For most people the steam room in the bath remains a kind of symbol of the traditions of the healing ritual and emotional uplift. Fresh design solutions have generated a lot of bathing attributes, high technologies - furnaces and units, but only the field of finishing materials remains true to nature. Listening to the tips of steamers, you can learn all the rules for the finishing of the steam room, from choosing the floor material to the bath cap.

Content

Designing of a steam bath

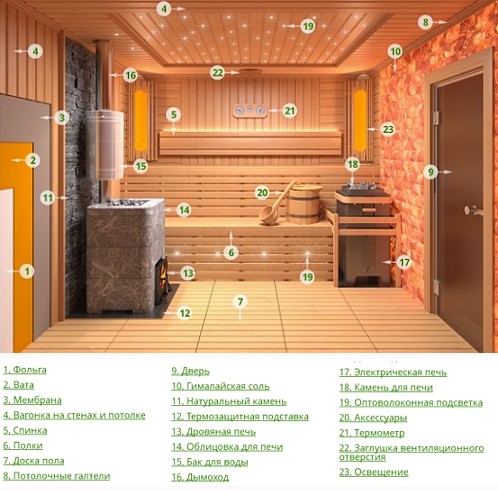

In any project, the central part of the sauna is a thermae, the installation and finishing of which involves wood lining made of prepared wood.

Bright, dry and clean room provides many factors, among which the main is the finishing of the steam room in the bath, thermal insulation and ventilation system. At the design stage and the beginning of construction it is necessary to make simple calculations of the estimated number of visitors, based on the size and area of the bath, the location of the sauna stove for the steam room and the choice of wood products.

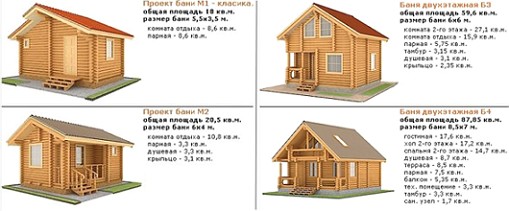

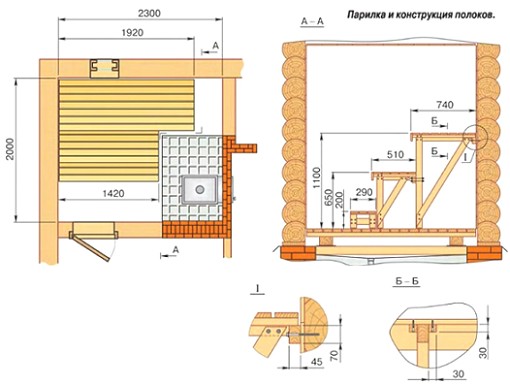

There are many standard bathhouse projects, one- and two-storeyed with a total area from 15 to 72 sq.m., in which it is planned to place rest rooms, steam rooms, showers, pools, tambours and terraces. However, in practice it is noticed that the preference is given to the steam rooms inside the bathhouse with the dimensions of the room of the steam room 2x2.4m or 3x3.5m with wooden boards on which it is possible to sit and lie and the height of ceilings is 2.5 m.

When designing and installing the steam room inside the sauna, it is necessary to provide the reliability of keeping and keeping the air heated from the oven, creating an idea of what a steam room should be. Heated air in a good steam room spreads evenly and smoothly in different directions.

How to finish the steam room

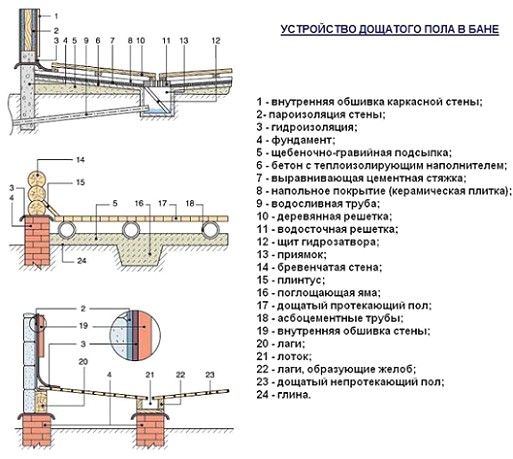

The technology of insulation involves measures for waterproofing and the sequence of work: insulation of the ceiling, walls and floor according to the same scheme, which provides a system for drawing in a therma for natural building materials for baths. Moving hot air up from the heated oven causes the choice of the thickness of the ceiling material.

According to the advice of the steamers, the finishing and warming of the steam room starts from the ceiling surface using thicker boards

(1.5 - 2 times) than for walls.

stages of insulation of the ceiling from the inside

Insulation of the ceiling from the inside is made on a prepared crate, placed around the perimeter. The ceiling of the steam room is covered with a roll insulating material with overlap joints and fixed with 5x5 blocks.

Between the bars place the insulation material and close it from the side of the room with foil and fix it with an aluminum adhesive tape. The final stage of the insulation of the ceiling is the final lining with a lining.

Helpful Tips

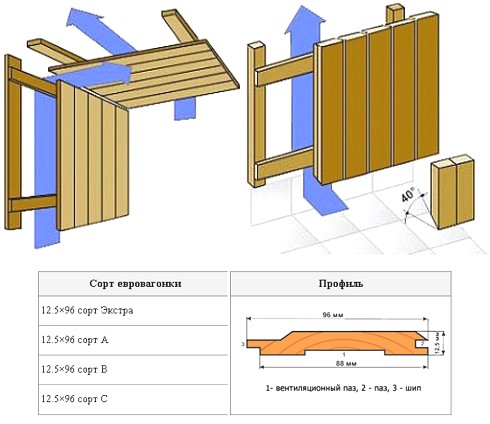

It is noticed that the paneling made of lining is a universal material, thanks to which a peculiar microclimate is created in the steam room. No qualities of fiberboard and chipboard, linoleum and plastic are able to leave the appearance of walls, ceilings and floors attractive at high temperatures. Therefore, unquestionably the lining of coniferous and deciduous trees with a tongue and groove joint is considered the main material of the finish for the steam room.

we make warming and furnish of walls

Warming and finishing the walls of the steam room is made from inside and outside the room. To make the exterior decoration of the walls of a separately standing building of a bath is possible in the form of plastering and cladding, as well as existing facade materials: siding and stone. Interior decoration of the walls of the steam room is made with the use of edging boards and lining.

For internal lining, it is allowed to use tightly fitted planed boards with a thickness of 1-1.6 cm. The optimal option is the use of a lining, which is not additionally treated with chemical preparations.

The lining is manufactured in a traditional way on the lathing with the creation of steam and waterproofing layers. As a wall heater is recommended to use mineral wool.

A heater is placed between the battens of the battens, taking into account the location of the windows and doors of the steam room. A prerequisite for finishing the steam room is observance of the rule where the door to the steam room opens. Recall, according to SanPIN, the steam room door should open outwards.

The door to the steam room is made with a raised threshold and an understated door frame in relation to the ceiling, 60 cm wide and 175 cm high, on a ball snap.

The warming of the walls of the log cabin is simpler, in comparison with the trim of the frame-panel bath and will require only the creation of a vapor barrier barrier made of foil or basalt reflective insulation.

How to properly decorate and insulate the ceiling and walls of mines wool techonikol, shown in the video.

warming and finishing of the floor

Warming of the floor of the steam room is made at the stage of creating a floor overlap, using beams 160x120 mm or 200x200 mm, logs 50x110 mm and a blackboard 25 mm. Placement of insulation 50 mm is made after two-sided waterproofing of the floor and laying of the floorboard, impregnated with 2 passes antiseptic and fire retardant, topped with varnish.

The height of the log is recommended to be chosen in accordance with the thickness of the insulation, with attention being switched to the correct setting of the log with a pitch of 500 mm and fixing to the ceiling.

The technology of finishing the floor in the therma is simple and consists in laying the prepared boards closely with the subsequent fastening of the screws.

As a finishing warmth will not prevent to make a wooden grate on the floor and build leaking flooring.

Installation, warming and finishing of the floor in the steam room will be associated with the placement and installation of a sauna oven and the creation of the design of the shelves.

The parquet is obligatory equipped with benches and shelves, one-tier and corner, located at 2-3 levels along the perimeter and underlined with decorative design.

Helpful Tips

Decorative design of the steam room and selection accessories for the bath, work on the installation of water supply, lighting and shelves is no less significant than the process of warming and finishing.