Modern laminate flooring is relevant and in demand. The budget category of coatings, and laminate is classified exactly in this category, is widely used for flooring, wall finishing and furniture. More recently, the craftsmen who made the styling and finishing of the material were valued, like tilers-tiles. But times are changing, and the experience gained by compatriots in the world gives their results. It is sufficient to prepare the substrate carefully for laying. How to do this? Useful advice to your attention.

Content

Preparing the floor for what to do

It is known that the flooring with a laminate is considered to be the most demanded and deserving type of construction measures. The final result is a well-developed technology for creating flooring depends on the quality of the preparation of the floor.

There are several ways to finish the laminate on the concrete floor: using a crate and a substrate, equaling the floor surface with a double concrete screed or a self-leveling mixture.

Enlarged technology of floor preparation consists of the stages:

- dismantling of an existing old coating

- cleaning and removal of floor defects

- control surface measurement for gradient and clearance

- flooring (laying) of the substrate, sheet material or the creation of a screed.

The final stage of finishing is laying the laminate panels. Recall that the permissible value of the floor height difference should not exceed 2 mm / m2.

Helpful Tips

According to experts, laminate flooring is considered a universal floor material, the installation of which is possible on any surface. However, to ensure the durability of the operation and exclude subsequent repairs is possible only on the concrete surface.

The quality of the preparation of the concrete floor determines the choice of the class of floor covering, especially since a certain type of laminate, for example, vinyl, allows you to lay on the adhesive composition. Laying a laminate on a wooden floor will entail additional costs for preparing or replacing the existing roughing floor. However, it is not difficult to solve the issue of choosing a material.

What material should I use when finishing a concrete floor for a laminate?

substrates

The simplest way to prepare a concrete substrate for a laminate is to use roll or sheet artificial substrates, standard or reinforced with a layer of foil, represented by isolon, isopenol, heat-fleex, filmex and other gas-filled polymer structures.

Laying of the substrate is carried out on a prepared (cleaned) concrete base and fasten the joints of the strips with building tape.

As a laminate substrate, a material with a characteristic profile with troughs and heights is used on the warm floor. Substrates are considered an inexpensive option for preparation of the substrate, providing repair and replacement if necessary.

Screed, consisting of a basic and leveling layer, is a labor-intensive preparatory measure.

creation of double ties

It is advisable to produce the screed in the leveling mixture in the case of a drop in the base heights of more than 3 mm / m² using lighthouses.

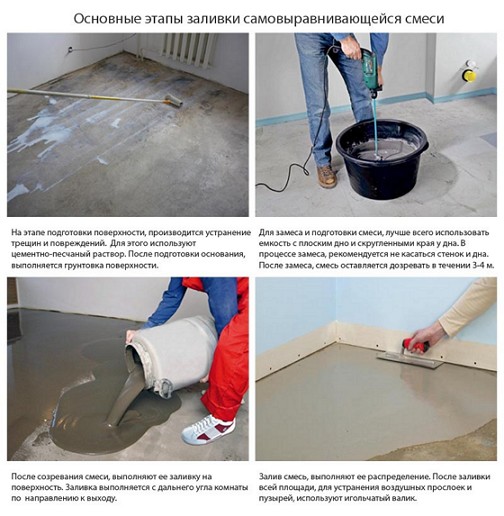

The technology of leveling by filling floors or self-leveling mixtures is as follows:

Base layer

- perimeter placement of damping tape room

- priming of concrete base with special composition

- marking of walls for placement of screed

- accommodation of beacons on rails and mortar slides

- filling with a working solution of the base layer with a thickness of 20-40 mm

- adjustment of the level of the screed to beacons using the rule

- puncturing the working layer of the screed with a needle roller

- hardening and setting of the solution

- the removal of beacons and the filling of holes with a solution mixture

Leveling layer

- application of the second leveling layer from the solution mixture with a thickness of 0.6-0.8 mm

- laying of laminate panels after hardening of the second layer.

The technology of double screed is labor-intensive. The time of creation depends on the speed of setting and hardening of the solution. But this technology is able to fully provide an excellent quality of the working surface under the coating.

Helpful Tips

We will suggest that the composition of the preparation of the working solution for the screed includes: crushed stone, sand and cement powder of loose consistency with the weight of loose in the ratio 1500/1400/1300 m3 / kg. In practice, this ratio will look like this:

The screed volume on the area of 35 m2 is 0,44m3х1300 / 1400 kg / m3 with a total mass of cement 572 kg (10 bags of 50 kg). It is important to remember that the volume of dry cement composition during the preparation of the solution decreases in volume. At the outlet for the preparation of 1 m3, the volume of the solution is 0.6-0.7 m3.

How to level the floor with a screed, shown in the video.

The preparation of a wooden floor is fundamentally different from the construction of a screed and consists of laying a wooden crate and leveling with sheets of plywood 10 mm thick.

prepare the wooden floor for a laminate

To lay the laminate on a wooden base, use a scheme of floating floor, on which the cover is freely located on the rough floor. The current technology of preparation allows you to dispense with glutinous formulations, providing ventilation and aeration of the coating.

Stages of foundation preparation

- revision of the state of the wooden foundation in order to clarify the degree of wear of the structure

- making dismantling of old and unusable boards, sections of logs and beams

- we make replacement of elements, having preliminary processed boards and logs with fire retardant

- the replaced wooden cover is plated.

Keep in mind that the right length of screws for fastening and the power of the screwdriver will facilitate the laying process.

Own manual preparation of the wooden floor is shown in the video.

features of laying a laminate on a concrete foundation

Laying of the laminate panels starts from the far corner of the room, after preliminary spreading the substrate. The first panel should not be closely adjacent to the wall, leaving a technological gap of 1-1.5 cm using spacers along the length of the abutment and at the ends.

The first element of the second row is applied immediately, having opened the panel taking into account the fitting of the open end lock.

How to make laminate flooring learn from article.