Fences and wickets from the metal profile are very popular. This is a relatively inexpensive, durable and durable material. But no matter how reliable the fence, if there is no good castle on the gate, then there can not be any security of speech. Choosing a lock for a gate from a metal profile, it is necessary to consider many nuances - strength, reliability, type of the locking mechanism, etc. What types of locks are suitable for installation on the wicket, how to install the lock on the gate - all of these issues we will look in more detail below.

Content

Types of locks for installation on a gate

hinged or barn chateau

Used most often in the garden or garden areas. The hosts set such locks in case they are not afraid of penetration of uninvited guests. Simply put, such a lock is placed on the gate where, to put it crudely, there is really nothing to take.

rack and pinion lock

Still quite a type of locking mechanisms was found everywhere, now it is almost not used. This construction consists of the actual bolt, which freely moves along the loops. The loops themselves are welded or screwed to the gate or fence. The drawback of such a lock is that you can open and close it only from the inside. Yes, and to crack the lock is not difficult - just cut it with a hacksaw for metal. We do not recommend constipation of this type, because of its unreliability and impracticality.

mortise lock

It is already clear from the title that locks of this type are installed inside the wicket door, which makes it very difficult to crack. However, it is not possible to install a mortise lock on all wickets, and most of them are not particularly reliable - if a thief very much wants to penetrate your site, it will easily open the mortise lock with a master key.

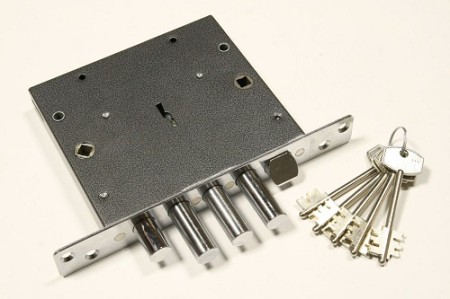

consignment lock

The lock for a wicket of this type is reliable, it is difficult to crack. The overhead lock is installed in a fairly short time using a welding machine and a drill. The drawback of this type of locks is that it can simply be broken with the help of an ax, a "crowbar" or a small crowbar.

electromechanical lock

Such locks are also called code locks. They are much more reliable than electromagnetic locks. The electromechanical lock represents the instrument panel and a shutter mechanism. To open or close the lock, you need to type the code on the panel. This is a very reliable system - if there is a need, then the lock opening code can be changed as much as desired. The drawbacks of this type of locking mechanisms include the constant need for electricity. Of course, modern manufacturers equip electromechanical locks with rechargeable batteries, but a battery for that and a battery that can sit down at the most inopportune moment. Replace the battery only from the inside. The latest models of electromechanical locks provide for continuous recharging of the battery.

Hack such a lock is almost unreal, unless only with the availability of expensive and rare equipment to find the appropriate code. There is a kind of electromechanical lock, in which instead of the code an electric signal is used from pressing the button.

electromagnetic lock

This locking mechanism is known to all residents of cities, since it is most often installed on the door of entrances. Opens such a lock with a magnetic key. Each mechanism is tuned to the magnetic field of the key. When such a key is brought to a special notch on the pad, it opens. There were such castles about 10 years ago. At that time they were considered extremely reliable. But modern "craftsmen" have long learned using special equipment to easily select the necessary electromagnetic combination and make keys.

radio wave lock

The work of this mechanism is similar in its principle to car alarm. Among all the above types is considered the most reliable, as it is almost impossible to hack. This requires profound professional knowledge in radio engineering plus very expensive equipment. True, it is impossible to install such a lock on their own, they are put exclusively under the order, the installation takes enough time and requires professional knowledge and skills.

As you can see, there are a lot of types of locks, and they stand in different ways, but we will consider installing two types of locks on the wicket from the corrugated board - mortise and overhead. Important point: the locks, which are intended for installation on the wicket, are distinguished by a narrower bar and a small distance from the bar to the center of the locking mechanism. In general, almost all locks for wickets are designed specifically for mounting on metal profiles.

Installing an overhead lock

So, there is a ready-made wicket, sheathed with corrugated board and hung on canopies.

You will need:

- Welding machine.

- Sheet of three millimeters steel.

- Drill.

- Bulgarian with a circle of metal.

- A stitch and a square.

Install the lock on the wicket from the corrugated board is quite simple. The work is simplified even more if we weld a transverse crossbar on the skeleton frame at a height of approximately 90 cm from the ground. The lock must be applied from the inside so that one of the holes intended for fastening coincides with the horizontal jumper, and the handle and core are lower and higher than the jumper. Mark all the necessary holes in the frame, as well as a notch for the deadbolt.

If the column near the wicket is narrow or made of a round pipe, it will have to weld a piece of corner or plate, to mount the mating part of the lock. We drill holes for the fasteners in the proflist for the key and handle. Holes in the profiled sheet are drilled along the contour and aligned with a round or flat file. Similarly, make a groove for the bolt in the pole. Now it remains only to fix the lock itself, install the core, handles and lining on both sides.

In the process of installing an overhead lock, this problem often arises: the corrugated sheet prevents the nuts from being screwed onto the threads of the bolts from the other side. From this situation, you can get out as follows: if the corrugated board was fixed with screws, you can partially loosen them or unscrew them completely, and then fix the sheet back. If the sheet is fastened with rivets, then metal screws can be used to secure the lock. In this case, of course, drilling holes for fastenings is not necessary.

Install mortise lock

Often the frame of the wicket is made of a thin pipe, section of about 20x40. In this case, to install the lock on the gate with your own hands, you have to cook under the lock case a box of steel sheet. The dimensions of the box should be such as to leave small side gaps between the body and the walls of the lock. The steel for the box must also be labeled with a thickness of at least three millimeters. From the end side of the wicket we make a groove for the bolt and drill holes for the fixing screws. It is very desirable that the holes are outside the box for the lock, otherwise there will again be difficulties with the nuts.

Further in the box on both sides, it is necessary to make grooves for the key or the whole core. The answer part of the locking mechanism is fixed to the post. After that, it remains only to assemble the lock. This is the easiest way to install a mortise lock on a wicket door. Accurate it can hardly be called, in addition, the lock with such an installation is almost completely open for snow and rain.

Consider the most, so to speak, modern and civilized version of the lock on the gate. On sale already for a long time already there are mortise locks, specially intended for installation on a wicket from proflista. They are narrow and perfectly mounted on a profiled pipe with a width of 40x50 mm. Install it fairly simply. After the marking is ready, in the end part of the wicket choose the groove under the case of the lock. We make with the help of the grinder two vertical rubbers and one on the diagonal - the resulting triangles are gently curved outwards and cut off. Drill holes for fixing screws and core.

To accurately mark the place for the mating part of the lock, you can use putty, toothpaste or any well-colored substance. We smear it with a bolt, then we close the gate and turn the key - on the post there will be a clear trace from the tongue - in this place we make a groove. After all the holes are ready, you just need to secure the lock with screws.

Choice and installation of the castle: a few tips

The lock for the wicket must meet certain requirements. Since the mechanism will work on the street, it must be resistant to corrosion, not to be afraid of dust and moisture. These locks are fully compliant with locks of the lever type.

In such locks, the key displaces curly plates inside the lock. But do not delude yourself - the water that got inside the mechanism and freezes there will disable any lock, regardless of its type. For this reason, it is recommended to choose a lock for the wicket, which opens from the inside without using a key.

The locking mechanism for the wicket from the corrugated board should be as compact as possible. A massive lock, mounted on thin profile pipes, simply will not work. The lock on the wicket must be installed so that there are no excess slots and slots in which moisture will enter. Before you buy and install the lock, check the operating status of each key that is attached to it. The lock should work smoothly and without interference. If the key turns in the lock with difficulty, such a mechanism should not be bought.

There are a lot of locks, and what kind of lock to put on the gate is up to you. We hope that the material given in this article will help to make the right choice.