In order to produce linoleum linings with your own hands, you do not need to have a certain construction specialty. This is not a difficult matter at all, and with a certain amount of patience and diligence, you will necessarily succeed. And our article will help you in this.

Content

Preparatory works for laying linoleum

First you need to prepare what we need in the process of work. This, of course, directly, the linoleum itself, as well as the tools necessary for work:

- Very sharp knife (for cutting linoleum);

- Metal meter line;

- Set of spatulas;

- Rubber hammer (for straightening or, in another way, percussion, linoleum).

A week before the beginning of the laying of linoleum on the floor, it must first be unwound from a roll and cut to size, and then put the finished cloth face down. If after a week or two, the waves on the linoleum do not go away, and it does not completely level out, then it is ironed with a bag full of hot sand.

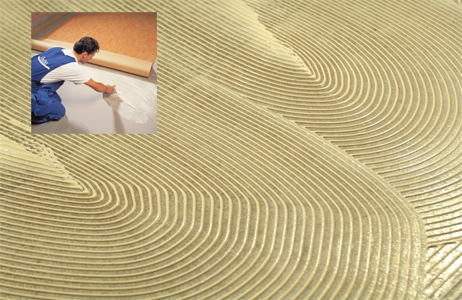

So, the linoleum is leveled, soiled and ready for packing. It's time to decide which glue to choose for linoleum. No special difference in the types of glue for linoleum. You can choose the one that, in your opinion, is most suitable for you. Only take into account the fact that for various glue mastics and all kinds of dispersion adhesives (without bitumen in the composition) linoleum is laid immediately after their application. If the mastic or glue for linoleum are made on the basis of bitumen, then linoleum should be laid after their application no earlier than in fifteen minutes. That is, they have applied glue (or mastic) to the floor and directly to the linoleum on the back and wait for a while, then start to glue.

Paul, before he will be laid linoleum, be sure to align. In the case when linoleum is placed on concrete, the floor is leveled with a screed from a solution of cement and sand, and left to dry for a day. When the screed becomes firm, the alignment preparatory work is considered finished.

How to properly lay linoleum on concrete

If you are not sure that the walls and corners in the room where you are going to lay the linoleum, even, then it's best to start laying it from the middle, and not from the wall.

We pick up a notched trowel and apply with its help a binder to the surface of the rough floor, starting from the middle of the room. On the back side of the linoleum we also apply a thin layer of glue.

In those places where there will be butt seams, glue (or mastic) directly on the floor itself is not applied, leaving these places not overshadowed about 12 cm in size. When you lay the linoleum in the area of joining the floor with the wall, mastic or glue will be applied in mandatory order. Adhesive is applied to the thickness that is recommended by the manufacturer on the package, depending on the marking of the linoleum to be laid.

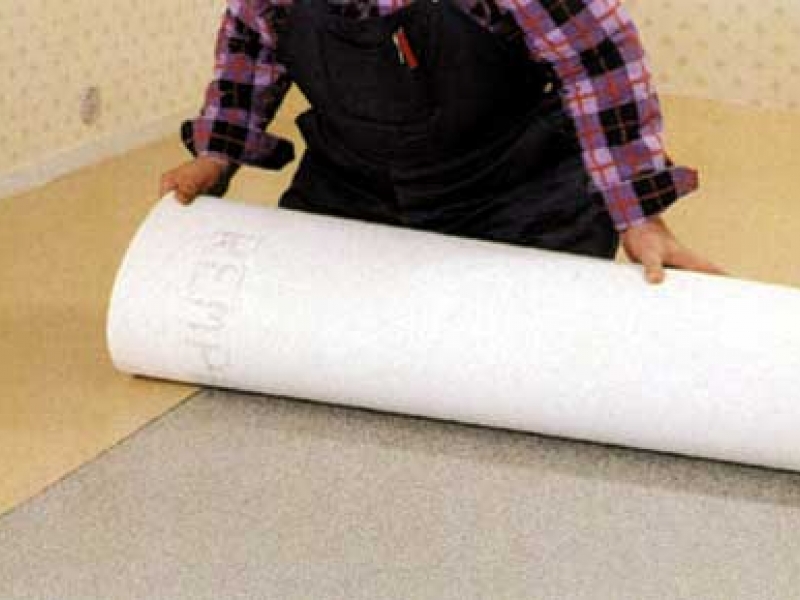

Placed linoleum on the floor rolls tightly into a roll to half the room. On the free half of the floor we apply glue or mastic. When you roll the rolls backwards - forward, gradually glue the linoleum, rolling it to the base, thus moving from the center of the room.

The air from under the linoleum to be glued must be thrown out, with effort and carefully traversed on its surface with a rubber roller or simply an ordinary clean soft cloth to avoid the appearance of laying defects, as well as waves due to the fact that the linoleum can begin to partially peel off. Defects and waves also occur due to the lack of gaps in the field of joining the walls and floor, if not completely glued linoleum in conditions of a possible increase in temperature in the apartment will begin to expand.

If we do not want seams to be at least to some extent visible, but they would be strong enough, then we can use cold welding. Lay sheets of linoleum at the joints paste with a wide paint tape and carefully fix it. Then take a sharp knife and deepen its blade into the seam between the sheets of linoleum, thus cutting along the previously pasted paint tape. In this formed incision, a nozzle of a tube of special glue intended for such cold welding is introduced, so the glue is dosed in between linoleum sheets that are tightly pressed against each other. After some time, indicated by the manufacturer of the glue on the packing of the tube, the paint tape is removed.

The work is completed by pruning excess material off the walls and installing it, as well as fixing the skirting board.

How to put linoleum on the wooden floor

From the floor, you must remove all irregularities. If during the inspection it is found that most of the boards are worn out, then it is better to change the most unfit ones to new ones, or to tighten them with screws to the lags, tightening them tight. All cracks and irregularities should be carefully puttied. On the joints of the boards it would be good to go through the plane.

It is best for the future linoleum to lay plywood sheets or OSB slabs, fixing them with screws.

Another method of leveling the wooden floor is its screed. It is best to purchase a composition in the specialized store for leveling wooden floors. This will help to conduct such work very quickly and as efficiently as possible. Having fixed the loosened boards, they are screwed to the lags and the gap between them is puttied. Then, after the plaster has completely dried, the floor is thoroughly cleaned and a self-leveling screed is applied no more than 10 mm in thickness.

If we want the linoleum to last as long as possible, then it must be placed on the glue or special glue mastic. How to do it, we were described above (the way of gluing is the same as on the concrete floor). Also, you can find out more about this by watching the video below.

In small rooms, with an area of up to twenty squares, linoleum can not be glued, for this it is perfectly permissible to use double-sided adhesive tape (adhesive tape). So the work goes much faster and easier, and when dismantling, there are no significant problems at all.

Two-sided scotch is laid out along the perimeter of the room where you plan to lay linoleum, without removing the protective film from its upper part. Linoleum is rolled into a roll and gradually it is laid out on the floor, a protective film is removed from the tape, the roll is untwisted and glued to double-sided scotch. If the width of the linoleum is small, and does not cover the entire room, then stack two rolls of linoleum immediately. The gap formed between sheets of linoleum is welded either by cold or hot welding.

At the end of the work, fix the floor skirting boards. But not at once, the same day, but after some time.

Next, we provide you with a video instruction on laying linoleum with your own hands, after seeing which, you can once again make sure that this is a simple and very interesting work, the results of which, if your relationship is faithful, will please both you and your family for many years.