The appearance in our everyday life of practical and inexpensive building materials, we are obliged, primarily plastic and plastic products - to panels. A worthy combination of "price-quality" allows you to perform finishing works using plastic panels quickly, reliably and attractively. Panels made of plastic are quite capable of creating a modern interior not only for living space, but also found wide application at finishing of offices on a turn-key basis. Of course, to make repairs, you can use the services of specialized construction companies. But if you want to make your own hands on a ceiling made of plastic panels? Then this offer is for you!

Content

What are the advantages of plastic ceiling structures?

The main obvious advantage of the ceiling, made of plastic panels, can be called excellent moisture resistance. Therefore, the scope of such ceilings is extensive: they are ceilings in bathrooms or bathrooms, kitchens, balconies and loggias.

Plastic ceiling can not be flooded or flooded. In any negative situation, it will look like a brand new one. In addition, the plastic ceiling can be easily mounted and dismantled if necessary. If you decide to install a ceiling made of plastic, you need to provide criteria for choosing high-quality PVC panels and how to cover the ceiling technically.

The main criteria for selecting PVC panels

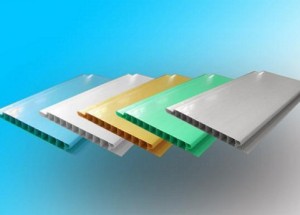

The criteria for choosing plastic panels include:

• appearance and geometric dimensions

• design features and thickness

• density and flexibility of the panel shape

• Simple and reliable joining of panels.

For finishing works, it is preferable to choose panels specially designed for this type of installation. If you plan to produce a ceiling finish, then there must be ceiling panels, if the walls are wall-made, but not the other way around. Panels for the ceiling are selected according to the area and layout of the working surface of the room. So, for placing small sizes, narrow plastic panels with a width of up to 30 cm should be preferred. When choosing a material for the ceiling from plastic panels, carefully examine each panel.

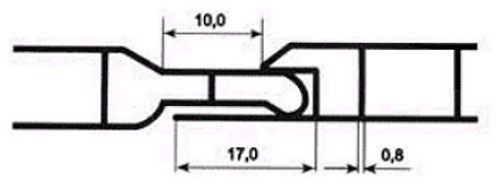

Eliminate deformed or bent edges along the edges, as well as those specimens that do not have an ideal outer surface. Examine the stiffeners of the individual panels inside. The stiffeners should not shine from within the sheet or have twisted or flattened bases. For your reference: different types of plastic panels have a certain number of ribs inside. Their number can reach 25-30 pieces for ceiling panels.

Axiom: the greater the number of stiffeners of the plastic panel, the more reliable will be the future design of the ceiling. An important criterion is the thickness of the stiffeners and the walls of the plastic panel. And, at last, check up simplicity of docking of panels. Quality plastic panels should be easy to join with each other, without leaving visible traces of assembly. When purchasing material for ceiling mounting by plastic panels yourself, take the plastic with a small margin.

The length of the finishing plastic panels varies from 2.6 to 3 m. When choosing the panels of their plastic, it is necessary to think what will be their fixing to the ceiling.

The main types of profiles and fixing the ceiling panels

profiles

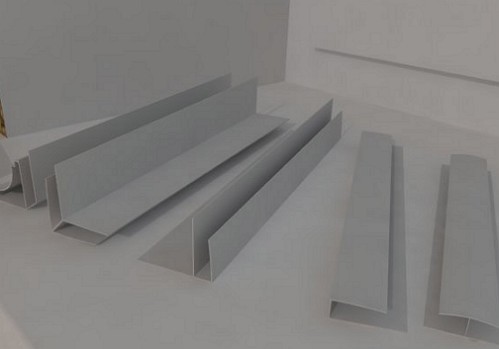

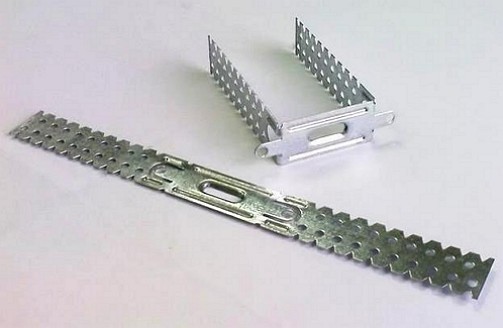

For the initial installation and fixing of plastic panels, profiles of the following types are used:

• starting

• F-Profile

• H-profile

• external and internal corner

• ceiling skirting.

The starting profile for the installation of ceiling panels is fixed around the perimeter of the room and serves to close the end elements of the panels.

F-profile during installation is designed to close the ends and when going to another plane.

H-profile is considered connecting and used to increase and increase the length of the panel sheet.

The outer and inner corners have a traditional shape and cover the ends at the respective corners.

Ceiling skirting is designed to decorate the finished ceiling from the outside.

types of fastening

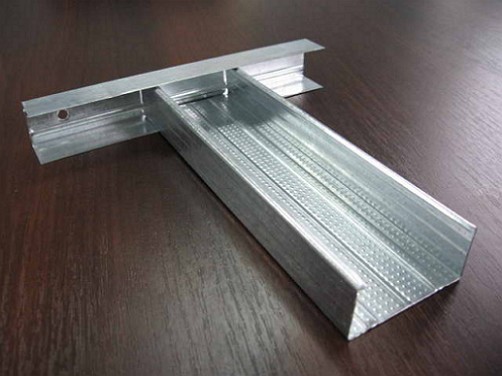

There are basic types of fixing the ceiling panels:

• on a wooden crate

• on metal profiles.

Installation of panels on the wooden crate is shown here.

The most technically difficult is the finishing of the ceiling in the bathroom with plastic panels, where the tiling is already made.

In this case, the proposed video will thoroughly show the whole process of mounting.

How to make a ceiling from plastic panels

Before assembling and attaching plastic panels to the ceiling of the kitchen, bathroom or toilet, you must prepare the panels yourself. Panels are cut using a special jigsaw according to the dimensions of the ceiling, considering the presence of pipes, boxes or other elements of the decoration of the room.

Then, a framework for fixing the panels is prepared and installed.

Mark the wall for the location of the frame: note the height of the frame and draw on the walls of the line to establish the starting profile. In doing so, it is necessary to carefully check the horizontal alignment of the marking and the correct formation of the location of the corner joints. Then the starting profile is attached to the wall using self-tapping screws.

The frame is in most cases made of wooden 4x4 cm or metal rails, which are fixed at a distance of 50 cm from each other, thus compensating for unevenness or defects in the ceiling. Mounting the structure of the frame is also carried out using self-tapping screws. After installing the framework for fixing the panels, we begin to install the first panel.

Installation of the first panel of PVC is made by installation in a profile with the subsequent fastening by self-tapping screws. The beginning of the canvas is made from the edge closest to the window.

The first panel is the most responsible, because all subsequent will be equal to the first installed panel. All subsequent panels are carefully inserted into the groove and secured to the mounting profile. In this case, it is necessary to check the density of the connection, excluding gaps.

http://www.youtube.com/watch?v=0nC6h-PoSf8

Inexpensive and beautiful ceiling made of plastic, made by own hands, will allow to save a little and will give a maximum of pleasure at installation.