Among the many types of modern flooring, the terraced and the floorboard remains one of the most popular. If the flooring needs to be done in the open, the best option is a terracotta board, since it does not rot, is not affected by atmospheric phenomena, does not slip, is durable. Price of the terrace board for reference on a specialized website. If the floor covering is performed indoors, the best option is the floorboard. The reasons for this popularity of the plank floor are obvious: it has low heat output, a long service life, laying the floorboard is not difficult, and it costs less than parquet and laminate, the plank floor does not require special maintenance during operation. It is quite possible to make a wooden floor by yourself, thus saving - another plus of this coating. Below we consider the requirements for the material and the technology of laying the floorboard.

Content

What to look for when choosing a floor board

In most cases, the floor is covered with a board of resinous coniferous wood, since its value is relatively low, if compared with hardwoods, for example, the same oak. But, on the other hand, the hardwood board serves much longer, and is stable and better resists aggressive factors. Whatever kind of tree you prefer, the floor board should be well dried and treated with anti-pest, fungi and mold.

Many developers prefer to make a floor from a pine board. This is a pretty good alternative to deciduous species, and the pine is much cheaper than hard hardwoods.

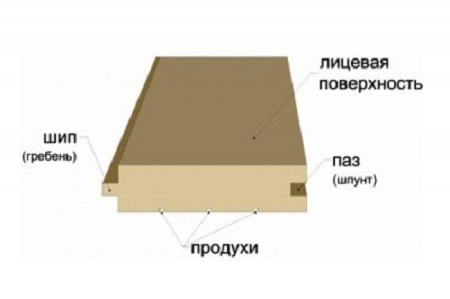

Pine is a traditional material, durable and durable. Pine boards are almost never treated with chemicals, so this material is considered environmentally friendly. Pine board, intended for the floor, usually has a width of about 14 centimeters, and in length - about 6 meters. Humidity of the floorboard should not exceed 10 percent, for one meter of material several knots are allowed, provided that they are "live" and do not fall out. The board must not have any misalignment along the plane, it should not have a deviation along the edge and thickness.

How to lay the floorboard

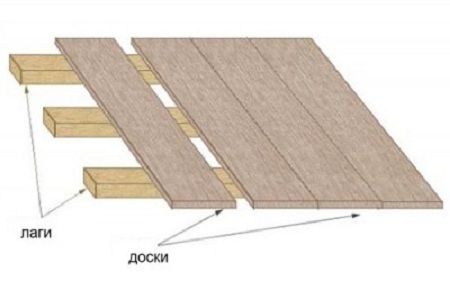

The board is mounted in two ways. The first, the traditional way - the wooden floor is mounted on wooden lag bars.

Second - the board is fixed to the base with screws or glued to the glue.

Laying a wooden floor on logs

If the ceiling height in the room is more than three meters, or there is a wooden floor between the floors, then the wooden floor is preferable to lay on the logs, since the height of the floor together with the lag is 8 to 15 centimeters. The board must have a thickness of at least 3 centimeters.

The technology of laying the floorboard on the lags is as follows:

If the laying of the wooden floor is carried out on the first floor, you need to take care of good waterproofing. Most often, a ruberoid is used for this purpose, the sheets of which are soldered at the joints and overlap the walls.

The next stage is the installation of a log. If you need a reliable grip lag with the base, then their thickness bars should be 5-7 centimeters. When the logs can not be attached to the base, then a material of a thickness of at least 7 centimeters is used. In the case where the thickness of the floorboard is 3-3.5 centimeters, the distance between the lags should be from 60 centimeters to one meter.

Material for logs is necessarily treated with an antiseptic. If the lags are adjustable, then they must be installed only on a reliable, even and fairly firm base, for example, on a concrete screed.

To prevent the occurrence of the so-called "drum effect", you need to make a soundproof floor. Best for this purpose are suitable: glass wool, mineral wool, coal slag and, of course, expanded clay. To improve the efficiency of the soundproofing, laminate substrate, parchment or synthpon is placed between the lag and the board.

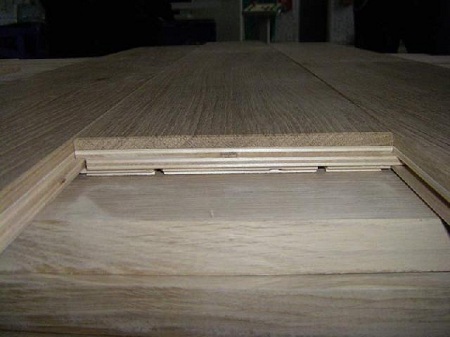

Laying the floorboard is done by combing forward, groove on yourself.

The first board is screwed with screws or screws so that it can be covered with a plinth. A few more screws are twisted at an angle into the ridge. If the floorboard is short, joints must always be on the lags. The final stage of work - polishing the finished floor and coating it with varnish or paint.

Grind the floor several times in different directions: across, along and along the diagonal.

Since for the board floor is mainly used wood of coniferous species, it is not difficult to grind it. In the process of grinding, wood picks up the pile, so the surface is ground several times during the grinding process. Finishing grinding is performed only along the fibers with fine sandpaper.

To cover the wooden floor from coniferous species it is strongly recommended to use a varnish, which gives the material an increased strength, this in some measure compensates for the insufficient hardness of coniferous wood.

The varnish is applied several times (at least two). If the pile has risen after application of the first layer of lacquer, it is necessary to wait until the varnish is completely dry, peel the surface with fine emery paper, and apply the varnish again.

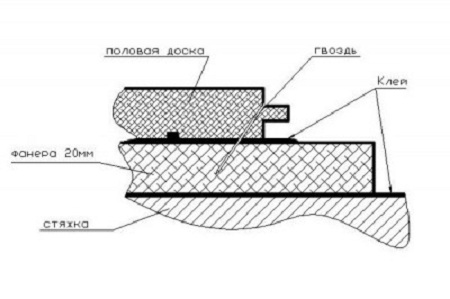

When the plank floor is fixed to the base with a glue solution, the principle of operation is almost the same as when laying a parquet.

The only difference is that one glue is not enough, and the board needs to be attached with screws. The heads of self-tapping screws are concealed using special plugs. This method of installing a floor board is recommended for rooms with relatively low ceilings, since the height of such a floor is small. If the floorboard is fixed with glue, make sure that the base and the board itself are perfectly even. On the base, a layer of waterproofing must be installed and laid with moisture-proof plywood.

Choosing the glue for the floorboard, you need to consider several points. For example, slats about half a meter in length can be glued together with any suitable glue for wood, for example epoxy, polyurethane or dispersed. But if the floorboard is made of beech or expensive exotic wood species, the use of dispersed glue should be discarded.

In the case where the length of the bar exceeds one meter, for its fastening apply glue based on synthetic resins, epoxy-polyurethane or two-component polyurethane adhesive compositions.

In any case, the adhesive composition for the floor should provide maximum strength of the joint and at the same time be sufficiently plastic. These requirements are met single-component and two-component polyurethane formulations, as well as MS-polymers.

Basis for plank floor

The wooden floor can be mounted on a concrete floor, old wooden floor, on a wooden floor and on logs installed on a concrete screed. Each of the bases has its own specification.

Before you start working on the floor, all load-bearing structures must be ready, the windows and doors are installed, the screed and the walls are leveled. The room in which the floor will be made must be well dried, humidity exceeding 40% is not allowed. The level of humidity without special difficulty is determined by special devices. In the absence of such, you can use the proven folk ways:

- With the help of polyethylene. The material is attached with adhesive tape to the concrete surface, and removed after a day. If there is a wet spot left on this spot, the concrete is still wet.

- Using a rubber mat, which is pressed against the screed by a heavy object. If in a day the concrete in this place has darkened, then the humidity level is still quite high.

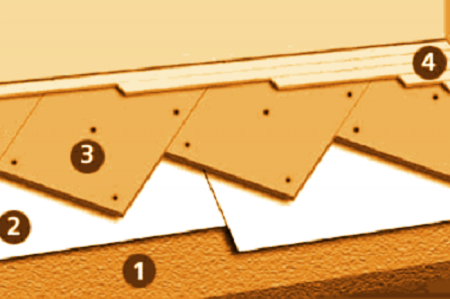

Laying a wooden floor on a concrete foundation

At the first stage of the work, a watertight barrier is made between the board and the concrete foundation. To do this, a layer of ground mastic is applied to the concrete base, or polyethylene film is laid. Mastic is applied with a roller, if necessary, a solvent is used. The film is overlapped, the gaps are not allowed. Using a 2-3 mm thick polyethylene film is the best option.

On the concrete basis the floorboard is laid in two ways:

- On wooden bars.

- On the plywood.

The moisture content of wooden lags should not exceed the permissible norm of 18-20%. Bars to the concrete base are screwed with screws. In order to avoid damaging the communication wires laid in the concrete during the fastening process, you can abandon the screws and glue the lugs with bituminous mastic, which will also act as a waterproofing. Between the lags lay a layer of insulation. Legs before laying the board covered with plastic wrap.

For a plywood base, a moisture resistant material 18-20 mm thick is used. The sheet of plywood, having standard sizes of 1220x2440 mm, is cut into strips with a width of 400-600 mm.

The cut strips are fixed to the base with dowels or screws. Most often, plywood strips are placed diagonally across the room.

Before laying the floor, the plywood base is carefully sanded with a tape machine. After that, all the dust and dirt is thoroughly removed from the surface of the plywood, and the laying of the floorboard begins.

Mounting the floorboard on the old plank floor

Used only if the old floor is strong enough. If not, it must be dismantled. To begin with, the old coating is thoroughly grinded by a machine. A tape with a grain size of at least 40 is used. The moisture-proof polyethylene film is placed on the old coating (in case the old floor does not have the necessary moisture and thermal insulation properties).

Before laying over the old covering the floorboard, make a plywood flooring. The thickness of the flooring should not be less than 12 millimeters. Plywood coating is polished, all dust and dirt is removed from the surface. The easiest way to do this is with a conventional household vacuum cleaner, then wipe the surface with a soft slightly damp rag.

Wooden floor installation

The floorboard is released from the package, and kept indoors for at least a week to avoid deformation.

The board is attached with screws to the base. To pile the next board freely fit into the groove, the screw is heated to a depth of several millimeters. To prevent cracking of the board, it is better to drill holes for the screws. If you do not use moisture-proof film during laying, you can fix the board with parquet glue. But more often than not this is not enough, and for better adhesion it is still recommended to use self-tapping screws.

To fit the boards as tightly as possible, wooden wedges beat the perimeter of the room between the wall and the board. Particularly zealous in this case is not worth it, the gap between the wall and the board should not exceed 10 millimeters.

Wood floor grinding

It is necessary that the floor surface before the application of varnish or paint is smooth and smooth. The heads of the screws are necessarily heated sufficiently deep so that they do not interfere with the grinding process, and do not damage the tape. Angle grinders and surface grinders are used for grinding. The corner machine is used to work in hard-to-reach places, surface grinding is used to work on the main surface of the floor. When hand grinding work a cycle or a wooden bar, wrapped with sandpaper.

Maintenance of board floor in service

To ensure that the floor surface does not lose its "commercial appearance" during operation, periodic maintenance is required, including regular dust removal and wet cleaning. From scratches and deformations, the board is protected with lacquer, grease or special impregnating solutions. The renewal of the plank floor includes grinding and priming, followed by the application of a layer of paint or varnish.

Lacquer is considered one of the most reliable means of protecting the surface of wood. Today, manufacturers offer a wide variety of varnishes on a water basis with the addition of polyurethane and acrylate. For a beech or oak floor, lacquers on synthetic solvents are more suitable. The main drawbacks of any varnish are uneven distribution during application, toxicity and a sharp odor. In addition, any lacquer coating is inevitably erased with time.

Step-by-step lacquer coating

- The surface of the floor is thoroughly sanded and cleaned of dust and debris.

- The prepared surface of the floor is treated with a decorative restorative solution, which gives the board a fresh, attractive appearance.

- Apply a coat of primer. The coating must be completely absorbed and dry.

- The main layer of varnish is applied in several layers after the previous layer has dried completely.

- The last layer is applied after the removal of bubbles and unevenness.

If the room is intensively maintained, the varnished floor covering will need to be updated periodically. In addition to varnishes, various oil solutions based on olive oil and natural resins are often used. In this case, to maintain the floor in good condition, it is regularly impregnated with olive, which ensures the strength of the board to damage and resistance to moisture.

To emphasize the texture of wood and preserve its natural appearance, you can use a toning mixture before applying the varnish.

As you can see, laying the floorboard with your own hands is a simple matter, requiring only accuracy, exact compliance with technology and the use of simple tools.