Long since bathhouse in Russia has been universal. It not only performed its basic function of keeping the human body clean, but was also widely used for the prevention and treatment of various diseases, and in the villages - even for delivery. Now the bath is practically ousted from our life, but there are still a lot of true connoisseurs, for whom a visit to a bath is not just a hygienic procedure, but an opportunity to relax and unwind after a week of work, to meet friends in a quiet home environment.

Content

- 1 We choose the project of a bath

- 2 Bar for a bath, how to choose the right one

- 3 Optimal dimensions of the bath

- 4 The order of construction of a bath

- 5 Foundation construction

- 6 Walling

- 7 Roof erection

- 8 Carrying out of communications

- 9 equipment and finishing of premises

- 10 Choosing a stove for a bath

- 11 Helpful Tips

We choose the project of a bath

Currently, owners of private houses and cottages can easily put a bath on their land. With the appropriate financial capabilities, the availability of a place to build a bath and the reality of the project, everything will depend only on the owner's imagination. To ensure that the bath does not cause trouble to its owner, in designing and building it is worthwhile to worry about water resistance, fire and electrical safety, environmental friendliness and a number of other issues.

Small baths were always built from wood primarily because of its availability. Now also the cheapest, simple and fast solution, including for self-construction, will be a wooden sauna with the minimum necessary number of rooms.

The choice of the bath project depends on many factors: financial capacity, climate, soil, size, shape and profile of the land plot, availability of communications. There are a huge number of technical projects, but there is no one universal that would satisfy everyone. The minimal set of rooms of a traditional bathhouse includes only a dressing room and a steam room, while modern projects of luxury baths can additionally contain a swimming pool, a bathroom, a hall, a living room, a rest room, guest rooms, a kitchen, heating, technical and other premises. A good material for the construction of such a bath is a beam of 100 × 100 mm, 100 × 150 mm or 150 × 150 mm. The use of a thicker bar is preferable, since it will allow better storage of heat in the premises. The main advantages of a wooden bath - low cost in comparison with brick construction, speed of erection, b aboutgreater environmental friendliness and heat resistance.

Bar for a bath, how to choose the right one

Wood as a building material is known from antiquity and nowadays it still enjoys well-deserved attention. It is necessary to note such positive qualities of wood as ecological compatibility, low weight, high heat resistance, simplicity in processing, low cost in comparison with other materials. But on the other hand, wood has a low resistance to moisture and high fire hazard. There are such modern ways of processing sawn timber, as impregnation with antiseptic means and fire retardants, which allow to get rid of these drawbacks.

As a result of processing softwood and hardwood, various types of timber are produced: timber, board, veneer, sleepers and others. Raw materials are pine, spruce, linden, maple, oak, poplar, birch, but most often pine sawn timber is used. This is explained by the fact that the pine has a large distribution area, there is a sufficient amount of resin in its wood to prevent decay, and in terms of price / quality ratio, sawn pine is better than other building materials.

The beam is treated with lumber with a thickness of at least 10 cm. The starting material for the production of logs is logs. Depending on the number of processed longitudinal sides, the beam can be two-cant, three-cant and four-cant.

The bars, which as a result of processing acquire a circular section, are called rounded. To ensure that they fit snugly against each other, a special rounded groove is made on the bar. The buildings made of rounded timber look like logs in appearance, which gives them special beauty.

If the beams are made by gluing and pressing individual boards, they will be called glued. During the pressing, the structure of the wood is broken and, due to this, shrinkage of the building is reduced.

During the construction of wooden structures, a profiled beam was widely used - an additional processed beam, on the opposite sides of which grooves and studs were made. Due to the given profile and the same size and shape along the entire length, the beams are laid almost without a gap, so it is easier to assemble the structure, improve the insulation and appearance. In addition, the building of the beam almost does not shrink.

When buying lumber, it is advisable to have a roulette with you to make sure they match the declared sizes. It is not uncommon for unscrupulous sellers to try to sell a product that has smaller dimensions. In addition, if the sizes of individual specimens differ significantly from each other, then during construction, they will need to be adjusted, which will require considerable time and effort. The beams and boards can be independently checked for bends and deformations by pulling on them a thin strong cord. It is also worth paying attention to the smell of wood - it should have a pronounced flavor. The smell of rot will speak about the damage to the material by the fungus.

When choosing sawn timber, it is necessary to carefully examine the structure of the wood. Due to growth or distortion of the tree trunk, the quality of the product is reduced, as indicated by the large differences in the texture of the wood. A significant number of knots and cracks indicates a reduced strength of sawn timber, and wormholes also spoil the appearance.

Defects in the form of cracks, falling out or darkening knots, changing the color of wood from fungus damage, may be the result of a violation of the drying process or storage conditions. Rotting changes the color of the tree and sharply reduces the strength, so the purchase of such lumber should be immediately discarded.

The moisture content of wood is a very important parameter, which significantly affects the longevity of sawn timber, dry wood is much longer. Unfortunately, it is impossible to check this important parameter without a specialized device, so you have to believe the seller for a word. If there is an opportunity to compare the weight of the product with the natural moisture, and the past drying procedure, the first will be somewhat heavier.

In order to sell low-quality goods, the seller can wood damaged by a fungus, treat with a bleaching agent and sell as a quality material. It is almost impossible to determine such a forgery by sight.

More stringent requirements are imposed when selecting materials that refer to visible surfaces or are used for finishing, since they have a decorative purpose. When buying lumber, you should pay attention to the fact that they must be treated and have protection from fire, moisture and fungus.

If you find the listed wood defects and high humidity, you should cancel the purchase and try to find another seller.

Optimal dimensions of the bath

The bath can have a variety of shapes and sizes. The bath can be single-storey, multi-storey, it can be joined by terraces, verandas, attics, bay windows, on which the size of the bath depends. Large baths with all kinds of outbuildings are more convenient and comfortable, but their cost is very significant.

For a small and inexpensive sauna from a wooden beam, the following rooms will be optimal: a steam room, a shower room and a rest room, which also functions as a dressing room and a dressing room. The number of rooms of such a bath is minimal, but quite sufficient for a comfortable stay in it of several people. In the construction can also be absent terrace and porch, thereby saving money and building materials.

Experience has shown that for a small bath for 4 people the size of 4 × 4 m will be optimal. It is quite compact, can fit almost anywhere and has three rooms. Of course, you can not equip a swimming pool in such a bath, but all the essentials are present. The height of the ceiling should be at least 210 cm. As the hot air rises, when the height of the room increases, the heating costs will increase.

The beam as a building material is chosen mainly to reduce the cost of construction and simplify the construction process.

The order of construction of a bath

Mounting the bath with your own hands will increase the construction time, but it will significantly save money.

Construction of the bath includes the following stages:

- project development;

- foundation construction;

- erection of walls and roof;

- communication;

- external finishing of the bath;

- interior finishing.

Foundation construction

The foundation for a log-house, depending on the size of the building and the materials used, can be of the following types:

Depending on the size and material of the building, different types of foundations can be used.

- The columnar or pile-screw foundation is a pillar that is installed in the corners of the structure and at high load points. The space between the pillars is concreted. This type of foundation can be used for light buildings, including saunas made from a bar on sandy soils.

- Tape foundation, which is a concrete strip, which is poured around the perimeter of a heavy stone structure and gives it good stability on soils with a deep groundwater level. Can also be used for baths.

- Monolithic foundation, installed under the entire construction area. Thanks to the large area, this foundation is designed for heavy buildings and can be used on complex soils, with a high level of groundwater.

- A mixed foundation, which combines the first two types and is used for water-saturated soils, but it is rarely used for bath construction.

The principle of columnar foundations is that it must pass all weak soils or soils above the depth of freezing and the support part rests on more reliable soils or grounds that are below the depth of freezing. In most cases, such foundations for light structures are rational in view of the fact that the cost of constructing such a foundation is much less than that of a monolithic or tape one, because less work is done on digging trenches, reinforcing and pouring concrete, arranging the formwork. The pillars for the foundation can be various: brick, made of ready-made concrete structures, concrete monolithic, wooden from oak, larch, cedar.

The bearing capacity of the columnar foundation is much less than the foundations of another type, since the area of the support part is much smaller. In a monolithic and band-like foundation, the loads are distributed almost identically to the whole of its surface, and the columnar foundation is not a single unit, the pressure on its individual parts is different and, therefore, uneven shrinkage can occur. For this reason, the columnar foundation has restrictions on use, but it can still be used successfully for frame and log houses. To build a bath you can use any of the abovementioned foundations. However, considering that for the device of the columnar foundation much less material and labor is required, and the bath of the bar has a small weight, then such a foundation will be the most optimal.

To install the column foundation in the previously marked places, digging pits depths exceeding the estimated 0.3 m for the arrangement of gravel-sand cushions. To reduce the forces of swelling, the foundation must be buried below the depth of freezing of the soil, which depends on the region. The pillars of the foundation are installed at a distance of no more than 2 m at the corners of the erected bath under all load-bearing walls. Cushion material is poured into the pit, shuttering and reinforcement are installed, and for the subsequent binding of the grillage to the foundation, the reinforcement must come out from the upper part no less than 15 cm. As a formwork, it is possible to use a roofing material, which is shaped into a pipe and fixed with a wire.

The filling should be carried out in stages, 20-30 cm, preferably using a vibrator for the concrete mix. The built foundation must be protected from moisture by ruberoid, waterproof mastics or other materials, after which the pits around the pillars may be covered with earth. At the top of the pillars of the foundation, a wooden or monolithic harness is arranged, which subsequently serves to construct a floor structure with the subsequent installation of a wall structure.

Increase the load-bearing capacity of the foundation and smooth the uneven shrinkage can be achieved by equipping a low grillage in the form of a shallow band. Since the grillage will be in the freezing zone, it must be insulated and equipped with a sand cushion of coarse-grained sand.

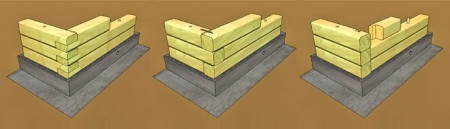

Walling

On the foundation with a bar of 150 × 150 mm the first crown (the lower strapping) is installed. The foundation and the lower piping must be treated with means to protect them from moisture. The floor beams and internal partitions are made with a 100 × 50 mm beam. For greater stability of the floor, the lags are installed on the edge, the floor is covered with a black floor with boards 25x150 mm with obligatory thermal insulation. On the finished floor, the finishing floor is covered with any convenient material.

Several methods can be used to erect cobblestone walls: "vpoldereva", "back-and-forth", on dowels, of which the simplest is "back-to-back", since it does not require additional processing of the beams. The bars are alternately stacked on top of each other, to prevent displacement, they are joined by nails, and the corners are stapled. After the construction of the frame, the walls are cut by 100-150 mm logs.

The building from the bar has a good view, so it can not be externally externally, but additional processing is desirable to protect it from insects and moisture.

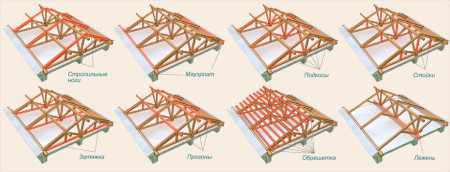

Roof erection

Baths can be covered with a saddle or gable roof. One-pitched has a very simple device, with its equipment used a minimum amount of building materials. The drawback of this design is the need for frequent cleaning of snow or fallen leaves with a small angle of the roof slope.

For a gable roof, this lack is absent, it looks more aesthetically pleasing, it is possible to equip an attic, but due to the relative complexity of the roof device, the consumption of materials increases and the process of its installation becomes more complicated. The roof must withstand the weight of snow and strong wind, but at the same time it should not be heavy, otherwise the frame of construction can not stand.

The basis of the roof is the rafter system. For a small bath it is advisable to install a suspension system of rafters, since it is simpler and cheaper. All rafters must be connected to each other and make up a single structure. On the top of the walls you need to install the tightening so that there are no lateral loads on the walls. Tightenings will simultaneously perform the functions of floor beams, so their length should be greater than the width of the building by approximately 0.4 m on each side. This stock will protect the building from water, which will flow down the roof. All connections should be reinforced with the help of metal connecting elements. When choosing the angle of the roof slope, it should be borne in mind that the higher its value, the higher the roof sail and the larger attic space, but less snow will accumulate.

On the temporary stands, a ridge run is installed, to which the rafters will subsequently be fastened. Before the manufacture and installation of rafters, you should make a template for them, by attaching the board to the ridge run and the mauerlat, mark the required lengths and lines of the cuts. According to the patterns, the necessary number of rafters is manufactured and installed, which are fastened to the Mauerlat and nailed to the ridge run. To the rafters fastenings are fastened and bolts are fastened, and then the fastening points of the crossbars are strengthened with bolts or studs.

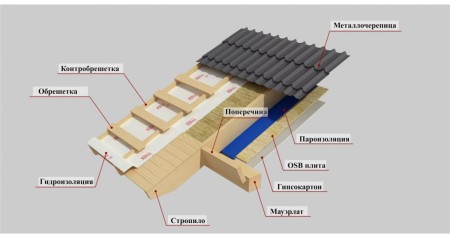

After the installation of the main part of the rafter system is completed, temporary stands are removed, which kept the ridge run, laying layers of vapor barrier, thermal insulation and waterproofing. Steam insulation material is attached to the rafters on the inside with the help of staples or galvanized nails, butt joints are sealed overlapping tape. Over the vapor barrier layer, the space between the rafters is filled with a layer of insulation, and a film of underlaying waterproofing is attached to the outer part of the rafters with nails or staples. Next, a crate is installed, evenly distributing the load to the rafters, and the roofing is laid on the crate.

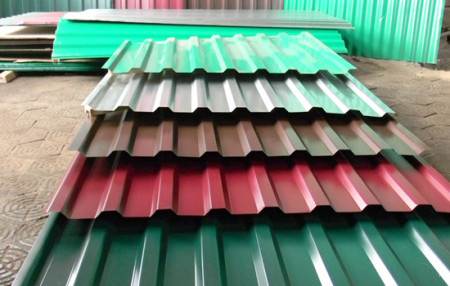

Various roof coverings can be used for roofing, ranging from straw and simple roofing material to shale and copper coatings, but for a small building it makes no sense to use expensive materials. For a bath as a coating, such inexpensive sheet materials as slate, corrugated board, Euroshafer are successfully used.

Slate - pressed wavy material from asbestos and cement, inexpensive, with a long service life, does not heat very much in the sun, however it is heavy and has a slight resistance to shocks.

Profiled sheeting - galvanized steel, which is given a certain profile by means of the press, it is lightweight, has high rigidity, tightness, easy to install, but rusts when the outer coating is damaged and has low heat and noise insulation.

The Euroshift is produced by pressing cellulose-cardboard fibers, glass fibers and polymeric materials with special impregnations, is in the price category between slate and corrugated board, is lightweight, durable, easy to install, has good noise insulation, however combustible. For a small sauna, the roof, covered with euroshire, will be the best solution for the price / quality ratio.

At a roof inclination angle of more than 15º, the distance between the beams of the crate should not be more than 60 cm, the end lap of the euro-sphere - 17 cm, and the lateral one wave. To cut the sheet, you can use a hacksaw for wood. On the canvas it is desirable to drip the oil so that it does not get stuck in the sheet. Euroshield is attached using nails.

Carrying out of communications

The places of supply of electricity, sewerage and water are determined even at the stage of laying the foundation. In order not to drill holes for pipes in the elements of the foundation, sleeves can be laid when assembling the formwork. The diameter of the sleeve should take into account the diameter of the pipe with a layer of thermal insulation. Since the pipes of the sewerage and the water pipe, passing through the foundation, turn out to be in the lower part of the building, where there will be no access after the flooring, it is necessary to worry about the communication of the bath before installing the floor in order to install them in the underground space.

sewerage

From the bath, the used water should merge somewhere. Well if there is a sewage system on the site, then it only remains to connect to the existing communications. Otherwise it is necessary to equip a drain hole. It should only be taken into account that the pit is not suitable for areas with a high level of groundwater.

One of the ways to equip the drainage pit involves the use of a metal or plastic two-barrel barrel with holes in the side wall after 15-20 cm and a nozzle embedded in the top cover. The barrel is wrapped on all sides by a web of permeable material, for example, non-woven geotextiles, which will prevent the entry of solid particles into the container.

In two or three meters from the foundation of the bath it is necessary to excavate the foundation pit, pour 20-30 cm of gravel or gravel onto the bottom and install the barrel upwards with a branch pipe. Sewage pipe, which runs under the slope from the bath and pit, is connected to the branch pipe and the space around the barrel is filled with gravel.

Another way of using instead of a barrel is to use one-on-one unnecessary car tires with the cuts made in them.

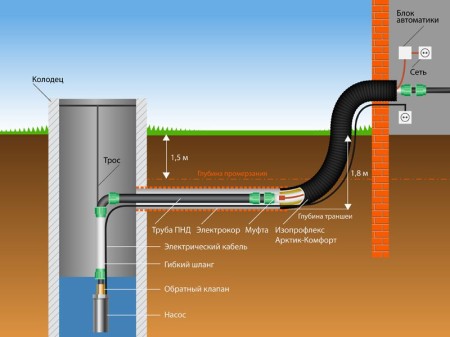

water in the bath, options for piping, installation

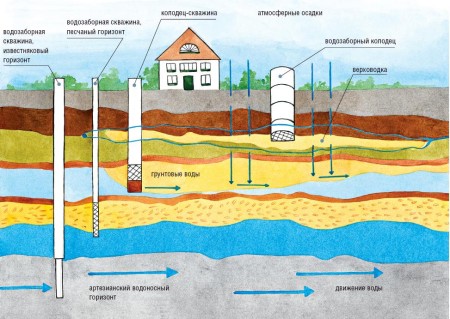

Any bath can not do without clean water and it is good if a central water supply is supplied to the site. In his absence, we will have to look for alternative sources of water. Very costly is a well for a bath, which requires a large amount of work, as drinking water that has undergone natural cleaning, as a rule, is at great depth. An autonomous source of water can also be a well for a bath, but here the type of soil, the depth of the aquifer, the distance to sources of pollution, the quality of water will be decisive. Since water in the well or borehole is below the surface of the earth, it is mandatory to use the pump to supply water to the room. In the event that the water in its composition does not meet hygiene requirements, installation of cleaning filters will be required.

If you do not plan to use the sauna in the cold season, it is worthwhile to consider draining water from pipes and sanitary products in order to avoid damaging them. If in the winter the bathhouse is operated, it is necessary to ensure constant warming up of premises to positive temperature, thermal insulation, or, better, the heating system of external pipes with a special wire.

For heating water it is recommended to use a storage electric water heater. For the bath in question, there will be enough boiler with a volume of 50 liters. If the area allows, it will be more convenient to install it in the shower room, otherwise - in the recreation room, after having decorated the boiler under the wall cabinet or in some other way. Instead of a storage water heater, a more compact flow-through can be used, but it has a aboutthe maximum power consumption, which may not be calculated electrical wiring. For the distribution of cold and hot water, it is advisable to use metal-plastic or polypropylene pipes, pipe wiring has a simple circuit and it will not be difficult to make it by oneself.

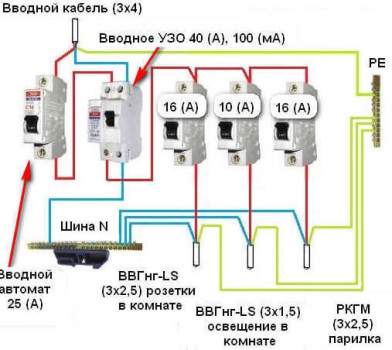

power supply of the bath

If the bath does not plan to heat water, use the TV and a music center, then you can do without electricity by installing standalone LED lights on batteries or batteries. But if you want to enjoy the benefits of civilization, then you need to connect the sauna to the power grid. It is cheaper, easier and faster to lay an air line to the bath, for which purpose a specially designed SIP wire is used.

To protect against short circuit, a 16 or 25 A circuit breaker should be installed, unless another powerful consumer of electricity is planned to use, other than a water heater. After the machine, a residual current device (RCD) must be installed for a trip current of up to 30 mA, which protects the person from electric shock. After the RCD, the sockets, light switches and lights themselves are switched on. In the steam room and shower room, no cables should pass, the lamps are installed only in a waterproof design, and the light switches are placed outside. The best solution is to use in rooms with high humidity LED light fixtures included through a low-voltage isolation transformer.

Wiring inside the bath is desirable to be done in non-flammable plastic boxes over wooden walls with copper wire cross-section 2.5 mm 2 for sockets and water heater, and 1.0 mm 2 - for fixtures. Through the wooden constructions the wire must pass in a metal pipe, the sockets and switches are installed splash-proof.

equipment and finishing of premises

The steam room should have a sufficient area for sitting and lying. Experts believe that for a comfortable stay of four people, the steam room should have dimensions of at least 2.0 × 2.5 m and include at least two, preferably three shelves. When calculating their width and height, it is necessary to take into account that the normal width of the shelf on which the person sits in the steam room should be not less than 0,4 m, and for a person with raised feet - 0,9 m. The distance between the top shelf and the ceiling is not selected less than 1 meter, so that the visitor could quietly rise. Shelves should be placed from each other in height by 0,3-0,45 m. For air circulation between the shelf boards it is desirable to set a gap of about 3 cm. The surface of the shelves must be carefully treated to avoid splinters.

It is not recommended to install in a steam window to reduce heat leakage, however, if there is still a need, it is worth equipping it as low as possible or installing a window with a double-glazed window. Also, the door should not be high and be carefully adjusted to eliminate cracks. Finishing the steam room should be especially careful, because Slits are a source of heat leakage. For the purpose of additional insulation, you need to insulate the walls inside, for which you can apply mineral wool and foil insulation.

The ceiling in the steam room is covered with a board 20-30 mm thick, the walls are lined. For flooring, you can use boards or floor tiles. Usual nails will rust with time, so when finishing the bath you need to use galvanized or coppered nails, other fasteners made of stainless steel or non-ferrous metal.

The shower room is a room in which moisture is present, therefore, the shower enclosure must exclude water from getting into places where it is possible to decompose the material and form mold. For walls and floors it is better to use wall and floor tiles with increased moisture resistance. The floor in the shower room should be without cracks and have a slope toward the drain hole, through which water is diverted into the drain pit. A good solution is to install a closing shower.

The rest room, which simultaneously serves as a dressing room - the face of the bath, so the decoration of the rest room is a very important task. Most often these rooms are finished with wood. It has a beautiful appearance and well retains heat. The floor of the tile or porcelain stoneware will be cold, so it is better to make it from wide boards. The ceiling is also made of boards, the walls are lined with lime or aspen carving.

Everyone wants his bathhouse to be beautiful and therefore has the right to choose the finishing materials at his own discretion, the main thing is to approach this choice carefully.

Choosing a stove for a bath

The oven installed in the bathhouse should not only heat the room, but also provide the necessary humidity in it, therefore, in addition to the hull and furnace, the furnace contains such an important part as a steam generator. The simplest steam generator is a hot stone, from contact with which water turns into steam. It was from here that the name of all the furnaces for the bath-heater came.

By the type of materials from which the furnaces for a bath are made, they can be divided into several categories:

- stone;

- brick;

- adobe;

- cast iron;

- steel.

The most expensive is the installation of a stone furnace. For her in a small steam room is not enough space, besides, it is necessary to provide a foundation for installation. Brick furnaces along with adobe have low cost, but they are also unsuitable for small rooms. As for the metal ovens, thanks to the affordable price, small size and ease of maintenance, they are in deserved demand.

To warm up the steam room, a stove is used, which is heated by an energy source. According to the type of fuel used, the sauna furnaces are divided into electric, gas, wood, pellet.

Electric heaters are easiest to use, they require a lot of electricity. Gas furnaces, like electric ones, are very convenient to use, but only with centralized gas supply. Pellets are a good fuel, but it is not widely distributed. That is why the main stoves for saunas are wood burning.

Currently, there is a huge selection of industrial furnaces. They can have a variety of shapes and power. Furnaces must meet the stringent requirements for heat resistance and refractoriness of the material from which they are made.

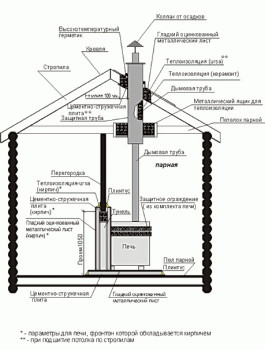

The most common and affordable stoves for baths are metal made of stainless steel and cast iron. There is a huge selection of furnaces: with a solid metal door and a door with glass, with ordinary and panoramic glass, with a conventional and remote fireplace, which allows you to draw from a rest room, with and without stones baskets, there are models with a steam generator. Iron heater for its simplicity, reliability, economy is deserved attention among lovers of steam. When installing the furnace to ensure fire safety it is necessary to carry out the protection according to the recommendations of the manufacturer.

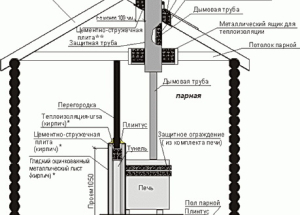

Any furnace operating on the principle of combustion of fuel has a chimney for removing combustion products. A vertical or horizontal chimney can be used for a bath. Vertical chimney provides the pipe outlet through the ceiling and roof, which greatly complicates the work on its installation. It has good traction, is less clogged, but has a large heat loss. The horizontal chimney has a pipe outlet from the room through the wall, the installation of the chimney is simpler than that of the vertical one, it has less traction, it often requires the installation of forced ventilation, horizontal sections are often clogged.

The chimney is a very responsible part of the furnace, because, incorrectly installed, it can cause people to die as a result of fire or poisoning by combustion products. In the sales network there is a large selection of sets of products, so it is safer to purchase a ready-made chimney and strictly follow the recommendations for its installation.

It should be noted that anyone who wants to build a bathhouse is free to choose the project, materials, way of building in relation to their tastes, wishes and financial possibilities, and this article will help in this choice.

Helpful Tips

- if you want to save on materials, then the purchase of sawnwood should be done in winter, since wood - the goods are more seasonal and at this time prices are much lower; various actions are offered;

- when choosing it is worth buying lumber with fewer knots;

- for the finishing of the bath can not use particleboard and fiberboard, which when the humidity is swelling, and from the heat emit harmful substances;

- to reduce the humidity after the bath, it is desirable to equip with forced ventilation;

- wood - the material is flammable, so it should be treated with flame retardant;

- when building walls from a profiled beam, the sides to be joined should be treated with an antiseptic;

- the bath from the bar less settles, which allows earlier to begin finishing work;

- the bath should be equipped with serviceable fire fighting equipment.