The history of the bath begins in ancient times. It is well known that in Russia baths were used by the population already in the V-VI centuries AD. e. In the Russian villages, every self-respecting owner on his site invariably built a bathhouse. Quite often the bath was built not even on the site itself, but nearby, for example, near a pond or a river, so that immediately after the steam room you could dip into the iced water. Today, the Russian bath not only has not lost its popularity - on the contrary, almost every city dweller who buys a country house is wondering if there is a bath at the site. Thus, to date, a sauna on its own country or country site - the main of the construction sites. Of course, it's easiest to entrust the construction of a bath to professional builders, but this is not always possible for various reasons. And quite often the newly-made owner of his own house has to master the basics of construction, after which he is proud to answer the question of his neighbors "what kind of building are you building there?" - "I build a bathhouse". But since the bath is an object specific, first of all you need to know, not how to build it, but from what. And how to use these or other construction and finishing materials.

Content

Bathhouse. From what it is better to build

Building your own, even a small bath is quite a difficult task, requiring at least a serious theoretical preparation, since the requirements for putting a bath are often even harder than for a dwelling.

This mainly applies to fire safety and ventilation of the room, but also concerns the choice of building materials.

The question is "how to build a bathhouse?" Is not as simple as it seems at first glance, and it concerns not only the walls and the roof, but also all the elements of the structure:

- Materials for the construction of walls.

- Insulation materials.

- Steam insulation.

- Non-combustible materials.

- Materials for finishing the ceiling.

- Materials for interior decoration.

And this is not all. But within the framework of the article, we will focus on these basic issues.

Materials for walls

The material from which the walls of the baths are built, largely determines the service life of the building, as well as the comfort inside the premises.

Materials most commonly used in modern construction for bath walls:

It should be noted that brick as a material for building bath walls is not the most suitable option. The brick wall gives off too much heat, so it requires additional thermal insulation.

Brick masonry is a laborious process that requires serious construction skills.

In addition, a sauna made of bricks requires a strong foundation, and this is extra time and significant expenses.

Foam concrete in this regard is much preferable to brick, as in itself is a good thermal insulation material.

The walls of the foam block are light, and do not require a strong foundation.

The dimensions of the standard foam block for walls are 200x300x600 mm.

Thus, one foam block can have approximately 13 bricks.

The walls of this material to build much easier and faster than from bricks, materials on the topic of building a bath of foam blocks with their own hands on the Internet is very much so that even an inexperienced person will be able to cope with this.

In addition, the foam block is a "breathing" material, and at the same time does not let the damp inside the room.

Arbolite is a mixture of cement and organic filler, most often - crushed wood.

By its technical characteristics, the arbolite is in many respects similar to foam concrete.

Sold in blocks.

At the same time, the technology of production of arbolite is much simpler and cheaper than foam concrete, and you can make this building material even with your own hands directly on the construction site.

A significant drawback of arbolite - poor resistance to moisture.

Thus, the walls of the arbite should be well protected against weathering outside and from the steam inside the bath room.

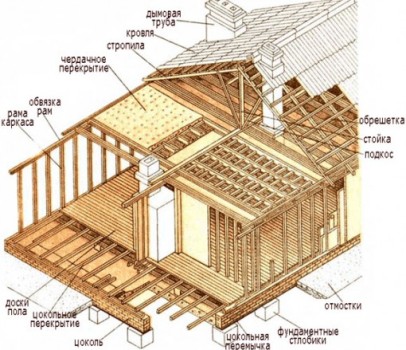

If we talk about the construction of baths of wood, we can not fail to mention the wireframe technology of construction, so popular in recent times.

This construction technology is the construction of walls from a bar of different sections in the form of a lattice construction.

Empty cells inside the structure are filled with any suitable thermal insulation material, after which the insulated frame is lined internally and externally with plate or sheet material, most often OSB slabs.

Wireframe technology is perfectly suited for building baths, including with their own hands, and allows you to save significant time and money.

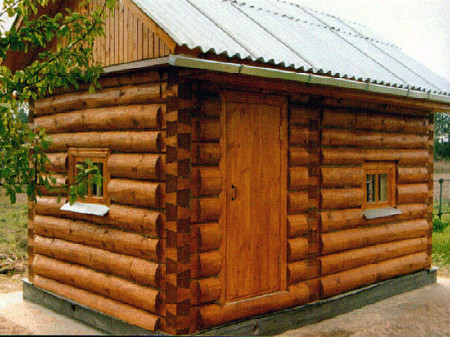

Wood is a classic and traditional material for building bathhouses on the territory of Russia.

The most suitable species of wood are pine, larch, cedar.

The Russian bath was originally built from logs, modern technologies allow to process logs in the form of round logs, glued beams. Moreover, the construction of a bath of glued beams occurs at an accelerated pace, since the bar is already soaked and dried under certain conditions at the preparation stage. Construction companies produce glulam beams in the form of environmentally friendly material, as the production uses high-quality raw materials and a safe glue type. Modern companies work in the construction market of Russia www.artholz-dom.ru, which not only produce high-quality material, but also design and build themselves.

The following types of sawn timber are used for the construction of a wooden bath:

- One piece log.

- Round logs.

- Rectangular sawn timber.

- Profiled bar.

- Glued profiled bar.

The material used can be dried or have a natural percentage of moisture.

Quite often, for log cabins, material that has a natural moisture content is used.

The more moisture in the material, the greater the shrinkage of the finished building.

For complete shrinkage of the frame it is necessary, depending on the environmental conditions, from six months to two years. The greatest shrinkage in buildings built from logs.

If you decide for yourself - we build a sauna from a bar, it is better to choose a glued beam, constructions from which shrinkage practically do not give.

Today you can buy not just sawn timber for the bath, but the ready log house of the bath in disassembled form - the "designer", in which each log is processed accordingly and is numbered, which makes it possible to erect the walls as soon as possible.

For frame construction, the sawn timber and board are most often used.

For the facing of the finished frame, traditional materials are excellent: siding, lining, bricks, etc. The building, built using wireframe technology, does not shrink.

As we already mentioned above - wireframe technology is most preferable if the construction work is carried out on its own.

Of all the above materials, wood is certainly the most preferable for the construction of baths, at least for the erection of walls.

Materials for insulation and vapor barrier of the bath

Insulation and vapor barrier are inextricably linked, especially when it comes to building an object such as a bath.

The task of heat-insulating materials is to ensure the prevention of heat leakage from the bathhouse.

All heat-insulating materials can be conditionally divided into hard, soft and semi-soft.

Best for thermal insulation of the baths are basalt heaters.

It is a fire-resistant ecological material with extremely low thermal conductivity.

Glass wool and mineral wool soft thermal insulation materials are also very popular.

As for solid heat insulators, the most commonly used are: foam plastic, expanded polystyrene foam, foam isole, foam polyurethane.

Working with solid insulation materials is more convenient and easier.

The maximum effect can be obtained by combining hard and soft heaters.

From innovations in the field of heat-insulating materials it is possible to note ecowool - one of the new, effective and environmentally friendly materials.

To prevent the impact of steam from the bath room on the insulation used vapor barrier materials.

A modern vapor barrier is a film that is pulled over the insulation.

Today the most popular vapor barrier materials on the domestic market are sold by the Isospan trademark.

If we talk specifically about the vapor barrier of the steam room, then it is best to use aluminum foil "Armofol", which has reinforcement from the glass mesh.

Material for the device of a ceiling in a bath

Under the ceiling of the bath is reached the maximum concentration of hot steam, so the ceiling in the bath needs more serious heat and vapor barrier than the walls.

In the bath, there are several options for a ceiling device:

- Panel.

- Grazing.

- Sheathed.

For the device of a false ceiling, a board is used, which is nailed from below to the bearing beams. On top of the boards stack insulation and vapor barrier.

Then the layer of waterproofing is laid and sewn up with the same board or slab material.

As you can see, the device of the false ceiling is very similar to the installation of a frame wall.

Thus, the ceiling material for the bath can be used the same as for the walls, if the bath is built using wireframe technology.

When constructing a ceiling, the boards are laid on top of the beams.

After this, the top is placed on the boards vapor barrier and insulation.

At the same time as a heater can be used loose materials - coal slag, expanded clay, and do not cover them from above.

As is clear from the foregoing, the difference between filing and laying ceilings is that in the first case, the supporting beams are hidden under the skin, and in the second - the baths are inside the room.

Sometimes as an overlap use panels from various materials - plastic, a tree, и.т.д. hence, such a ceiling is called a panel ceiling.

However, the panels work somewhat harder because of their large size.

If we take into account the fact that the interior decoration of the bath room requires some design approach, then it's better to postpone all the work on finishing the ceiling until all the inner plating in the room is ready.

And the hem of the ceiling is made with simple and cheap materials, which will subsequently be closed by decoration.

Interior decoration materials for the bath room

Finishing materials greatly influence not only the internal atmosphere of the sauna, but also the comfort and safety of people there.

The modern market offers a huge variety of interior decoration materials for baths.

But one of the best and most common is, of course, the tree. At the same time, different rooms of the bathhouse can be treated differently.

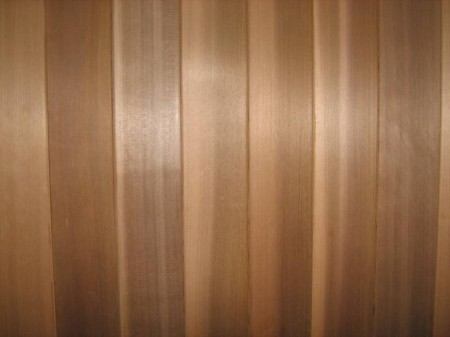

In most cases, the finishing material is a wooden board.

It is easy to guess that the most attention requires the decoration of the room of the steam room.

High temperature and humidity make their adjustments to the used finishing material, which should not only have an attractive appearance and high resistance to temperature and humidity, but also do not cause burns when it comes into contact with it.

It is highly undesirable to use coniferous rocks, since they emit quite a lot of resinous substances at high temperatures.

Finishing material should not have knots - at high temperatures they drop out.

For the decoration of the paired, it is recommended to use a lining made of such wood species: linden, aspen, alder, cedar, abasha.

Lipa and abashi, when touched by an open area of the body, take its temperature, which completely eliminates the possibility of a burn.

It is the linden that is the leader among the finishing materials for the steam room.

Aspen is cheaper material.

It is used for paired long enough in the northern regions of Russia.

Has bactericidal properties, eventually changes its color to a darker color.

Alder - a very beautiful material, well resists high temperatures and humidity.

As for cedar, it is still better to use for finishing the ceiling, as it emits a large amount of essential oils, which in a large concentration can cause unpleasant sensations.

The finishing of the washing room must be carried out with materials with high moisture resistance.

Such materials include larch lining, which is practically unaffected by rotting, and has a long service life.

To the decoration of the premises of the dressing room and locker room, there are no special requirements. They can be finished with a lining of any breed, guided by personal preferences. It is perfectly permissible to save and use cheap materials - pine, spruce, etc.

But not only wood is the basis of finishing materials for the bath.

This includes non-combustible materials to protect the walls from the heat in the area of the stove.

Natural natural minerals - talcchloride, serpentinite and jadeite are used not only as a fire-resistant material, but also as useful elements for the body.

They are able to provide a fairly effective health-improving effect due to their physico-chemical properties, in particular, to equalize blood pressure, promote immunity, and charity affect the kidneys.

But in most cases incombustible materials are necessary for facing the oven and walls near it, as well as for flooring. Jadeite is often used as a stone for an oven.

Calculation and selection of materials for the bath

The modern market of building materials has the widest choice of materials for the construction and finishing of baths.

To begin with, it is important to determine which material will be used to build the walls of the bath, and choose all other materials, starting from this.

As we have already said, one of the best materials for building a bath is a tree, which is also used for frame construction.

Bath, built on frame technology, will cost much less than a bath from a log or beam.

After you have selected the material for the construction of the walls of the room, you can select all other materials, and calculate their number.

Needless to say, that for the construction of any building requires a project indicating all the dimensions.

It is also needed to calculate the number of all building and finishing materials.

Having a ready project on hand, you can easily calculate the cost of all construction and finishing materials, as well as the approximate cost of construction work.