The dining table by right occupies the main place in any kitchen. It is cooked, food is taken for him, a family gathers at the dinner table. This piece of furniture is intensively exploited and is constantly in the center of attention. Make the most durable and high-quality dining table - a very real task, even for inexperienced carpentry people. The main thing is to correctly and consistently perform all operations and pick up good material. Below we will consider the technology of making a kitchen table with our own hands, how to make a table step by step and what materials.

Content

Kitchen table from solid wood

Dining table from solid wood. This, as they say "classics". Natural wood is a material widely used by carpenters for making any furniture, including kitchen furniture. It is a beautiful, durable, environmentally friendly material. For a kitchen table, solid hardwoods are best suited: oak, ash, acacia. However, in the absence of such, you can use coniferous species, but the furniture made of them will not last long, as coniferous rocks do not differ by strength.

Any product made of natural wood needs regular care and restoration. In addition, the tree does not like moisture and temperature changes - under their influence the product can crack and deform.

Glass. The main problem in this case is the complexity of processing the material. In addition, not every glass can be used in the manufacture of furniture. For this purpose, only a fat, thick glass is suitable. To process such material in house conditions it is impossible, so it is necessary to buy a ready glass table-top.

Do not forget about the sheet materials that are used in the manufacture of furniture - chipboard and MDF. They are inexpensive, but the furniture made of them looks very ordinary, and is relatively short-lived.

Dining table: the optimal size, useful tips

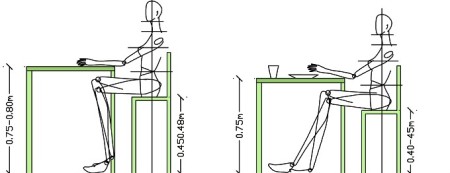

The size of the kitchen furniture, including the table, depends, first of all, on the area of the kitchen area, and the place in which the table will be located. It is generally believed that a person will feel more or less comfortable if his personal zone will be at least 70 cm, and in a radius of 35-40 cm there will be no one. Thus, a kitchen table measuring 90x90 cm or 100x100 cm is fully suitable for a family of four. Of course, such a table should not stand against the wall, so that everyone will sit down on his side.

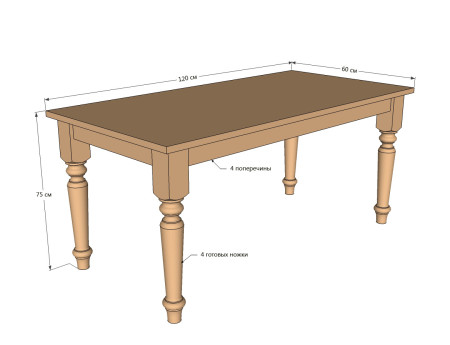

If the kitchen is small, and you can not set the table in the middle, then in this case the optimal dimensions will be as follows: 120x75 cm or 120x80 cm. For this table two people will sit on the long side and two on the short sides.

When the dimensions of the kitchen allow, you can and even need to install a large dining table, the length of which can exceed 160 cm. The dimensions of such tables are often 160x90 cm or 180x90 cm. Free space along the long sides of the table is enough not only for free placement of all family members , but also for several guests.

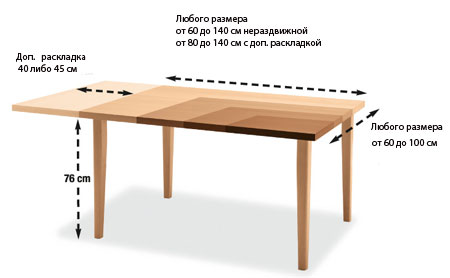

But what about tenants with small kitchens? For such premises, small sliding tables and transformer tables are perfect. Sliding tables have one or more inserts, which increase the surface of the countertop by 40-50 cm minimum. Inserts are located inside the table or are hidden in a special niche. In the unfolded state, such a table can have a length up to 3-meters. This is quite enough to accommodate all the guests who will fit in the apartment. When folded, this table does not take more than 120-180 cm.

As for the height of the dining table, then 70 cm is the optimal size. This figure is not mandatory and can vary depending on the growth of family members in greater or lesser degree.

When calculating the dimensions of the future dining table, you need to focus on the space allocated for it. After everyone sits down at the table, there should be enough free space around him for free movement, so that no one inconveniences it.

Table top for dining table

This element can be made of both solid wood, (glued board of boards), and chipboard or glass. Of course, that the table, made entirely of natural wood, looks very presentable and exquisite, than products from cheap sheet materials can not boast. In addition, the ends of table tops from sheet materials must be edged.

For this purpose, the material cut must be ideal. To make such a cut of the house without special equipment is impossible, so sawing the chipboard must be ordered from specialists. Turn the table tops best with a PVC tape or melamine tape. PVC tape in this regard is more preferable, since the edges of melamine tape are rather sharp, they can spoil clothes and cause small unpleasant cuts.

The thickness of the table top should exceed 2.5 cm. It is better if it will be 3-3.5 cm. If a sheet material with a thickness of less than 2 cm is used for manufacturing the table top, it must be strengthened with the help of a so-called false countertop made of plywood.

Forms of dining tables

A round kitchen dining table is an option, as they say, for an amateur. The main problem is that the round table, oddly enough, requires more space than square or rectangular. It can not be installed in a corner and moved to the wall. The round table is suitable for a dining room or large spacious kitchen, where it can be placed in the center of the room. For small kitchens, it does not fit.

If you decide to make a round kitchen table, then you can experiment with the support a little. For example, to make one massive leg or several supports thinner. Usually round tables for better stability are completed with four legs, which are at a distance of 10-15 cm from the edge of the countertop.

Oval kitchen table can have different sizes - from a small, almost child's table for a tiny kitchenette, to huge products occupying the center of the room. Usually, oval-shaped kitchen tables are large and medium in size, since they fit well in an ordinary city apartment and can comfortably accommodate a large number of guests.

Sliding dining table. Such tables, for which you can seat a large number of guests, can be placed in a separate category. Their shape can be different: round, oval, square, rectangular, etc. The most popular are rectangular and oval models. In terms of self-manufacturing, the rectangular table is slightly simpler than the oval, since it is not necessary to round the corners of the countertop.

Sliding mechanisms can be different. For example, old, "soviet" products did not have roller guide elements. Such a table had to be laid out, making considerable efforts, since the wooden parts were rubbing together. If such a table stood folded for a long time, it was very difficult to push it apart.

Modern products are equipped with special rolling mechanisms, which greatly facilitate the process of transformation and prevent damage to parts. And the surface of the table. All the necessary parts for the manufacture of the sliding mechanism can be purchased in specialized stores.

As for additional inserts-sections of the sliding table, in the folded state of the table, they can be stored directly under the countertop. The simplest option is to make for them unpretentious fasteners, in which they will be inserted.

The dining table with glass details - stands on wooden legs, but has a glass countertop. Such a table is perfect for kitchens in the style of hi-tech or minimalism. Sometimes the top of the glass can be installed on a wooden frame or a wooden countertop with holes. In any case, the product looks very modern and beautiful. In addition, the glass top does not require a protective coating.

The worktop should be made of tempered glass. Such a product is resistant to impact, it is much stronger than wood and the surface of such a table top is very hard to scratch. The legs to the glass table top are fixed with the help of special elements. If you order a finished countertop, then make such a dining table is easy.

Wooden table-transformer. Such tables belong to a special category. In the folded state they represent a small neat little bedside table. It can be put in a corner, near the wall, and it will take only 50-60 cm of space. In the unfolded state, 10-15 people can be freely seated for such a table.

The top cover is attached using special loops. The most common form of transformer tables is rectangular, and round products are also popular.

Dining table with your hands step by step

In order to independently produce furniture, you must have your own workshop, or at least a free garage, as it is impossible to do this in an apartment because of dust and debris. First of all, you need to draw a sketch of the future product on paper or in a computer, all the components of the table, specify the exact dimensions. Sawing materials can be ordered in the workshop, they can also make chiseled legs for the table.

Consider the process of making one of the simplest dining tables.

The following tools and materials will be needed:

• Hacksaw for wood, electric jigsaw.

• Electric drill or screwdriver.

• Milling machine.

• Electric shank.

• Brush for applying varnish or paint.

• Fasteners.

• Sanding machine or sandpaper.

• Lacquer or paint.

• Board thickness of 2 cm.

• Furniture shield.

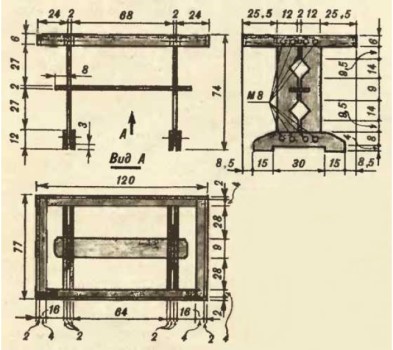

First of all, we cut out all the necessary details according to the sketch. In our case, the table will stand on the simplest straight legs. The legs will have cutouts that are very simple to make with a jigsaw, then clean with a sandpaper or sanding machine and make a chamfer.

The legs for the kitchen table, as can be seen on the drawings, represent two horizontal supports for the countertop, and two vertical elements (legs-racks). All parts are connected with bolts with a cross section of 8 mm. Bolts must be fastened through, on the other hand a nut is screwed. The assembly of the construction starts from the bottom, first one vertical leg is attached, then the second one. Then a special longitudinal board-jumper is mounted in the previously made groove between the stand legs. It is fixed with vertical elements of the feet.

Then you can proceed to fix the countertop. To do this, the finished furniture board is placed in the place where you need to fix the vertical elements of the legs and mount the horizontal stiffeners. These elements should be the same length as the table top. From above it is possible to build flanging from small wooden brusochkov. The flanging to the table top through the stiffeners is attached to the table top by several screws.

First of all, the flanges are attached to the long sides of the countertop, after which the bars are installed on the narrow sides. After that, there is free space between the bars and the table top, which does not look very attractive. It can be hidden with a small decorative strip. It is fastened with dowels. Holes for them do in advance.

The dowels are small wooden cylinders, which are also called nagels. They are inserted into the holes of the flanges, pre-dipped in the glue. Further on dowels, a wooden bar is inserted, after which the table top can be considered ready. It remains only to attach the legs to it. For this, you can use the same bolts as for attaching vertical racks to horizontal supports. Holes for the legs should also be prepared in advance.

This table design turned out to be dismountable - after the feast it can be easily disassembled, untwisted bolts and hidden in a pantry or on the mezzanine. Below you can see the video, which clearly shows how to make the table step by step.