A chimney is an element of almost any heating system. Its purpose is to remove smoke and gases from the combustion of fuel from the room. If the house has a fireplace, a stove, a gas boiler or a solid fuel boiler, the installation of the chimney is mandatory (except - no chimneys, convectors). At the same time, all the usual traditional brick chimney is increasingly being replaced by more practical and reliable counterparts. Chimney must be properly designed and installed in every single case. The operation of the chimney must be strictly according to the rules, the violation of which is fraught with such consequences as smoke pollution of the premises, reverse thrust, carbon monoxide poisoning, fire. To prevent this, it is necessary to carefully understand the device of the chimney and the requirements for its installation and installation. And if you asked yourself the question: how to make a chimney in the house, the below information will be useful for you.

Content

Requirements for the chimney, which should be the chimney

It goes without saying that any chimney must fully comply with all fire and building codes. So, when replacing the boiler, it is often necessary to change the chimney. The chimney must be of sufficient height to effectively remove all combustion products. Its highest point should be at a safe distance from the roof. If you are not sure of your own abilities, in order to avoid trouble, the chimney device should be trusted by professionals. Velil Campaign designs, delivers, assembles chimneys. Highly qualified specialists work here, as evidenced by letters of recommendation from clients.

And if you are a "dock" of all trades, the information on chimneys provided below, we hope, will come to your aid in difficult situations.

The minimum height of the pipe above the roof is 50 centimeters. But a pipe of this height is suitable only for a flat roof, which has no protrusions. If the roof has protruding elements that are located at a distance of 1.5-3 meters from the pipe, then its heights should be the same as the protruding parts. When they are closer, the pipe should be no less than half a meter tall. If the roof covering is combustible, then the height of the chimney pipe must be at least one meter, and better - one and a half. Very important is the total length of the chimney, which must be at least 5 meters from the combustion chamber to the head.

The diameter of the chimney is calculated based on the capacity of the boiler. For example, for a boiler having a power of 3.5 kW, the diameter of the chimney must be at least 8 centimeters.

Choosing a chimney

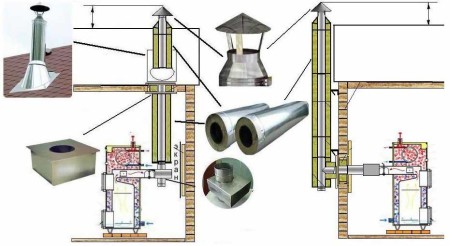

For modern heating systems, several types of chimneys are used: a coaxial chimney, a steel chimney and a sandwich chimney. Brick chimneys are practically not used today: they are not durable, quickly clogged with soot, are destroyed by condensation. A brick chimney with intensive exploitation serves no more than 5 years, after which the masonry will need to be updated. And this is an expensive and time-consuming process. Steel chimney is installed from single-layer modules.

This is the simplest and cheapest option, but at the same time, the most flammable, because the metal is very hot.

A sandwich chimney is best suited for installation in a wooden house.

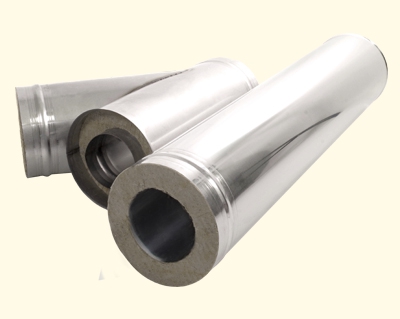

This type of chimney is a two-layer steel structure made of pipes of different diameters. The gap between the pipes is filled with heat-insulating non-combustible material. Calculating the diameter of such a chimney, orient oneself to the inner tube.

As for the coaxial chimney, it also consists of two pipes embedded in each other, between which an air layer is left to provide the insulation of the chimney. Oxygen, which enters through the air gap between the pipes, supports the combustion process in the boiler.

The inner tube is fixed inside the outer one with the help of steel bridges. An important advantage of a coaxial chimney: it can be led out to the street directly through the wall. This greatly simplifies installation and reduces the cost of construction. The coaxial chimney is installed mainly on gas boilers.

Chimney in a wooden house

Since wooden houses in our time are very popular, within the framework of this publication, we will consider the design of a chimney in this type of residential building.

To make a chimney in a house made of wood is a very serious and responsible business. Wood begins to charring already at 200 degrees Celsius, and at 300 already burns. Therefore, the chimney must be made correctly, so as not to burn the house and not be poisoned by carbon monoxide.

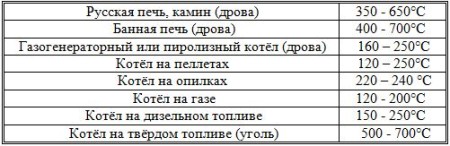

The table below shows the temperature of the exhaust gases of the various heating appliances and the fuel burnt.

For millennia, mankind lives in wooden buildings and heats them with the help of ovens, fireplaces, fires, etc. Naturally, for so long time a lot of useful experience has been accumulated, which is reflected in modern regulations on fire safety, construction and installation of heating systems. Installation and installation of a chimney in wooden houses are also regulated in documents approved by state authorities.

For example, there is such a document as SniP 41-01-2003 - "Heating, ventilation and air conditioning". It is this document that refers to the relevant authorities. According to SniP, the location of flammable objects closer than 130 mm from a concrete, brick or ceramic pipe in isolation is strictly prohibited. For pipes made of ceramics that do not have thermal insulation, this distance is 250 mm. The tree burns very well, most types of insulation, too, as far as polymer vapor barrier and waterproofing films and say nothing. Therefore, it will be unnecessary to remind you that in no case should these materials come in contact with the chimney.

abutment of a chimney to a wooden wall

Wooden wall must be isolated as much as possible from the chimney. The distance should be at least 25 centimeters. If no asbestos insulation is installed, then the chimney should be from the wall at a distance of 38 centimeters.

The resulting free space can be walled into a quarter of the brick on both sides. In the newly built log buildings, a sliding board is installed from the boards to take into account the inevitable shrinkage of the building. An adjacent side wall is attached to the shield, in which openings for air circulation are arranged.

The wooden floor in the rebuff must be covered with brick, ceramic tile or any other non-combustible material.

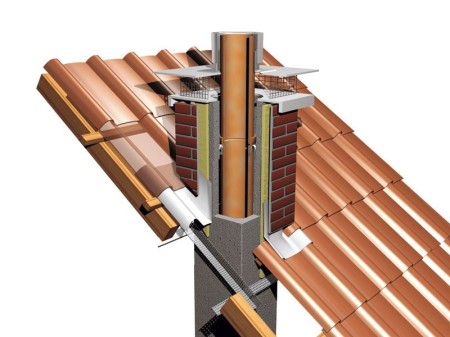

rules for laying a chimney through the roof

The distance between the chimney wall and the rafters should be at least 13 centimeters. This space is filled with rock wool. Wadding should not contain organic binding elements. If a flammable material was used in the construction of the roof, for example, roofing material, then the distance should be doubled. In places where the chimney passes, the roof is installed with non-combustible materials at a distance of at least half a meter from the pipe - slate, roofing steel, etc.

The chimney is raised above the roof level by at least half a meter if it is located not far from the pit of the pitched roof, not lower than the roof ridge at the exit of the chimney axis from one and a half to three meters from the ridge, and not below the conventional line drawn from the ridge at an angle of 10 degrees down to the horizon if the axis of the chimney comes out more than three meters from the ridge.

chimney laying through the inter-floor covering in a wooden house

The undoubted advantage is the availability of all necessary parts for the installation of modern chimneys. In the case of a floor-to-ceiling overlap, it is necessary to purchase a ready-made factory cut for the flue. It is called attic or interstorey. The internal diameter of the cutting should correspond to the outer diameter of the chimney. Next, between the beams, cut a square hole in the size of the square parts of the interstorey cutting. The hole is made with a small margin, so that it is possible to wrap the pipe with non-combustible material in several layers. Further through the hole is a chimney, the free space is filled with rock wool.

Important point: all joints of the chimney must be located outside, they can not be launched into the ceiling.

chimney flue gasket

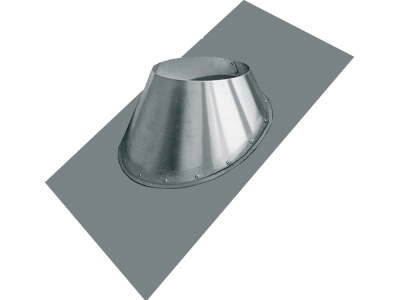

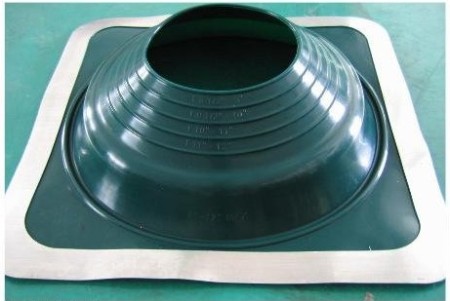

The issue of laying the chimney through the roof is solved approximately the same way as in the case of interfloor overlap. Buy ready-made cutting, in this case roof (sometimes called roofing).

Cuttings come in different sizes, and are made with different angles of gradient. It should be noted that the roof passage is a bit more complicated than the chimney laying in the interfloor. From the pipe to the wooden elements of the roof should be observed a distance of 25 centimeters from all sides. The chimney and aperture are closed by a special element called a "rat".

The top of the roof is planted under the roofing material. On top of the chimney, a stoker is put on the chimney and clamped securely with a clamp, thus providing protection against atmospheric precipitation. As in the case of interfloor overlap, all joints of the chimney must necessarily remain outside

chimney flue gasket

Very often, the chimneys are led outwardly through the wall. In this method there are many positive moments: you do not need to waste time and effort on the passage through the floors and the roof, the probability of a fire is significantly reduced. In this case, you need to add a horizontal passage through the vertical surface. If we talk about thermal insulation, then this node is no different from the passage through the inter-floor overlap. The difficulty is that the new log cabin inevitably shrinks, so it is necessary to install a sliding strip for the cutting.

Important point: if the house will be heated with a stove, a solid fuel boiler or a fireplace, spark chutes must be installed on top of the chimney.

brick chimney in a wooden house

Although the modern market offers a lot of materials for chimneys, brick is still quite a popular building material for chimneys.

Laying of the chimney must necessarily be done with a dressing. Inside the house, the brick is put on the lime mortar, and on top of the roof - on the cement mortar. It is inadmissible to use hollow bricks for building a chimney. The seam between the bricks should be no more than 1 centimeter. Plastering chimney inside is prohibited. Since a brick chimney weighs pretty well, an independent foundation is needed.

Over time, brickwork inevitably begins to break down under the influence of acid condensate, the debris falls down and gradually narrows the chimney. The internal surface of the chimney is uneven and rough, which causes the soot to accumulate inside. To reduce all these shortcomings to a minimum, a pipe from the asbestos cement is put into the smoke channel. The space between the pipe and the walls of the chimney is poured with concrete or cement mortar. This method is called "sleeve".

ceramic chimney

Recently, chimneys made of ceramics are often installed in wooden houses. Ceramic chimney is a modular, modular structure. The inner tube of the chimney is made of a durable ceramic resistant to high temperatures and acids. The internal surface of the chimney is smooth, the soot on it practically does not settle. Due to the large weight for the ceramic chimney, it is necessary to make a foundation.

chimney of sandwich tubes

This type of chimney is very well deserved popularity. It is simple and convenient to install. The construction weighs a little, it does not need a foundation. Smooth internal walls do not accumulate soot and do not interfere with the flow of draft. The inner tube is made of acid-resistant stainless steel.

Choosing a chimney for a particular heating system, it is necessary to remember the temperature of the flue gas (see the table above). Thus, the thickness of the walls of the inner steel pipe should not be less than 0.5 mm for gas boilers, as well as boilers for diesel fuel and pellet boilers. For furnaces, fireplaces and boilers on coal - 0.8-1 mm. The layer of thermal insulation should be 10 centimeters for furnaces, boilers on coal and fireplaces, for automated boilers - 5 centimeters.

https://www.youtube.com/watch?v=7jiCq3rE_98