OSB plates in domestic construction began to be used relatively recently. Nevertheless, they were able to gain popularity quickly enough. First of all due to its high quality characteristics and attractive appearance. A OSB plate made of natural wood shavings is manufactured, the technology of its manufacture allows to give the plate extreme strength and resistance to moisture, and the surface, which is varnished, especially if it has been subjected to grinding, looks interesting enough. You can use OSB slabs as finishing wall materials or roofing materials, they can be laid on the floor, you can even build small houses from them. Let's note, it is not necessary to consider modern plates OSB as a kind of well-known material called particleboard, it is completely wrong.

Content

What are OSB plates (OSB)

Both of these names refer to the same material. The OSB plate has technical characteristics that allow it to compete very successfully:

as a structural material with wood-laminated plastic and plywood,

as a finishing - with plasterboard and gipsovoloknistym sheet, MDF, fiberboard and chipboard.

According to the design, it is multilayered, 3 - 4 layers, its sheets consist of very thin long chips, glued together with various water resistant resins, artificial wax and boric acid, at high temperature and under high pressure. In different layers of the plate the chips are oriented differently: in the inner - transversely, in the outer - longitudinally.

As a raw material for the production of OSB panels, chips or chips of pine are usually used, sometimes aspen. Dimensions used in the production of chips:

- the length of the fragment is from 7.5 to 15 cm,

- width - from 1 to 1.2 cm,

- thickness - from 0,5 to 0,8 mm.

From waste, i.e. smaller pieces of wood produce plates of a different type - DSTP.

How OSB plates are marked

Almost all manufacturers of plates produce the following types:

- OSB4, the most durable, allowing use in structures with increased mechanical loads and high humidity,

- OSB3, expensive, are designed for operation in conditions with increased mechanical loads and humidity,

- OSB2, recommended for the construction of load-bearing structures in rooms with a relatively low level of humidity,

- OSB1, characterized by lower strength and resistance to moisture.

Also the plates can be:

- lacquered, on the front surface of which a layer of varnish is applied,

- laminated, laminated, used for the multiple construction of formwork for pouring concrete,

- grooved, i.e. They have the ends processed on the principle of the comb-groove from two or four sides.

OSB-plate - characteristics and properties

- A rather long chip is used to make the material, which ensures its high retention capacity. The advantage obtained from this property is that it is possible to fasten the panels at the very edge, clogged at a distance of only 0.6 cm from the edge of the nail does not lead to the appearance of chips.

- High processability of the material: it can be processed with any joiner's tools, sawing and cutting, sanding and scraping, nailing and drilling holes in it.

- To glue the boards, you can use ordinary joiner glue on a synthetic basis, the preparation for gluing will be the sandpaper. The material can be painted if desired, and when using it as an external finish it is recommended to use special paint and varnish to protect against moisture.

- The average density of the material is about 640 kg per cubic meter, but it can vary within small limits.

- Since OSB is a material used in the production of wood components, some reaction to the effect of high humidity is still noted. But at the same OSB panels comply with American standards, implying no changes in material parameters at a temperature of +20 C and humidity of about 65%. Such parameters are typical for internal structures. The higher resistance to the influence of the external environment is characterized by OSB3 and 4.

- Standard OSB-slab dimensions are as follows: grooved - 2440x1220, 2450x590, 2440x590, 2500x1250 mm, conventional, with a flat edge - 2440x1220, 2500x1250 mm.

- Depending on the type of panels, the thickness can range from 22 to 9 mm.

- Deliveries of the material are made by packages containing 35-10 sheets.

- The result of repeated studies showed that the material has fire resistance to a certain extent, about the same as plywood. It can be used for external cladding of structures, but it is recommended that the frame space be filled with non-combustible mineral heaters, for example - with mineral wool.

Disadvantages and advantages of OSB

If we talk about the disadvantages of the OSB, then we must admit that it is rather difficult to find them. First of all, it is the necessity of strict observance of precautionary measures and rules for the performance of works from this material. For example, when handling slabs, a mask or respirator should be worn - it is not advisable that resin dust gets into the respiratory tract.

Advantages the material has a much larger amount:

- the structure of the material is fairly uniform, which prevents the possibility of its stratification or splitting, the penetration of moisture into the interior, deformation even under prolonged exposure to a moist medium,

- it is not characterized by the presence of cracks and internal voids, defects from fallen knots that occur in natural wood material,

- good retention of fasteners,

- simple and easy processing,

- simplified installation due to the possibility of a grooved connection,

- environmental friendliness, no propensity to release toxic substances, the material belongs to the class E1,

- increased resistance to mechanical stresses and abrupt changes in the temperature regime, while resistance to loads is the same in different parts of the surface, to forces applied in different directions,

- high moisture resistance: after being in the water during the day, the percentage of swelling of the material is about 20%, while destruction does not occur, and strength is maintained,

- a small specific weight and a small thickness of the material, flexibility and elasticity that do not affect its strength properties,

- the ability of buildings to withstand earthquakes,

- affordable cost,

- the possibility to use when decorating walls, floors and roofing.

As for the cost of plates, it can fluctuate within small limits. It depends on the:

- manufacturer and its location,

- dimensions of the plate,

- raw materials used in the manufacture.

For wholesale buyers, prices for the OSB slab can be declared for a cubic meter, while for retail sale - the price of the sheet is indicated. Naturally, OSB plates for outdoor works have a higher price, corresponding to higher quality indicators. But in any case, the buyer has the opportunity to purchase a product from natural wood at a fairly low cost.

OSB board - application in various areas of economic activity

Oriented chipboard is widely used today in the construction, furniture, transport industry:

- from it they produce a continuous crate when building a sloping roof,

- it produces an outer covering of the walls of the capital structures,

- it is used as a material for creating structural elements in a single-story building,

- it is a demanded product in the repair of ceilings, walls, floors, partitions,

- from it make a reusable formwork, which can be used up to 50 times,

- it is used to construct temporary closures of construction openings,

- it is suitable for the construction of temporary housing,

- it is used to create storefronts and stands, shelves, racks, counters and countertops,

- it is floored in cargo vehicles, trailers, vans,

- produce pallets and boxes for transportation of expensive goods.

The opening of the first enterprise producing the Orient Strand Board appeared in 1982, in 20 years the OSB production volumes reached the production volumes of the traditional used material - plywood, in 2007, for example, more than 25 million cubic meters of oriented particle board were produced.

Application of OSB in construction

And now it is necessary to clarify which OSB slabs are recommended to use when performing specific construction or finishing works.

When constructing external walls and partitions, OSB3 slabs with a thickness of 12 mm can be used, the distance between the supporting bars should be 60 cm, it is also possible to use a material of a different thickness, but with an obligatory correction of the distance between the supporting structures. Internal walls or partitions can be constructed of material with a thickness of 9 to 12 mm. In order to protect the elements of the house from the influence of the damp environment, it is recommended to cover the walls of the OSB with a diffusion waterproof membrane with a high coefficient of vapor permeability in order to optimize energy efficiency and the possibility of a longer operation of the heat-saving system. This will provide more reliable protection at home and prevent the appearance of a greenhouse effect inside the structure - accumulating condensate will be discharged outside, significantly reducing the threat of mold and fungus development on the surface of walls and ceiling. For frame construction from OSB slabs, it is required to use high-quality insulation, for example, such as Izover-Classic or Izover-Extra.

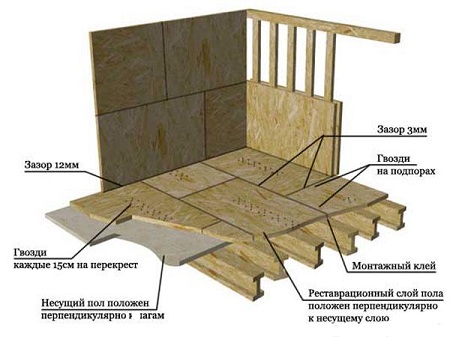

When constructing the structure, compensating clearances of at least 3 m in size at the edges of the panel are left - in case of absorption of a large amount of moisture, the plate can increase its size a little, and upon drying it may give a slight shrinkage. The presence of gaps will avoid bending or deforming the surface of the plates. The same gaps should be left in the window and doorways. To simplify the task, you can use a 3 mm thick template, which is extracted after installing the plates.

Fixing of OSB slabs can be performed with special nails, staples, screws, perforated plates. The fasteners should preferably be placed 10 mm from the edge, the distance from the corners of the panel to the location of the fastening element should be at least 25 mm. On the panels from some manufacturers already marked for mounting fasteners. Perform fastening with a step of 30 cm on the intermediate supports and 15 cm - in the places where the plates are joined. The edge of the outer walls should be fixed every 10 cm.

As the fastening elements for OSB slabs, it is not possible to use black screws recommended for working with plasterboard.

OSB can be used for interior decoration of the ceiling. The thickness of them in this case should be 9 mm. When performing indoor installation, the compensation gaps between the plates can not be left - they are transferred to the perimeter of the structure in the total size, for example - if the surface consists of five interfaced panels, then a compensation strip with a width of 5x3 mm = 15 mm should be left along the perimeter of the surface.

Laying the floor from the OSB panels is done on logs, if the material is not grooved, it is recommended that the compensation gaps are the same as for the installation of ceilings. If a floating floor is being constructed, the distance between the panels and the wall should be 1.2 cm. The material sheets are laid on the logs, perpendicular to them.

Depending on the distance between the logs, the thickness of the slabs is calculated - the closer the lags are located, the more thin the material is allowed to use. Optimal option - to give a holistic view and greater rigidity, the coating is recommended to glue the plates to the lags and glue the place of the grooved joint of all panels.

Finishing of OSB panels

After finishing the installation work, you will need to finish. The most common are putty:

- it adequately seals all the cracks in the joints of the strips of material, will give the surface a more aesthetic appearance,

- prepare it for further finishing.

Before applying putty, the surface of the board is treated with a small emery, then apply a primer (not water-based). It is desirable that the putty is transparent, the basis of it can be plaster, latex, acrylic.

As a finishing of walls from the OSB, varnishing is usually used. Apply the varnish 3-4 layers, with drying of each applied layer. Such a surface will look beautiful enough and will provide protection against the penetration of moisture inside the material. To finish the surface indoors, you can use matte compositions, the glossy surface will look more spectacular from the outside.

If desired, the plates can be covered with paint, but you can not use water-based paints. After the primer and putty the OSB slabs can be laminated or trimmed with a film.

OSB slabs for interior finishing allow to obtain an almost perfect flat surface ready for further decorative finishing. To date, OSB - is an opportunity to perform construction and installation works with the greatest economy.