To the choice of flooring in the apartment, we always approach meticulously: we are always worried about practicality, durability and respectable appearance. In this case, you can not make mistakes, because lamination with your own hands is not often done.

Content

A cheap and practical alternative to parquet or composite floors is laminate flooring. What types of laminate are currently available?

Types of laminate

Types of laminate cover are distinguished by manufacturing technology and application. Therefore, the laminate is divided for use and application in residential and public premises. According to the type of load coatings are divided into a high degree, medium and light. For the kitchen and the hallway, the cover is used with a high degree of load, for the living rooms with medium and for the bedrooms, preference is given to an easy degree of load. When choosing a laminate coating, it is necessary to pay attention to the manufacturer's designations on the package.

How to properly and correctly make a choice of laminate flooring will help you video.

The process of laying laminate in the apartment with their own hands consists of the stages:

- preparatory

- laying of the substrate

- laying laminate flooring

- installation of skirting boards.

Before you start laying a laminate flooring, you need to choose a way of laying.

Methods of laying the coating

Numerous methods of laying a laminate are oriented to lighting a room or a room and depend on the structure and pattern of the slabs, as well as the type of locks. The Click system completely changed the technology of laying and operation of the coatings and our understanding of the ways of laying.

Now for lock technology, the assembly is done without the use of any special tools and glue. Plate slabs are stuck together along the long side at an angle of 40 degrees, easy pressing, click! And the joint strength is secured for a long time, if not forever. Without the glue technology "spike" - "groove" mechanically clicks them together. Now the laying of the laminate has become simple, like assembling a colorful children's puzzle.

Separate the following types and methods of laying the coating:

- straight laying along the line of light

- laying across the light line

- diagonal styling.

A detailed instruction of the laminate locks will allow to determine the preferred method of laying according to two generally known methods.

To find out more about the types of locks for laminate flooring, see the video.

Direct laying along the line of light the most popular and acceptable. Laying is done along the line of light parallel to the length of the wall of the room and starts from the door. The illusion of the integrity of the coating is created by the fact that when the light falls, the working seams between the panels do not create or cast a shadow. With such a known method of laying, the consumption for cutting panels is up to 6%.

In the method laying across the line of light The floor panels are perpendicular to the long wall of the room along the door. This method is most preferable for long rooms or corridors, because this creates a significant width effect.

Diagonal laying of laminate the most laborious, and therefore the most expensive. The preference for this method of laying will be justified in the case where your spectacular matte or shiny laminate will not be covered with carpets or cumbersome furniture. The effect of laminate panels in this case will shine in all its glory. However, when trimming laminate panels, the material consumption increases and can be 15%.

The value of the substrate when laying the laminate

The meaning of the substrate can be said for a long time and convincingly. Yes, we can not hide that the substrate is simply necessary when laying a laminate coating.

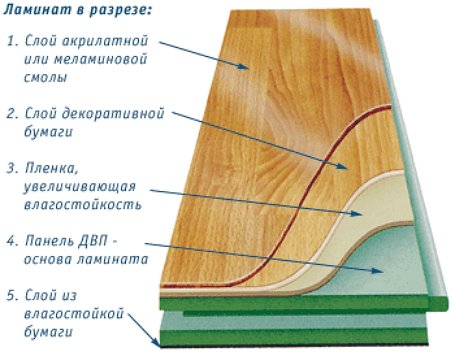

The base for laying the laminate should have a flat surface, so the working floor (concrete surface and tile) is covered with a waterproof material - a substrate. It is the substrate that can provide amortization of the floor, sound absorption and thermal insulation. The most demanded is a substrate made of polyethylene foam and cork. However, if the laminate is laid on a wooden floor, then the substrate of synthetic materials is simply not needed, it will be replaced by lags.

After purchasing and transporting the laminate panels, the boards should lie in the packed state in the middle of the room. This is necessary to adapt the laminate to the temperature regime of the subsequent laying. A comfortable temperature mode of laying is the temperature of air plus 18-20 degrees, and the relative humidity of the room is 70 percent. By the way, in each pack of laminate there are detailed rules of laying.

Laying the laminate yourself

In order to produce laminate flooring by one's own hands, it is necessary to carefully perform the stages of preparation and installation using the quality materials chosen and purchased for this purpose.

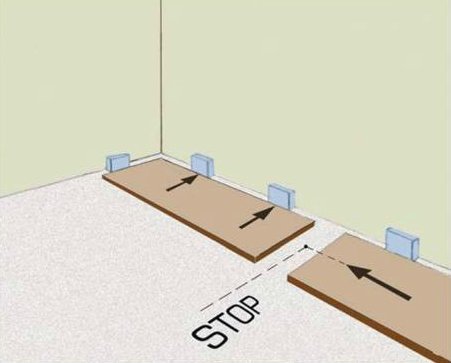

Laying the laminate begins with the installation of the first two boards for the first row. In this case, it is necessary to install special spacer wedges that will provide a technological gap between the laminate panel and the wall. This distance is 7-15 mm. Such gaps are necessary for expansion or compression of laminate panels. The laminate panel is fitted with a lock "on yourself", providing easy operation and snapping. In this way, the first row is laid completely in the width of the room. After the formation of 1 row of coating, 2 rows are laid in half of the board.

This is the common type of installation, which ensures the correct distribution of pressure between the panels in a common array. The panel of the second row is then inserted into the lock at an angle of 40 degrees, slightly pressed down and slightly raised before the final snapping. At the ends of the panel does not click, but only a little trying. When the short side is laid, the longest is brought as much as possible to the laid floor. Then the long side is lifted and pressed in the area of the joint before snapping.

When working, it is necessary to monitor the position of the spreading wedges that must remain in place. Installation of the last extreme, abutting panel to the wall, is made using a metal clamp, which will resemble the panel in place. This is how the laminate is laid in series.

To learn the rules and secrets of the "right" styling thoroughly, look at the proposed video from professionals.