The plinth is a part of the wall directly above the ground. It is almost always in a hostile environment: during rainfall it receives drops reflected from the earth, in winter, in the immediate vicinity of it, snow drifts accumulate, which throughout the winter undergo numerous rapid processes of freezing and thawing, which have a uniquely negative influence on the surface of the socle. He is under the influence of a constant physical load from the walls, roofs, partitions located on top of him, forces acting on him are caused by the punching of the frozen ground. These factors, of course, have a very negative effect on the condition of the socle.

Content

- 1 Two types of house socle design

- 2 Why you need a plinth trim

- 3 Facing the socle with brick

- 4 How to choose the right brick for the lining of the base and foundation

- 5 Calculation of the brick on the plinth

- 6 The order of performance of facing works

- 7 Variants of the lining of the plinth

- 8 Advantages of the brick plinth trim

Two types of house socle design

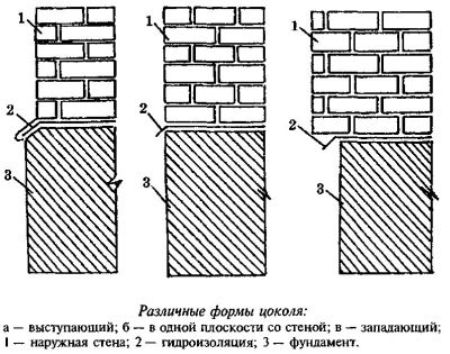

The basement, located on a level with the wall. He is an integral part of it and slightly stands for its level. The protruding base must necessarily be equipped with an additional layer of thermal insulation. With the projecting plinth, one must take into account the fact that it is practically not protected against deformation when applying mechanical damages. At the arisen desire or need, the top part of a socle of such kind can be leveled by means of plaster.

The basement is sinking behind the wall level. This type of socle has maximum protection against the harmful effects of natural phenomena. Such a base is mainly trimmed with clinker tiles. To a greater extent, finer types of tiles are suitable for this kind of finishing. This option of finishing assumes an insignificant load on the foundation.

Why you need a plinth trim

Experts advise owners who are engaged in independent construction, without fail, to protect the socle from penetration and exposure to moisture, and to choose the most reliable building material for its construction.

When it comes to finishing the socle part, the question arises involuntarily: what kind of material to trim the socle. To date, there are many options for finishing the socle part. Nevertheless, in each specific case it is necessary to choose the optimal one. under certain conditions, not every one of them can be used, firstly, it concerns the qualitative characteristics of the materials themselves, as well as their appearance, which may not quite be successfully combined with the material used for finishing the front wall.

It should be noted that the finish of the socle usually starts with preparatory work, which consists in leveling the base of the socle.

Facing the socle with brick

One of the most common options is the finish of the socle with a brick. The brickwork on the basement gives the whole building a special solidity and fits well with the other finishes of the house. One of the main advantages of brick facing is the possibility of creating a ventilated gap between the lining and the plinth. If desired, the gap can be filled with a special material for insulation. In addition, the brick is such a material, which in itself is thermally insulating, mostly hollowed.

Planning the construction work should take into account the fact that the brick lining of the socle is used only for the strip foundation. In this case, different bricks for the plinth can be used. The most suitable is a well-pressed red brick. It is endowed with a high degree of strength and practically does not absorb water. Issue its different firms, respectively, there is a difference in both cost and size.

The most cost-effective lining can be made of sand-lime bricks. But experienced builders do not recommend using this kind of building material for basement cladding.

How to choose the right brick for the lining of the base and foundation

In those cases where the foundation is designed to build heavy structures on it - you can use the usual red brick for the socle. In order for the lining to properly perform all the functions assigned to it, the material for finishing should:

- have a low moisture absorption coefficient;

- be as resistant to low temperatures as possible;

- have a high coefficient of strength.

When choosing a brick for finishing, you need to consider the following points:

- the design looks more perfect if the color of the main part and the socle are contrasting;

- the outer part of the cladding should match the style of the whole building.

Work on the facing involves several stages, the implementation of which creates a high-quality protection against the harmful effects of the environment and gives the building a presentable, finished look.

Calculation of the brick on the plinth

To calculate the brick on the plinth (for facing), it is necessary to determine the area of one unit of the facing material, it will be approximately 0.016 sq.m. for the facing of each square will require about 62 bricks or tiles of a similar size. Then, by multiplying the height of the cap on its perimeter, it is required to determine the area to be lined. Multiplying the area by 62 we get the amount of material necessary for the cladding.

Really, the material consumption can be somewhat lower - in fact, the calculation did not take into account inter-brick seams, each of which has a width of about 10 mm. But experts recommend taking the material with a margin - in the process of work, a fight may arise, the purchase of a finishing material from another batch can cause problems, such as discrepancy of a shade.

The order of performance of facing works

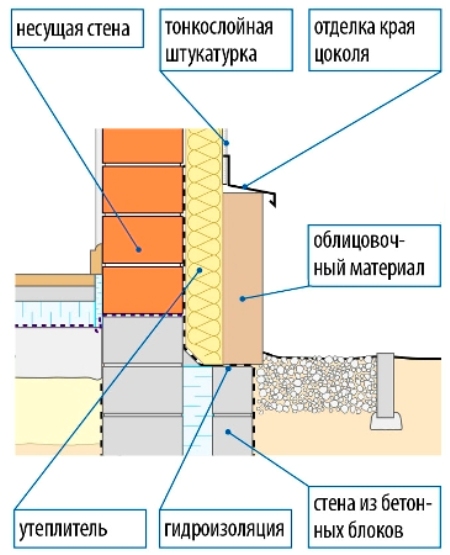

To perform the facing, proceed after the erection of the walls and arrangement of the thermal insulation system. To control the vertical and horizontal surfaces use ordinary plumbs and building levels.

To obtain a sufficient level of ventilation, the installation of the decorative part of the socle is carried out at a distance of two to three cm from the layer of the external insulation: this will help to avoid the accumulation of moisture between the wall and the layer of the lining material. When laying the first row, leave a few stitches without mortar. They will provide additional ventilation.

There are several ways to connect the facing to the supporting wall:

- Use of galvanized steel anchors. One edge is placed on the supporting wall, and the other is between the masonry of the finishing material.

- The second method involves the use of dowels. Attach it to the supporting wall, then wind it with a wire, the edges of which are fixed between rows of masonry. The fixing of the wire must not be viewed from the outside of the lining.

Each square meter of the cladding should be fixed with a minimum of five bundles to the main wall. In the horizontal direction, the ligaments should be placed at a distance of 50 to 70 cm, and in the vertical direction - every 3 to 4 rows. In places where window or doorways are provided, the ligaments should be slightly denser.

Preparation of the mixture for fixing the liner is prepared in two ways:

- 1 part of cement grade 500, clean river sand 7 - 8 parts, 2 parts lime;

- 1 part of cement grade 500, clean river sand 4 parts.

To understand that the consistency of the solution was as it should be: take a small part of the solution and roll a ball out of it, if the mixture does not stick to your hands - the solution is ready.

The grasping of the solution occurs quickly enough, so it should be prepared in small portions.

The most important requirements for facing facing:

- correctness and thoroughness of the laying of the facing material;

- accuracy and neatness of forming and jointing.

Variants of the lining of the plinth

Option 1. Chain ligation of masonry. The inner wall is formed habitually - two rows of bricks, the height is equal to the scraps of decorative bricks (they are fastened over the rows to the wall). Bundles decorate every three rows of masonry. It is more effective to use a multi-row bundle system. When the facing of the brick basement is planned with decorative material, the masonry begins with a facing verst. The first row is poked, the next two - a spoon.

Option 2. First put a series of outer lining. The next one is carried out with an ordinary brick, at the same time an inner verst is made from it. A bunch in this design is made by stamping. In this version, the chain link, firmly connect the outer and inner walls.

Advantages of the brick plinth trim

The use of the basement brick for the foundation finish allows the surface to be obtained:

more durable, resistant to moisture and temperature changes,

not requiring special care and capable of serving for many decades,

environmentally friendly and harmless to humans and the environment.

Such a finish can be repaired, if necessary. it is quite feasible to replace defective fragments with new ones. It is quite possible to install the brickwork by hand.

In the assortment of finishing materials for the socle, brick for today is advantageously distinguished by its affordable cost, and rather high quality characteristics.