The market was captured by furniture made of fiberboard and chipboard.

With total Soviet deficit furniture was bought once and for life. Of course, if the furniture is old, made of natural wood, it serves a long time, is not afraid of moving. But modern furniture from fiberboard and chipboard does not stand up to any criticism, to be exact - no moves. We suggest to return to the grandmother's furniture sets and make them yourself. The best advice is to use video to make furniture. In modern Internet search engines, you can easily find educational video lessons on furniture manufacturing.

Content

General information and principles of furniture production from wood

We offer to facilitate the work with natural wood using the methods of making furniture under the old days.

But you need to consider the style of arrangement of your house.

If the house is made in a classical style, then the furniture for "old times" will perfectly fit into your design.

In carrying out this work, the following principles must be adhered to:

-all parts must be made only of wood or in extreme cases from natural plywood;

- Use furniture fittings old or artificially aged to decorate furniture. To do this, study the catalogs of antique furniture, dig into the directories and look for something on the Internet;

-Fastly fits into the antique furniture elements of the carving. The thread is made on a separate piece, then, using carpentry glue, the thread is fastened to the furniture array.

The result of this work is a unique piece in a piece.

How to make a wooden table under the antiquity

Master the skills of a master cabinet maker, best from the manufacture of the simplest.

Such a simple element can be considered a table, since it is very simple to make it.

The main thing is that the table is beautiful, all surfaces should be polished perfectly.

The following materials and tools are required for the job:

-boards of excellent quality, without knots;

-Wooden timber;

- woodworking machine or plane and jointer;

-knife for wood;

- screwdriver;

-shirts, self-tapping screws;

-sandpaper;

- a grinder and a grinding wheel;

- a stove;

-lac for wood.

In the process of work, initially, must be carefully processed, ostrugans and fit to the height of the board for the front surface of the table.

To prevent curvature of the finished product, the boards must be well dried under the press.

Depending on the size of the proposed table, we make a wooden box from the timber.

From the wrong side, attach the cover to the wooden box.

So you got the top of the table.

The next stage is the production of legs from a square square bar.

The legs should be perfectly adjusted to fit, otherwise the table will stagger.

The legs are fixed in the corners of the wooden frame.

Fasten the legs with metal corners, wooden studs or chopped spikes.

Use joinery glue.

The next task is to create a beautiful table under the old days.

Keep in mind that all wooden parts must have a very smooth surface.

With the help of stain, even the simplest wood can turn out very attractive in appearance.

Having made the final conclusion about the color of the future product, cover the surface of the tree with stain of the desired color.

After the stain dries, treat the surface with fine sandpaper.

As a result of your work, you will get a beautiful wood texture.

The next step in your work is to cover the table with a colorless varnish.

To work with varnish, use a cotton swab wrapped with gauze, and not a brush.

The varnish is applied by light sliding movements. It is best to apply 2-3 coats of lacquer.

In the same way you will make stools.

By principle - a stool is a small table.

Working with the table, you should understand that if the table is made for an apartment, then the design should be elegant, the lid is not particularly thick, the legs are corresponding to the lid and observe stability.

If the table is made for a street gazebo, the countertop and table legs should be made to be massive.

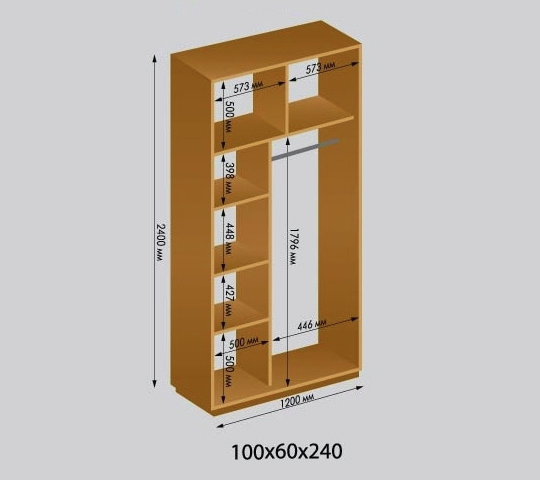

How to make a cupboard antique

The cabinet with its own hands is also quite simple.

Although, its dimensions are larger than the table and may need an assistant.

The main task is to strictly maintain the vertical and horizontal, the angles must be strictly 90 *.

The simplest option is to make a cabinet box from wooden bars.

Walls, ceilings and doors can be made from thick plywood.

If it is supposed to transport furniture, then the cabinet can be made collapsible.

To do this, all fastenings are made on bolts.

The main task is the box, which must be firm and stable. You can practice and make a wardrobe for the loggia.

Such a cabinet is made easier, since the wall is the support of the cabinet, the bars are fixed to the wall at a distance from each other in accordance with the width of the cabinet.

To these bars are attached at an angle of 90 * short bars in accordance with the depth of the cabinet, etc. All this can be seen in the video.