If the boiler house in the house is in a non-heated place, then when the coolant moves through the pipes to the heated room, about 20% of the heat is lost. To ensure that such a large volume of heat is not wasted, various heat insulators are used. Particular attention should be given to thermal insulation cast iron gate valves avk. Cast iron - a brittle material, when the liquid in the valve freezes, the body can burst. The owner of the house must take this into account and, accordingly, produce a quality heat insulation of the gate valve. The variety of heat-insulating materials allows to significantly reduce heat losses and achieve the maximum efficiency of the heating system. In the article the main types of thermal insulation for heating pipes are considered, a full review of the characteristics of each type of insulation is carried out.

Content

- 1 Heat insulation of heating pipelines. What is it for

- 2 How to properly apply heat insulation in the heating system

- 3 Materials and methods of thermal insulation of pipes. Characteristics and methods of application

- 4 Detailed analysis of heaters for pipes in the heating system

- 5 Thermal insulation for pipes foil

- 6 Draw conclusions

Heat insulation of heating pipelines. What is it for

To rationally use the thermal energy of heating systems, it is necessary to heat only those rooms that need it. The heat emanating from heating pipes in non-residential, auxiliary rooms is dissipated without benefit to the consumer, while overall system performance is reduced and energy consumption costs are increased. One of the reasons for the insulation of pipes is the probability of freezing of the coolant with a sharp drop in temperature in the street. The freezing of the entire system is unlikely, but the formation of plugs is quite common. That is why thermal insulation for pipes is an important and indispensable condition when installing a heating circuit passing through a non-heated room. Thanks to such protection it is possible to completely avoid unjustified loss of heat or freezing of the system. Also, heat-insulating materials protect the components of the heating system from possible mechanical damage, condensation and possible corrosion. Thus, the insulation of the heating system ensures:

- Significant reduction in heat loss in heating systems passing through cold areas.

- Complete elimination of freezing of the coolant.

- Integrated surface protection of pipes from external influences.

How to properly apply heat insulation in the heating system

With all the variety of heaters, it is very important to choose the right material in each specific case, based on the room parameters and technical conditions of the heating system operation. The main criteria for choosing insulating materials are:

- The location of the pipes of the heating system requiring thermal insulation

- Characteristics of the pipeline supplying heat carrier

- The temperature of the heat carrier in the system and the pipeline

- Technical characteristics of heat-insulating materials

Basic operational parameters of heat-insulating materials:

- Thermal conductivity. The lower the thermal conductivity of the material, the better its thermal insulation properties.

- Moisture resistance. This property is extremely necessary for high-quality protection of metal pipes from condensation and corrosion.

- Fire resistance and heat resistance. These parameters should fully comply with fire safety standards in heated buildings.

- Resistance to decay and the influence of microorganisms.

- Technological and the price of installation.

Materials and methods of thermal insulation of pipes. Characteristics and methods of application

Choosing an effective insulation is not a difficult matter, but given the variety of assortment of heat-insulating materials, you will have to think carefully about which one to choose to get the most effect. The material used for thermal insulation of pipes can be:

- Soft roll

- Solid piece (cylinders and half-cylinders)

- Liquid, providing a monolithic coating

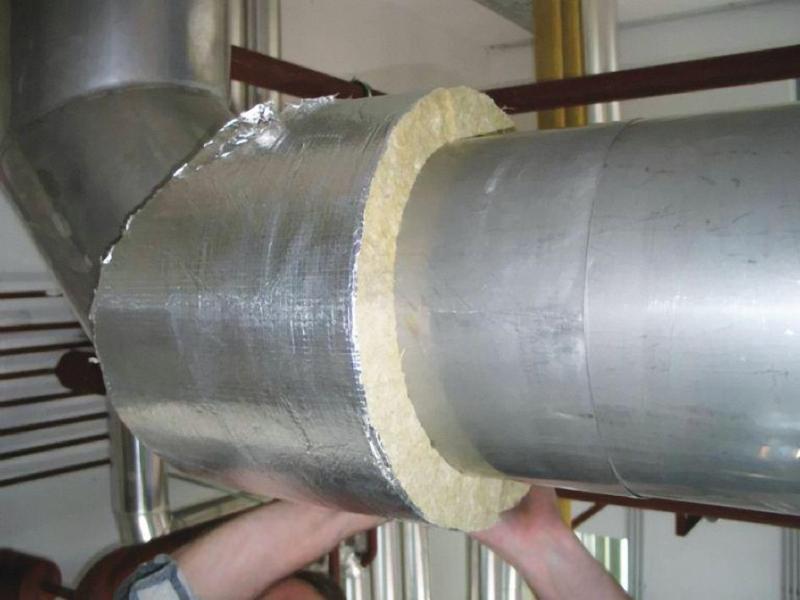

When choosing materials, it is necessary to take into account the diameter of the pipes for the correct selection of the dimensions of piece heaters. In principle, all the heaters work the same way - the thermal insulation is provided by the air contained inside the heater, but differ in the convenience of installation. Insulation of the shell for heating pipes is perhaps the easiest way of warming. Such a heater is available in the form of half-cylinders, the installation of heating pipes is made by connecting the two halves.

Due to the grooves in the half-cylinders, full quality thermal insulation is provided, the material densely covers the pipe, because of this, this method was called "shell". The most popular and practical heaters for heating system pipes:

- Styrofoam

- Mineral and fiberglass wool

- Polyurethane foam

- Foamed polyethylene

- Penoizol

- Penofol foil

Detailed analysis of heaters for pipes in the heating system

expanded polystyrene

Foam polystyrene is an inexpensive and easy-to-use reusable insulant. Sometimes this material is taken for a foam, but compared to it, it is more dense and qualitative. Thermal insulators made of expanded polystyrene are used in heating systems with a coolant temperature of not more than + 85 ° С. These heaters are available in the form of half-cylinders. The foam polystyrene shell is put on the pipe and fixed with adhesive tape or clamps.

mineral and fiberglass wool

This is a classic insulant-insulator, produced in rolls. Installation is made by wrapping pipes, fixed insulation with stainless wire, or casing. Pros - low thermal conductivity and high fire resistance. The disadvantage of such a heater is the need for waterproofing from the effects of the external environment (if necessary), since the mineral wool and glass wool easily absorb moisture, while losing their heat-insulating properties. It should be noted that ordinary glass wool is a material that is unhealthy and irritates the skin and lungs. New technologies allow the production of glass wool from non-breaking fibers, which maximizes the safety of the material. However, when installing this insulation, do not neglect the protective measures.

polyurethane foam (PPU)

Such insulation can be of two types: rigid and sprayed (mounting foam). Mounting foam, in case of emergency, can be used to insulate small sections of pipes. For the high-quality insulation of individual heating circuits, the hard form of such a heater is used. PPU is a light and strong material with a low thermal conductivity. The advantage of polyurethane foam is its high water repellent properties. The material is considered non-toxic, chemically stable, durable and environmentally safe. The installation of this heat-insulating material around the pipe is done by the "shell" method, it is crimped and fixed with the usual knitting wire, clamps, ties or staples. Withstands temperatures up to + 150 ° C.

expanded polyethylene

Such material is most often used for warming water pipes, but it can be successfully used for heat insulation of heating pipes. The material is used for insulation of steel, copper and plastic pipes of heating systems, withstands temperatures up to +70 ° С. Heat insulation material made of foamed polyethylene is a flexible insulating material in the form of a pipe with a fine porous structure. Due to the technical longitudinal cut it is easy to put on any parts of the heating system and with the help of special glue it is tightly fixed on the pipes. Due to the soft structure of such insulation is not recommended to fix on the pipes with wire, staples or tape.

penoizol

Penoizol - a liquid polymer insulation, which is applied to the pipes by spraying, in its composition is similar to polystyrene foam. Sometimes it is called liquid foam. This composite material, after hardening, forms a porous monolithic shell, which delays the heat from the heating pipes. Such a heater is universal, it is absolutely non-flammable thermal insulation for heating pipes, it withstands the temperature of the heat carrier above 100 ° C, waterproof and chemically resistant to aggressive media. On the pipes, penoizol is applied with a special spraying unit, while working strictly follow the personal safety measures. The advantage of this thermal insulation is a seamless joint.

foam foil

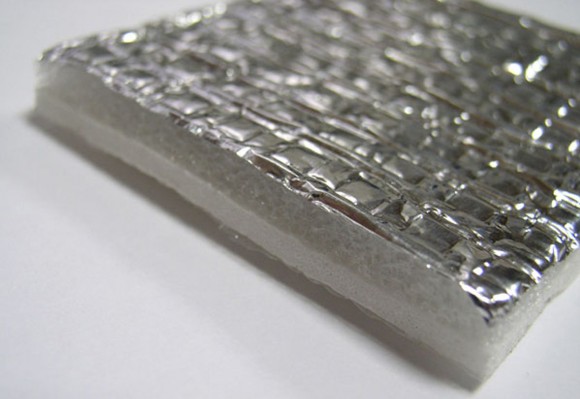

This is a relatively new material on the market, produced in rolls. This multi-layer insulation, includes a layer of foam polyethylene and aluminum foil. Penofol foil is convenient for installation, it perfectly protects the pipes from freezing, condensation and corrosion.

Thermal insulation for pipes foil

Particular attention should be paid to thermal insulation materials with the use of aluminum foil. It should be noted that the effectiveness of thermal insulation is not only in the preservation of heat, but also in its reflection. Polished foil has high reflective properties, therefore foil-insulated thermal insulation is a universal effective method of keeping coolant temperature and keeping the efficiency of the heating system to the maximum. In the production of foil insulation, a layer of base material is applied to the foil layer.

It can be: mineral wool, polystyrene foam or expanded polyethylene. The main layer, having a low thermal conductivity, provides the necessary thermal insulation. The auxiliary layer is a protective coating of aluminum foil, which has maximum reflective properties, as well as the properties of vapor and waterproofing. The principle of the reflective action of the foil is simple - the flow of heat emanating from the heating pipes is reflected back. This is why foiled insulation for pipes is called reflective insulation. Such insulation can be made in the form of rolls, plates, mats, linen, cylinders (shell).

Draw conclusions

All insulated heaters have their own distinctive qualities, they are quite simple in installation, the heat insulation of pipes with their own hands in an individual heating system is not very difficult. Each of the species is applied in accordance with the needs and the necessary operating conditions.