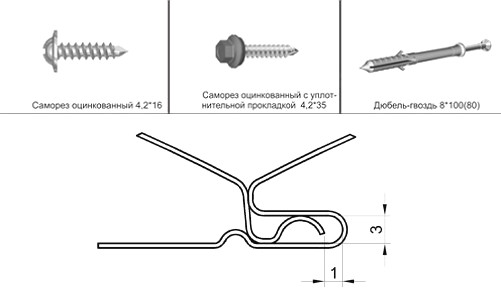

Step 9. We fix the profiles with galvanized self-tapping screws 4,2x16mm.

installation of the starting plate and subsequent panels

As the starting strip for metal siding, the supporting guide panel acts on which the fastening is made by means of the lock of all subsequent laths.

Step 10. Depending on the type of metal siding profile, we set the starting bar with the nail strip and specify the direction of the installation of the subsequent panels.

Step 11. We hammer fixing nails into the holes of the nail strip, leaving a gap between the panel and the nail of 1.5 mm.

Step 12. Subsequent panels thread on the installed, connecting and securing the lock.

The placement of the first panel is carefully adjusted by level. As the following panels are installed, it is recommended to check the horizontality and verticality.

How to carry out the installation of a metal beam log, shown in the video.