Many owners of out-of-town houses face the problem of wastewater disposal. This is quite natural, because the house without running water and sanitation can hardly be considered comfortable. Everyone solves this problem in his own way: someone digs a cesspool, someone digs a drain hole, overlaying the walls with brick, stone or pouring concrete. We, within the framework of our publication, offer to consider an inexpensive and reliable option for collection and disposal of sewage - a septic tank of concrete rings, we will tell about the advantages of a septic tank, its device, and also give an exhaustive guide to the self-made septic tank from concrete rings.

Content

Septic tank of concrete rings: what are its advantages?

First, the septic tank does not require frequent visits of sewerage machines for pumping waste water. It is possible to drain the contents of a septic tank if desired every few years, for the prevention.

Secondly, concrete rings for a septic tank is a relatively inexpensive construction, and it will cost ten times cheaper than, say, a biological wastewater treatment plant. And if you have time and a great desire to save money, you can make concrete rings for a septic tank yourself, which we will discuss below.

Thirdly, all the installation and installation work is very simple, and even a person who is far from building can make a septic tank from the rings. The service life of the septic tank from concrete rings can exceed 50-60 years. And this is not the limit.

We calculate the number of rings for a septic tank

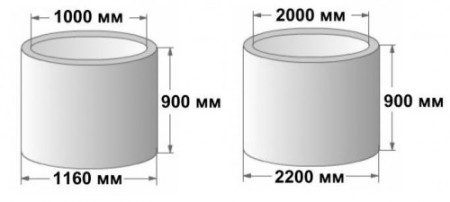

Most often for the construction of septic tanks use standard size rings with a height of 90 cm. For a normal septic tank, which does not require regular pumping, 4-5 rings will suffice. Dimensions of concrete rings for septic tanks vary from 70 cm to 2 meters.

For a country house, the best option is a concrete ring with a diameter of 1 meter. This will be more than enough for a conventional septic device. The weight of such a ring will be about 500-600 kg (depending on the thickness of the walls). Such a ring can easily be installed by 4-5 people even without the use of lifting equipment. But do not order the ring before the pit is ready - the machines that deliver the reinforced concrete products are almost always equipped with a crane, with which you can immediately drop the rings into the pit. Thus, you will save time and money.

Calculation of the volume of the future septic tank

If the water flow does not exceed one cubic meter per day, the septic tank from one well and one filtration chamber will fully cope with its task. When the water flow is from 1 to 10 cubic meters, another septic tank should be added to the septic tank. At a water discharge of 10 cubic meters, it is necessary to make an overflow septic tank made of concrete rings, consisting of 3 wells and one filtration chamber.

After the volume of the future septic tank is determined, it is necessary to choose the right place for its placement. Some important recommendations on the location of the septic tank:

- The septic tank should be located no closer than 5 meters from the basement of the house. This is necessary in order to avoid an unpleasant odor, as well as to avoid undermining the foundation in the event of an unforeseen breakthrough or leakage of sewage. From the well or the well, the septic tank should be no closer than 50 meters.

- The sewage collection device should be located on a small elevation so that the container does not fill with thawed or groundwater. The place for the septic tank must be chosen in such a way that the pipes to it are fed without unnecessary bends and angles, ideally in a straight line.

We prepare the pit for septic tank

Well, all the calculations are ready, the place for the septic tank is selected, you can proceed directly to digging the excavation. To ensure that the concrete rings do not get stuck between the walls during installation, the pit should be digged at least 30 centimeters larger than the diameter of the ring. That is, if the concrete ring has a diameter of 1 meter, then the diameter of the pit should not be less than 1.30 meters. The depth of excavation for a septic tank depends directly on the volume. Usually it is no more than 4 meters.

Often the question arises: if a pit is being prepared for an overflow septic tank - is it necessary to concrete its bottom? The answer here is unambiguous - there is no need to concretize. Sealing is only necessary if the pit is intended for a sump. For filtration chambers, this is not necessary.

Installation of a septic tank from concrete rings

When the pit is ready, you can start assembling the septic tank. As we already mentioned above, in order to drop a concrete ring weighing 500-600 kilograms into a pit, at least 4-5 physically strong people will be needed. It is possible to install a manual winch above the excavation, and if possible - to attract lifting equipment. If the rings are installed using a crane, then you need to make sure that only soft slings or a special spider for rigid lines are used, otherwise you can damage the ring.

All the rings are set one by one, strictly one above the other. Distortions and shifts are not allowed. As the connection point is set, the rings are concreted. After the concrete has dried, the seams between the rings are treated with a special mastic, to seal the structure.

After the rings are installed, they make holes for the sewer pipes. The joint of the pipe and the concrete ring must also be sealed with mastic.

On the well, a concrete or metal cover is installed from above, and the space between the walls of the excavation and the rings is covered with earth. It is good to use clay, which after drying will provide excellent additional tightness and protection in the event of an unforeseen leakage of sewage.

The scheme of overflowing septic tank from concrete rings:

Concrete rings with own hands

Very good, if there is an opportunity to buy and deliver home the concrete rings for the septic tank. But what to do when there is a need for a septic tank, but there is no money for the ring? They are, by the way, not so cheap, and you should also take into account the delivery and installation - in the end, you get a fairly round sum. In this case, you can make the rings on your own. The technology of their manufacture is simple enough, and requires only accuracy and exact following of the instruction. As a rule, everyone gets it even from the first time.

formwork for the manufacture of concrete rings

First, we determine the diameter of the future ring. As we mentioned above, the optimal diameter of the ring for a septic tank is 1 meter. The thickness of the walls should be at least 10 cm (with reinforcement) and not less than 15 cm (without reinforcement). This is a very important point.

For the manufacture of the formwork, select two metal drums according to the selected diameter. Of these, you need to make two cylinders - outer and inner. You can also use air ducts, pipes - anything that you can find. If possible, buy a plastic mold for making concrete rings. With its help, you can make rings not only for yourself, but in the future and earn some money.

If you can not find the cylinders of a suitable diameter, they can be assembled independently from several sheets of metal. A good option - cylinders of plastic barrels.

It is not difficult to make a formwork for making rings. To do this, on a large (outer) cylinder we make a marking dividing the cylinder into two equal parts.

Then a very important point: take two door or window awnings. Sheds are fixed exactly along the line of marking so that the connection is located along the marking itself.

Sheds are fixed to the cylinder with rivets or welding. The marking line is exactly transferred to the inside of the cylinder. Next, take the thinnest cutting circle, and carefully cut the cylinder in the layout, without damaging the canopies. Then cut off the bottom cap the latch on each shed, pull out the spindle and split the cylinder into two halves. The removed spindles can later be used in the manufacture of concrete rings.

Next we prepare the inner cylinder. Everything is done almost as well as with the outside, with the only difference being that the marking divides the cylinder in half. Line markings should be located one from the other not more than one third of the diameter of the cylinder. That is, as a result, one half should get wider than the other half.

In the assembled form, the inner cylinder should be above the outer one by about 10 cm. This is necessary for the convenience of pouring concrete. The outer cylinder should open easily to the outside, the inside cylinder to the inside. When the ring is ready, first release the inner form. To do this, pull the spindles out of the canopies and neatly fold the mold inside. The outer form can be removed even easier - it is simply opened outward.

technology of manufacturing of concrete rings

Work is carried out at a temperature not lower than + 8C. In extreme heat, finished products must be protected from direct sunlight. For the production of cement, we need cement, which was produced not less than a month ago (matured).

We prepare a solution of medium consistency: 2-3 parts of sand, 2 parts of gravel, 1 part of cement. We install the formwork on a flat surface. Between the inner and outer cylinder we lay the reinforcing mesh. If there is no grid, during the pouring process, a wire with a section of 2-6 millimeters can be laid in the solution in turns. Rings can be made without reinforcement, but their thickness should be at least 15 centimeters. They serve, by the way, no less than reinforced, but you need to handle them more carefully.

To ensure that the cylinders do not move when pouring, several spacer pegs must be installed in the space between them.

After that, carefully lay a layer of concrete around the circumference. The height of the layer should not exceed 20-25 cm. Now, with a wooden or metal ram (piece of fittings, a regular stick, a shovel from the shovel), gently compact the solution along the entire circumference. After the level of the mortar reaches about the middle of the formwork, remove the spacer wedges, and you can install the ears for installation. For steel production, steel wire with a cross section of at least 3 mm is used. Gradually, layer by layer, fill the entire shape, gently level the surface of the future ring, so that the joints are dense.

After 4-5 days, the formwork can be removed. The finished ring should not be touched for at least another week. During this week, constantly moisten the surface of the ring, so that the concrete is well strengthened. You can use the concrete ring after 10 days.