The roof is a very important element, protecting the interior of the building from the effects of the environment. If the roof of the house has deteriorated from the deterioration, it has been damaged by a strong wind or as a result of falling trees, then the life for the inhabitants of such a dwelling becomes simply unbearable: in the winter, the building is cold, there is a leak and in the premises from high humidity the wallpaper falls, furniture collapses, molds appear on the walls . This is a signal to the fact that it's time to take measures to restore the integrity of the roof.

Building the roof of the house

The main purpose of the roof is to protect the building from atmospheric precipitation. If the roof of the house has a complex shape, and still covered with beautiful roofing materials, then in addition to the protective function, it also plays an aesthetic function. For a good modern home, it is very important to combine two functions: practicality and beauty.

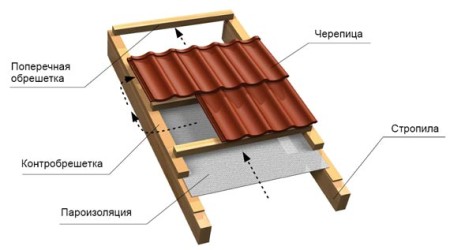

The roof of the house can have the following elements:

- rafter system;

- crate;

- vapor barrier;

- heat insulation;

- waterproofing;

- roof;

- dormer window;

- penetration (in case of passage through the roof of chimneys and ventilation);

- additional elements: rainwater system, cornice, snow holder, cable heating system, etc.

As you can see, the roof of the building consists of layers that protect the attic space from cold and moisture and constitute the so-called roofing "pie".

The rafter system is the skeleton of the roof and rests on the walls of the house; The load from the roof is evenly distributed on it and transferred to the walls. It is the rafter system that determines the shape of the roof. There are two main types of roofs: flat and pitched.

Flat roofs are made without a slope or with a slight slope and are most often used in construction in southern regions with low amounts of precipitation in the form of snow, since flat roofs will not move independently under the influence of their weight. Such roofs have a low cost, but they require special attention during operation. Flat roofs must be constantly serviced: at least 1-2 times a year to clean them from the leaves, and in case of snowfall, do not allow the accumulation of snow on the roof. When designing flat roofs in regions with large amounts of snow, considerable additional weight should be taken into account, and therefore sawn timber of increased thickness should be used. With the accumulation of snow on the roof, the load on the walls increases, so they must also be designed for this extra weight.

Pitched roofs, in contrast to flat ones, are more complex and heavy, require a lot of materials, they have a slope of the surface, however, snow and leaves are less likely to accumulate on the roof, they are removed from the surface by gravity. By the number of skates and the methods of their interface, the roofs can be divided into several types. It can be one-, two-, four-slope (hip), mansard, multi-snap, dome and some other types of roofs. Less common are the hipped roofs, which usually end in towers. In recent years, private house owners have increasingly preferred roofs of complex shapes. This is due to the desire to emphasize the individuality of the house, as well as the desire to rationally use the under-roof space. Increasingly, the choice of roofing for a private home is already creativity.

Roof insulation

To keep heat in the space under the roof, or to prevent it from leaking from the upper floor through the floor, heat insulation is applied. For this purpose, a wide variety of materials can be used: mineral wool, glass wool, expanded polystyrene, extruded polystyrene foam and some others. The thermal insulation layer must have high insulating properties, be durable, light, environmentally safe and non-flammable.

Mineral wool is a relatively inexpensive material, available in the form of rolls or slabs, has durability, high fire resistance, environmental safety, excellent thermal insulation properties. Mineral wool can be made from molten rock or metallurgical slag. One should only bear in mind that cotton wool, obtained from slags, has a shorter service life.

Glass wool is similar to mineral wool and therefore has the same properties, however, glass industry waste and materials from which glass is made are used as raw materials. A disadvantage of glass wool is the high friability of glass fibers that damage the skin, can get into the eyes and lungs, therefore work should be performed only in special clothing with mandatory use of protective glasses and a respirator. Glass wool is produced in the form of mats, plates and coils.

Polyfoam is a foamed mass, has a low weight, a low heat transfer coefficient, a relatively small price, is easily cut. Styrofoam is safe for humans, with the addition of fire retardants it does not support combustion, but it burns under the influence of open fire with the emission of harmful substances. The service life of foam plastic is less than that of mineral wool, in dachas and in country houses, styrofoam is often used by rodents as their habitats.

Styrofoam and expanded polystyrene are produced from the same raw material, however, various technological processes during manufacturing allowed to obtain a material that differs in its physical properties. Extruded polystyrene foam is expanded polystyrene foam and has a number of advantages: very low thermal conductivity, resistance to chemicals, significant water and vapor tightness, resistance to mold, environmental friendliness. Due to the small thermal conductivity, the insulation layer will be more subtle. To disadvantages is the higher cost in comparison with other heat-insulating materials.

Polyurethane foam is applied to the surface by spraying, with the characteristic feature being durability, absence of seams, monolithic structure, the possibility of performing thermal insulation of the roof of any shape, good sound insulation. Polyurethane foam with high density, in addition to insulation, performs the function of waterproofing. The disadvantages are the high price, the need for special equipment and the complexity of the process of applying the insulation layer.

Steam and waterproofing roofing materials

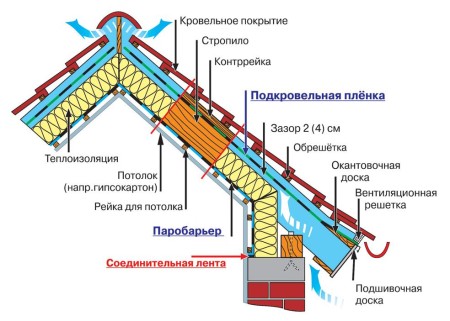

Such widely used materials as mineral wool or fiberglass have a fibrous structure, which means that their thermal insulation properties deteriorate very sharply if there is moisture inside the material. It can get into the heat-insulating layer from above through the roof in the form of precipitation or from below in the form of steam lifting from the building's premises. To prevent penetration of moisture in the first case is equipped with waterproofing, and in the second - a vapor barrier.

The films of steam and waterproofing are outwardly similar, but they perform different functions. The vapor barrier film does not pass moisture in any direction, including steam, and the waterproofing film is manufactured by membrane technology and is a multilayered material with microscopic pores, through which water vapor penetrates, but does not infiltrate water in the liquid state. Drops of water will roll down from the sloping roof or simply lie on a horizontal surface.

Steam insulation on the roof is placed from the bottom of the heater, its task - to reduce the amount of steam that penetrates into the heater. The waterproofing is placed on top of the heater and must prevent water from getting into the water and allow the steam to escape, which is still in the heater.

To increase strength, the vapor barrier film can have a mesh reinforcement or include an aluminum layer for better heat preservation. Some manufacturers apply a sticky layer for bonding individual strips.

When building or repairing a house, ordinary polyethylene film, which has a low price, is often used as insulation. However, it should be borne in mind that polyethylene has a very short life, low strength, is quickly destroyed under the influence of various environmental factors and therefore can not compete with specialized vapor barrier and waterproofing materials.

Films, depending on the manufacturer, can differ from each other in density, thickness, and strength. Waterproofing materials are characterized by the coefficient of vapor permeability: the higher it is, the better. This means that the film is able to pass through a larger amount of steam. The main parameters of the film also include resistance to ultraviolet radiation, strength characteristics for transverse and longitudinal rupture and moisture resistance, i.e. the amount of water that the film can withstand.

Types of Roofing Materials for Roofs

Selection of roofing material is a responsible task. To the roof are high demands: reliability, durability and manufacturability. Roofing greatly affects the perception of the appearance of the entire building. Covering the roof can be divided into the following types: soft and hard.

Several types of soft roofing are made, but almost all of them have the same elements: fiberglass and bitumen. The soft roof has a resistance to water and fire, it absorbs sound well, so during the rain the sound of falling drops is not heard. Under the soft roof is understood as a detachment of materials that belong to the economy class and are divided into roll and piece. The roofing is covered with ruberoid, euroruberoid, glass ruberoid. The rule applies to roll materials: the smaller the angle of the roof slope, the more layers it is necessary to stack.

The soft piece roof is made of the same raw materials, but it is made in small sheets and laid on the roof layer by layer from the bottom up so that each layer overlaps each other, thereby creating a waterproof coating. Elements of such a roof are called shingles.

To the hard roof are a large number of materials: tiles, metal, corrugated board, asbestos cement slate, Euroshaft and others

The tile is environmentally friendly material, fireproof, resistant to environmental influences, but has a high cost, very high weight and is difficult to install.

Metal tile is durable, possesses b aboutlarger sizes and smaller mass, the laying of the coating is quite simple. But the metal tile also has disadvantages: it has increased noise and a high probability of damage by a strong wind due to its small mass, easily corrodes in case of damage to the protective coating.

Profiled flooring is used in a variety of types of construction, including roofing. It is made of galvanized sheet metal by rolling, with the sheet being given a certain profile and can be coated with a polymer coating. Profiled sheeting is characterized by high strength, durability, environmental safety, but it is more expensive, noisy and rusted when the protective coating is broken.

Asbestos cement slate is a material in the form of corrugated sheets, characterized by durability, relatively low price, fire safety, low noise. To drawbacks can be attributed great weight and harmfulness to humans, since it contains asbestos. In connection with the latter, ordinary slate is almost replaced by more modern environmentally friendly and light materials.

Evroshifer is a modern material made of cellulose fibers, fiberglass, impregnated with resins, bitumen and dyes. It has an affordable price, low weight and sufficient strength, is environmentally safe, does not lend itself to rotting, chemically stable, very simple to install, not noisy, does not support combustion, although it burns in open fire. The second name of this material is ondulin, which comes from the name of a French company that started producing this building material. Evroshifer over time burns, but it does not lose its properties and if desired, the burnt material can be painted, giving it the original look. To the negative qualities of the Euroschlip is its relatively short life - up to 25 years. Nevertheless, summing up all its advantages and disadvantages, the Euroshare is considered to be very good material and therefore received recognition and wide distribution in our country.

Rigid roofing is a good option for a roof that will last for many years with faith and truth. This coating does not require frequent repairs and looks beautiful.

Roof replacement, its necessity

Work on the arrangement of the roof must be preceded by a thorough examination both outside and inside. If the old covering is not removed during the repair, the total weight of the roof will increase due to additional roofing, thermal insulation and roofing material, so the roof rafter system must withstand the increased load. The old roof will have to be dismantled if, during the inspection, it becomes clear that the main structural components of the structure are damaged, the replacement of which is impossible without disassembly.

When dismantling the old roof, the question arises, is it necessary to produce it before installing the old one? When carrying out repairs, it is best to disassemble the old roof and put a new one in its place, having made the insulation with modern materials. However, for various reasons, it is not always possible to dismantle the old roof. This may be due to the time limit for repair, the greater weight of the coating to be removed, the inability to dispose of the old roof, or for any other reason.

If the construction of a new house, depending on their preferences and financial possibilities, the owner can choose any type of roof and any materials, then when repairing an old house, he has to take into account the peculiarities of this building. It is necessary to know that the rafter system determines the shape of the roof and when the roof is replaced, both it and the corners of the ramp do not change. Before laying a new roof over the old one, the roof crate must be installed. Variants of used materials for the roof can be very different.

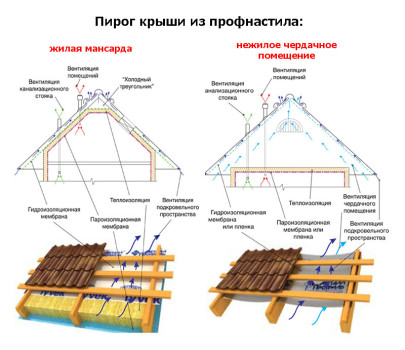

If the attic space is not intended for habitation, it can be made cold and ventilated, but in this case the insulation of the floor must be made. If an attic is required to equip a warm residential attic room, then the roof itself must be insulated, for which a multi-layer roofing "cake" is arranged.

We do the crate, insulation and roofing on the old roof, detailed instructions

the order of installing a new roof over the old without insulation, useful tips

Since during the repair the total weight of the roof increases, it is recommended to use such lightweight materials as metal roofing, corrugated board or Euroshield as the roofing. Due to their light weight, these materials are very easy to install and, if necessary, one person can cope with work. For cutting metal and corrugated board, an electric power tool is required, and the Euroshape sheets are easily sawed with an ordinary wood saw across the wave, along the waves - cut with a construction knife. To the teeth of the hack-saw not get clogged, they are damped with ordinary water.

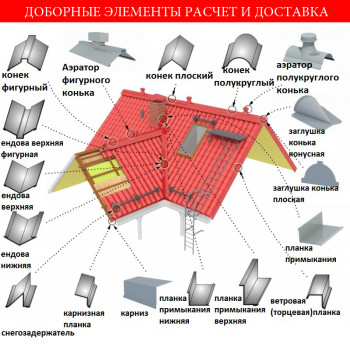

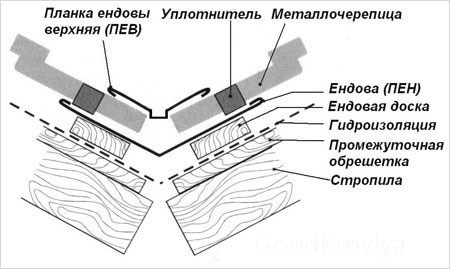

Repair of the roof is much simplified and materials are saved if a cold attic is planned to be used or the old layer of insulation is supposed to be used. For such a roof you need a wooden beam of 50x50 mm, roofing material and additional elements of the roof. The composition of the latter depending on the complexity of the roof may include vents, skates, skate caps, valley, wind braces, etc., which are intended for ventilation, to protect the roof fractures, places of contiguity of the roof to the walls and pipes from the effects of rainfall and falling foliage and dust. It is fair to note that, compared with the relatively low cost of such roofing as ondulin, cost of complete fixing elements to it is rather high, so often used cheaper skates, valleys and other elements made of galvanized metal coated.

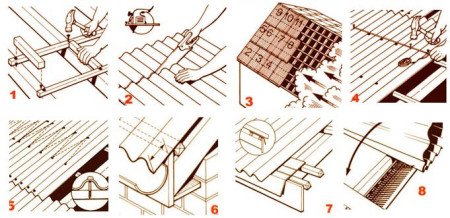

Before repair, the roof must be cleaned of old leaves, twigs, dirt, pieces of old roof, etc. If the old roof was made of roofing material, then the boards and slats with which it was attached to the surface are also dismantled. An obligatory condition for the crate along the old roof is the installation of a cross crate. The scheme of the battens on the old roof provides for installation first of all vertical, and then on top of it - a horizontal crate. According to the size of the roof, vertical and horizontal beams are marked and cut, and in horizontal it is necessary to make drunk by the size of the protruding part of the old skate. To ensure that the screws are firmly attached to the old crate, which is under the slate, the beam and slate are pre-drilled. Self-tapping screws should be of such length that they are securely screwed into the old crate or rafters. The bars are attached to the lower wave of the old slate. First, the outer boards are installed, a rope is fastened to the lower part, along which the lower edge of all intermediate bars will be aligned. Vertical bars are stuffed on the slope of the roof with a pitch of about 60 cm. If the vertical beams falls on a place overlapping two sheets of old slate, in order to obtain a flat surface, the top timber is drunk in Slate thickness for horizontal mounting batten.

After fixing all the vertical bars on top of them in a step of 61 cm are installed horizontal beams of the crate. At all points of intersection of vertical and horizontal beams, they should be fastened together with self-tapping screws of at least 70 mm length. Outside, at the ends of the roof, a bar is stuffed, to which, at the end of the work, the wind bar or windboard will be fixed.

The next stage is the marking and installation of the roofing. Laying of the roof should begin to be carried out from the side into which the prevailing winds blow in this region. For example, if there is a north wind more often, then the laying starts on the south side. The first lower stacked sheets, so their alignment recommended pull rope so that the lower edge of the hanging roof 7 cm. The sheets must be stacked evroshifer lapped and nailed to the top of the wave. There is a norm for the use of nails for fixing ondulin sheets - according to the attached instructions, there must be 20 pieces per sheet. Hats nails for undulia are large and strongly stand out on the roof, so their location is recommended to carefully mark with a ruler and hammer nails through the wave strictly in staggered order. Nails must be clogged, making sure that the sheets lie flat.

The overlap of the ondulin sheets should be one wave, after the completion of the row the last sheet of coating is cut off along the edge of the roof. To avoid the junction of four sheets, the first sheet to be used in the next row should be cut in half. The sheet should be vertically spaced at least 10-15 cm.

If the roof has a complex shape and there are furnace and vent pipes, then all the angular joints of the roof elements and the place where the roof joins the pipes are equipped with additional elements. At the outlet of the pipe, additional beams are attached to the lower row of bars to fix the roof, and the roofing sheets are cut in such a way that they fit snugly against the surface of the pipe. After covering both sides of the roof, a skate is mounted, which is fastened with nails to each wave of sheets underneath. Installation of the ridge is carried out with an overlap of at least 10 cm and begins with the same side with which the sheets of roofing.

At the end are attached wind braces or wind boards, cornice boards, which protect the attic space from the wind, favor the maintenance temperature, do not allow birds to nest under the roof, and give it a finished look.

A detailed description of the works can be seen on the video.

the order of installing a new roof over the old one with insulation, useful tips

It is somewhat more difficult to make a ceiling with thermal insulation. In this case, in addition to a wooden beam of 50x50 mm, roofing material and additional roofing elements, materials will also be needed to create a roofing "pie": heat-insulating, waterproofing and vapor barrier films.

The order of work is similar to the installation of a roof without insulation, with the difference that after the fastening on the roof of the lower vertical beams, a vapor barrier film is rolled over them. As well as roofing sheets, the vapor barrier starts to be mounted from the bottom of the roof from the side opposite to the direction of the prevailing winds, the lower section of the panel being at the level of the wall. The film is attached to the beams using a construction stapler with a pitch between the staples of 150-200 mm. The overlap of the panels is not less than 10 cm, and, the more sloping the roof, the greater the overlap, the joints of the panels are glued with an adhesive mounting tape. Then, a horizontal crate is installed over the vertical parquet with steam protection in the same order as in the previous description.

Thermal insulation is laid from the ridge between the horizontal bars, and in order for it to be securely fixed, the width of the insulation strip should be 1 cm larger than the distance between the beams. It is not attached to anything, but it is held only at the expense of a larger size. The thermal insulation layer should lie flat, close to the beams and the adjacent insulation piece, otherwise heat leakage will occur in these places.

To protect the heat-insulating layer from moisture, a waterproofing foil overlaps with the adjacent panel. The film is attached to the crate in the same way as the vapor barrier layer.

When performing roof insulation work, special attention should be paid to such problem areas as stove and ventilation pipes, dormer windows, etc., as they are the places of leaks. In addition, the water vapor produced in the room has a high drooping ability and in such places it is most likely that it penetrates into the heat-insulating layer with insufficient tightness, which ultimately results in a loss of heat.

After the installation of the thermal insulation is completed, the roofing material is laid. The order of its installation on the insulated roof does not differ from the order of work with the insulated roof.

A detailed description of the works can be seen on the video.

Correctly executed work on the installation of a new roof will transform the old house, save its inhabitants from cold and moisture and even help increase the living space by rebuilding a cold attic in a warm attic.