Today, fundamental solutions for the insulation of monolithic structures using land and expanded clay give way to simple and easy technologies. Now there is no need to create a powerful sand cushion for the convenience of warming the foundation of the house. In the course are dense synthetic insulation - polyurethane foam, expanded polystyrene and its derivatives. Take advantage of useful advice in the manufacture of insulation.

Content

Do we warm the foundation of the house?

It is known that the foundation of any structure and structure is the foundation, which at the design stage is carefully calculated and erected in accordance with strict technology. As a supporting structure, most of the foundation is located in the ground.

However, the insulation of the foundation from the outside and from the inside is a pledge of comfortable living and long-term hassle-free operation of the house. The question of the expediency of warming the foundation, proper thermal insulation and waterproofing of the underground part of the house (basement and basement) minimize the negative impact on the foundation.

Recall that there are many ways that solve the problem, how to warm the foundation of the house.

Warming produce:

- at the stage of concrete pouring (fixed formwork)

- after the end of maturing the casting with concrete by excavating the existing vertical foundation.

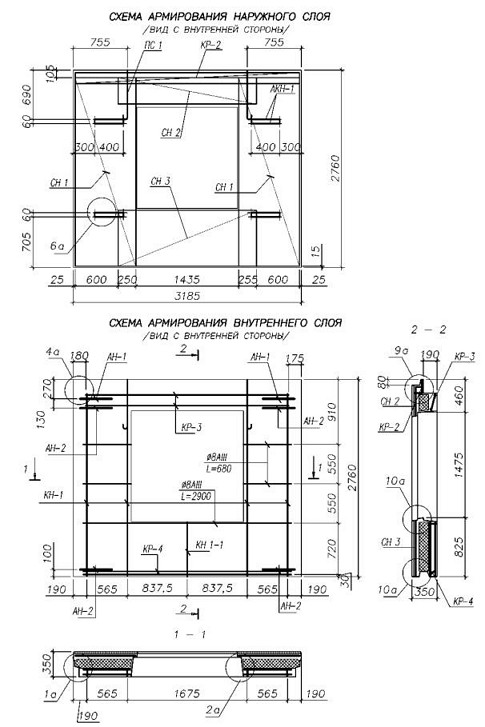

The best option for insulation at the stage of foundation pouring is considered to be a fixed formwork with the use of expanded polystyrene boards.

After the foundation is poured, the classic way of warming is considered a pile of expanded clay layer with subsequent screed. However, these methods are laborious and extensive.

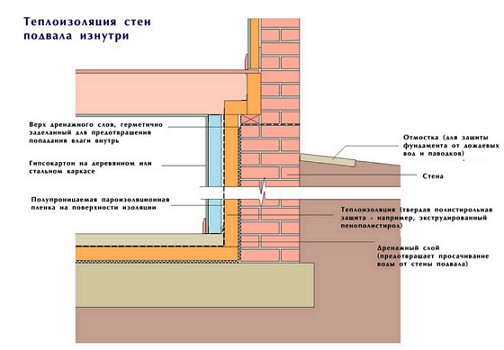

All methods of insulation are finish finishing activities based on the general rule: before the beginning of the insulation measures, the foundation of the house must be provided with a general waterproofing. The basement can be insulated from the outside and inside, using a backfill thermal insulation, and as a heater for the basement - polystyrene foam, expanded polystyrene, polyurethane foam and foam foam.

Helpful Tips

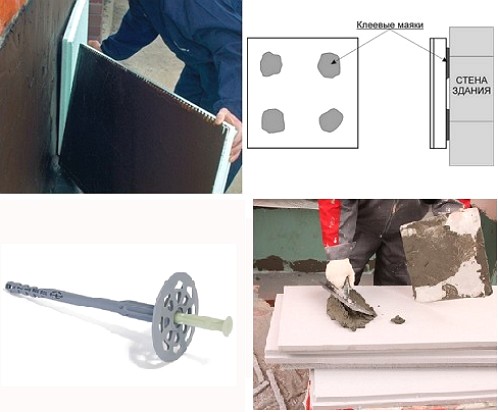

The practice of finishing works suggests that the installation and fixing of the foundation insulation in the form of plates of expanded polystyrene or penopolix is a simple exercise. The main thing is to bring the surface of the finish coat to the required state.

The accumulated experience and knowledge on the installation of light plate materials becomes the most important: selection of adhesive composition and introduction of a layer of reinforcing mesh.

The video will tell you about the necessity of the insulating measures of the basement.

Technology of warming the foundation, what materials are the foundation

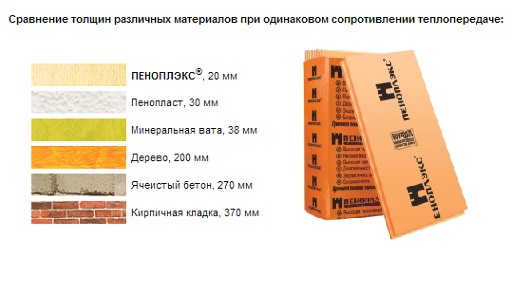

The development of the chemical industry has led to the widespread use of synthetic heaters. Synthetic plate heaters made of expanded polystyrene, polyurethane foam and penoplex are widely used for vertical and horizontal insulation of the basement, basement and basement.

vertical insulation technology

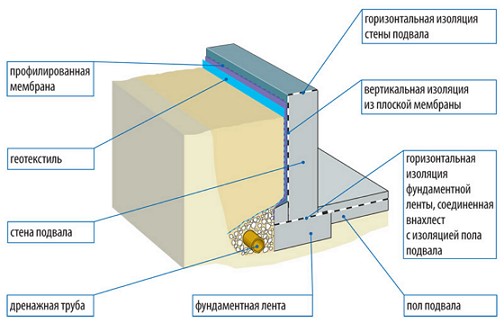

It is necessary to distinguish between vertical and horizontal type of foundation warming.

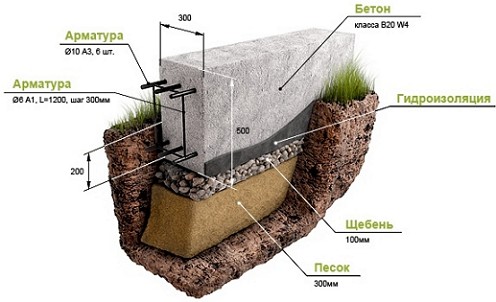

The technology of vertical insulation is used for monolithic tape foundations. With vertical insulation, the existing foundation is dug out and cleaned.

Then, using a water-based mastic, a waterproofing layer is created and a plate heat insulator is installed.

For monolithic foundations preference is given to horizontal thermal insulation technology.

horizontal warming technology

Horizontal insulation is based on the filling of a sand cushion, followed by pouring a small layer of concrete and installing a plate warmer.

Plate heater

The technology of mounting a plate heater is the same for all materials. The difficulty lies in justifying the choice: where the use of a penoplex is suitable, the possibilities of foam plastic are limited.

basement insulation with expanded polystyrene foam

Foam sheets are still in demand as an inexpensive insulation. Unfortunately, the toxicity of the material during heating and the attachment of rodents to the foam and polystyrene are not taken into account. Specialists recommend giving preference to expanded polystyrene extruded boards, which are distinguished by their high strength and density, as well as a convenient form for self-assembly.

Warming is conditionally divided into insulation measures of the underground and basement parts of the foundation.

underground - we heat underground part

The technology of warming the underground part of the basement consists of the following stages:

- preparation of the foundation, including waterproofing, and the choice of expanded polystyrene plates

- installation of plates to the underground part of the foundation with the use of glue and plate dowels

- protection of the surface of the plates from the outside (reinforcing mesh and wooden boards).

For affordable insulation technology, sheets of foam are chosen from plates with a thickness of 50 mm and above with a rough surface for better adhesion of the putty mixture. Then, we choose waterproofing and putty mixes, with which we prepare the foundation walls for installation. The existing chips and potholes are filled with a repair and waterproofing mixture.

Material without special effort is mounted on a special glue (polyurethane, acrylic and cement base) outside the basement and inside from the basement. A sheet of expanded polystyrene or expanded polystyrene is fastened with plate dowels at the rate of 6 dowels per standard sheet. The depth of laying the dowel is chosen according to its length (up to 50 mm). The final fixing in the prepared holes is made by a nail, which is flush with the plane of the insulation sheet. Joints seal the sealant.

useful tips

Simple at first glance, the method of insulation of the base with expanded polystyrene and installation of foam polystyrene plates is cunning. With penolyolystyrene, in view of its chemical composition, organic materials (acetone, gasoline and mineral spirits), as well as organic-based glues, should not come into contact. Mixtures simply begin to destroy the structure of expanded polystyrene. To restrict access to the rodent material, it is recommended to install a metal reinforcing mesh with a mesh size of up to 5 mm in the light.

basement warming

The basement (aboveground part) of the basement is also subject to thermal insulation.

The technology of warming the basement part of the house is similar to the measures for the warming of the underground part. Mounting plate material is carried out using a special glue.

How to install a plate material with vertical insulation is shown in this video.

basement insulation with polyurethane foam

Practical, in terms of installation and perfect technology is the insulation with polyurethane foam (PPU). Stunning characteristics of thermal conductivity and the method of spraying are the best way to warm the foundation. In addition, there is no need for additional preparation of the surface before spraying.

After the foam polyurethane foam is finished, the monolithic basement is guaranteed. Clearances and bridges of cold are absent, as well as microcracks or crevices on the insulating surface of the foundation of the wooden house.

In conclusion, we recall that the life of the plate heater is 25-30 years.

Helpful Tips

At present, thermal insulation technology with a reflective layer has been added to the existing thermal insulation technologies for slab materials. This technology can be confidently considered highly effective, because the insulation, which is a plate material with a reflective layer, is applied to any surface using liquid nails.