The dream of any host is solar collector by hand, and the dream of any electrician is the wiring without any connections. But in practice it is necessary to connect the wires: twist, clamp into terminals, weld or solder. Correctly and correctly connected wires are the guarantee of a long and trouble-free operation of electrical wiring and household equipment - that's what specialists think. It does not hurt to listen and adopt the ways of connecting copper and aluminum wires.

Content

The first acquaintance with the wires

Petrovich remembers his first acquaintance with electricity as he does now. It happened in the fifth grade, when a small, inquisitive and smart Petrovich began to connect the wires of the cord of the burned iron. As expected, in his opinion, blue with a blue wire, and red and red.

It then jerked the current, and specifically. Already now, several decades later, being the chief electrician of a small enterprise, Petrovich recalled that case with a smile. Known ways of connecting conductors always cause some misunderstanding: "So it is possible or impossible to connect aluminum and copper wire?". In order to finally dot the "I", let's look at the methods of connection most commonly used in the practice of electrical engineering.

Types of wires and cable

The most common electrical cable is an aluminum wire. Good conductive properties and relative cheapness of aluminum wire make it possible to use this variant of the conductor everywhere.

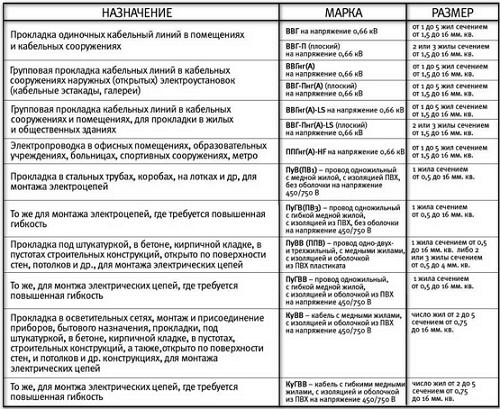

There are the following types and brands of aluminum wires:

• power cable

• control cable

• for overhead transmission lines.

However, in comparison with copper wire, aluminum has, unfortunately, little mechanical strength and reduced contact qualities.

To be definitively confident in the quality of electric lines, it is preferable to use a copper wire.

The scope of copper wires is more extensive, due to the excellent performance of the material.

But in order not to repeat the mistakes of the young Petrovich, it is not recommended to connect copper and aluminum wires directly.

The reason for this is the electrochemical incompatibility of the metals of the wires being connected. But for connecting aluminum and copper wires, there are certain ways.

Ways of connecting wires

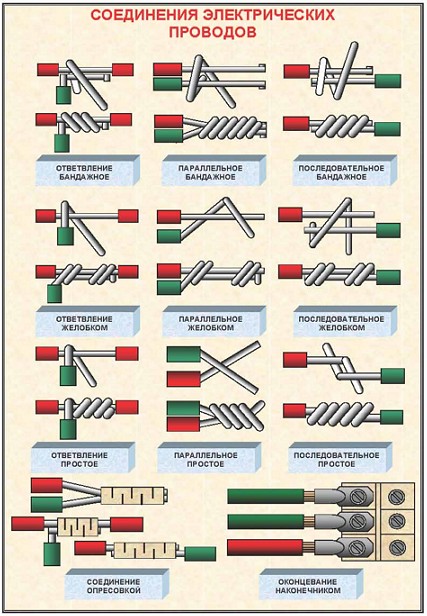

There are the following ways of connecting the wires:

• twist

• Bolted

• Welding and soldering

• Screw clamps

• WAGO terminals

The most accessible, in terms of simplicity of design, are twisting and bolt connections of wires.

twist

Type of connection twist is designed to connect single-core aluminum wires. True, aluminum wires are not used when installing internal wiring, but twists are still used. The grandfather's method of "cold" welding is to tightly twist the turns of the wire. The length of twisting reaches up to 50 mm. It does not hurt to remember that in the twisting it is forbidden to connect wires from different types of materials, namely copper and aluminum.

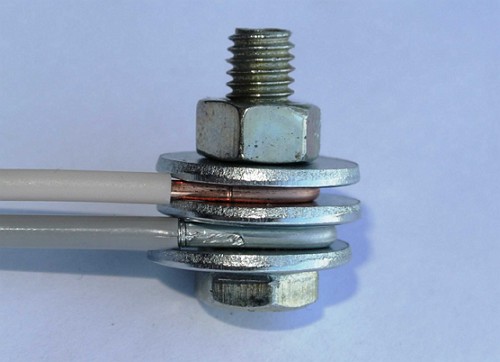

bolted connections

Connections of bolted wires are used in high-current circuits, therefore, for a wiring in an apartment or a cottage, the bolted connection is not used in view of the cumbersome structure. On a powerful bolt put on a suitable size washer, the conductors wrap around the base of the bolt. If there are two conductors, namely aluminum and copper wires, then a steel washer is laid between them. Solid design ensures a long period of wire connection.

welding and brazing

Welding and soldering wires can be safely called the most reliable ways of connecting. These types of connections are used for centuries, not paying attention to a fairly time-consuming process that requires certain skills in the work. Soldering and welding are subject to wires of any type, the main thing is to choose high-quality solder and flux, and also a powerful welding machine.

screw clamps

Modern screw clamps for conductors are successfully used for connecting wires of household lighting devices, switches and electrical outlets, switchboards. Thanks to screw clamps, accurate and quick installation will be guaranteed.

Moreover, with the help of screw clamps it is allowed to connect wires from different electrochemical metals. To connect wires made of aluminum and copper is the best option. In addition, there is free access to the connection points of the wires (clamps).

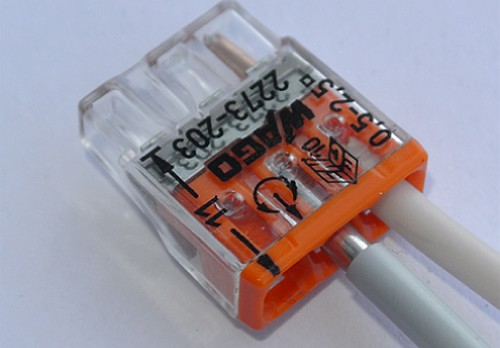

wAGO terminals

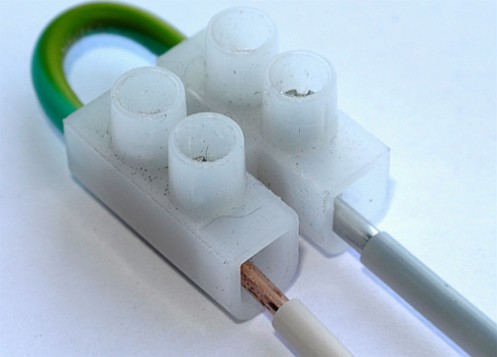

This method of connecting the wires to electricians liked the simplicity, speed and convenience of installation. No additional devices or manipulations are required.

The principle of connection in WAGO terminals is based on the use of isolated spring clamps. The connectors may have a different design for different numbers and types of wires.

WAGO terminals are designed for stranded wires and flexible wires. Using the terminals, the copper and aluminum wires are connected in a matter of minutes. However, spring contacts with a long daily load can lose their original properties.

Thus, using the above methods of connecting the wires, it is possible to carry out their further reliable operation.

Petrovich's advice

In order to select the required conductor, you need to determine its cross section, as well as the number of current-carrying conductors.

Pay attention to the nominal voltage of the wire, which must be not less than the voltage of the electrical network.

Choose the material for the manufacture of the cable, taking into account its subsequent replacement. In practice, aluminum wires can in some cases be replaced by copper wires. On the contrary, unfortunately, it does not always work. But you can already connect aluminum and copper wires with your own hands!