On the need to create a filling floor in suburban homes, apartments, garages, with construction of warehouses etc. there is enough information. But each time this question makes you wonder which flooring is preferable to create, cement or gypsum. To understand this is not difficult: in order to avoid mistakes, systematize all the acquired knowledge and make a fill yourself.

Content

Why is a bulk floor necessary?

The process of creating a floor or screed base involves using a self-leveling mixture. The floor is the kind of screed with which the maximum leveling of the surface is achieved.

Therefore, to the question: "What is the need for a flooring?" - you can answer unequivocally - for leveling the surface when installing a floor covering. The ultimate goal in the installation of the floor is an ideal horizontal surface for subsequent finishing. However, when carrying out work on the creation of the floor, errors may arise that will lead to poor-quality filling and the formation of cracks. To avoid this, it is necessary to carefully prepare the working base for the forthcoming pouring and to study the technology of the filler floor.

Before tackling the self-leveling floor device with your own hands, it does not hurt to find out the definition of "screed". The main mistake in the design of the filling field is the lack of knowledge of the differences between the filling floor and the screed. But, ignorance of the basic concepts does not relieve from responsibility for their acquisition and the chance to receive such knowledge.

What is screed and filler floor

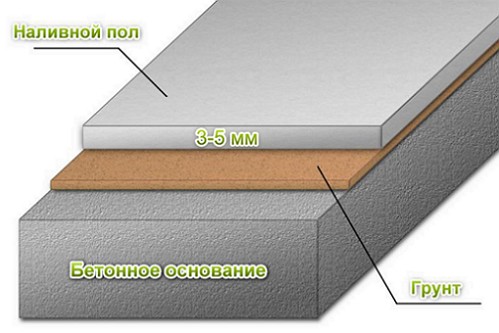

A screed is considered a sand-cement base, the main function of which is to create a strength of the coating. The filler floor is a kind of "horizon" made of a mixture, no more than 3 mm thick, the main function of the filler floor is damping.

Here the natural question creeps in: "Is it necessary to use a dry mix of a bulk floor that has a significant value if it is possible to eliminate the unevenness of a cheap cement screed?". It's time to find out more about the types of flooring and mixtures used in its installation.

Types of bulk floor

There are the following types of self-leveling floors:

• based on cement and gypsum

• based on a polymer binder.

For residential premises, floors are to be filled on the basis of cement or gypsum for subsequent finishing. Floors based on epoxy or polyurethane polymers are used for administrative, industrial and commercial premises. Depending on the type of room, dry or wet, the required thickness of the floor is selected. Recall that technologically the minimum thickness of the floor is 3.5 mm.

Mixtures used for the device

Mixtures for the floor-level device used solely to create a leveling layer are not popular due to the large material consumption. Such a bulk floor, the material consumption of which is significant, can be successfully combined with cement and concrete screeds. Therefore, in order to reduce the cost, a cement-sand screed is used as the main leveling layer.

Chemical additives and components of the screed allow to use it when creating a filler floor that has a gypsum composition. It is necessary to distinguish mixtures for the preparation of cement and gypsum floors in bulk.

cement floor

Cement floor is a self-leveling thin-layer (up to 40 mm) cement mixture on cement basis. The main characteristics of cement flooring are:

• compressive and flexural strength, MPa

• strength of adhesion to concrete, MPa

• abrasion, g / cm2

• layer thickness, mm

• moisture resistance.

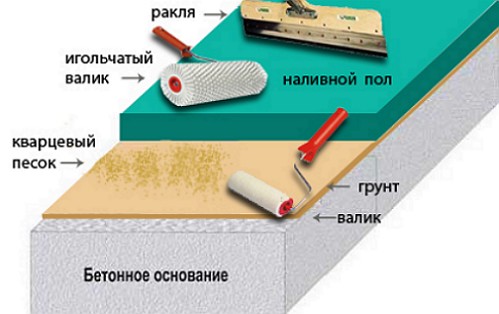

The basis of the composition of the cement floor is cement, so floors of this type are arranged in living quarters. The process of creating a cement floor is composed of the stages:

• preparation and priming of the surface

• preparation of the working mixture

• Filling the mixture.

The ready-made working solution for pouring has a suitability for an insignificant period of time, namely 30-40 minutes. Depending on the area of the floor to be filled, the mixture is divided into several parts and the floor is poured gradually.

gypsum floor

The gypsum floor is designed for leveling a concrete surface and creating a foundation for finishing. This is a thin-layered gypsum mixture. Unlike the cement flooring, the gypsum floor is less moisture resistant. Comparative technical data show that the gypsum fill floor is recommended for floors with a thickness of up to 30 mm.

The gypsum floor is fragile and not compatible with tile adhesives having a cement base. The main advantage is the speed of application and the cheapness of the technology. Gypsum filler quickly dries to the required condition.

The device of self-leveling floor with your own hands is here!

Which sex is better

When you create a self-level floor with your own hands, it's easy to say which gender is better. In this case, the evaluation criterion should be based on the conditions for the subsequent operation of the filling floor and the cost. If you want to arrange a bulk floor in residential premises with low humidity, preference is best given to the gypsum bulk floor. In addition, it is necessary to take into account that when working on the floor of the filler, working layers will be created, according to the characteristics of which it is possible to draw certain conclusions.

Layers of bulk floor

At the device of a bulk floor use the mixtures creating layers:

• basic

• average

• finish.

The base layer is intended for preliminary equalization of the prepared working surface of the floor. This may be irregularities or depressions of mechanical origin, as well as slopes reaching 80 mm.

The base layer is the basis for the middle and finish layers. A feature of the base layer is the possibility of applying a layer of up to 80 mm thick and a significant strength after the final drying. The time of complete drying is 12 hours. The base layer is used for concrete, cement and gypsum bases.

The middle layer is designed to eliminate unevenness and leveling of concrete, as well as cement-sand bases with locations and differences up to 30 mm. The middle layer is the basis for the final floor covering of gypsum or cement. A feature of the middle layer is the application of a layer up to 30 mm. The time for complete drying of the layer is 4 hours.

The finishing layer is the final thin-layered version of the leveling, assuming the subsequent laying of floor coverings. The feature of the finishing layer is its insignificant thickness up to 10 mm, the time of full drying is 4 hours and the high strength of the coating is ensured.

The main errors occur when the technology of creating floor layers is not observed.

A more advanced technology for creating a filler floor is presented in this video.