Bath - the building is special. When building a bath it is necessary to choose the right materials for interior decoration, which can withstand constant changes in temperature and humidity. Particular attention should be paid to the doors in the steam room. Our publication on how to choose the door for the steam room, how to properly install them, and how and what to make the doors in the steam room with their own hands.

Content

Doors for baths and saunas: constructions and types

In any door bath there are at least two: the front door and the door to the steam room. Of course, the more rooms inside the bath, the more doors you need - from the vestibule to the dressing room, from the dressing room to the steam room, to the pool, to the rest room, etc.

Choosing the doors for the bath, you need to take into account a lot of things: the area of the room of the steam room, the type of wood that the room is trimmed, the capacity and dimensions of the oven, etc. And there's plenty to choose from in our time-free time.

Manufacturers offer several basic types of doors for baths and saunas:

- Solid door of solid wood.

- Glass door.

- Combined - a wooden door with partial glazing.

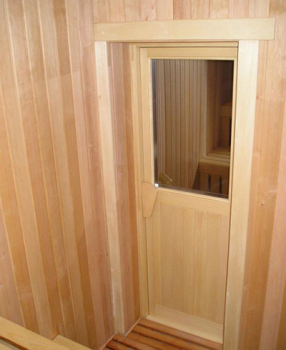

Glass doors are usually installed in saunas. For a classical Russian bath the wooden or combined door is the best choice.

Now it is possible to buy or order really beautiful doors decorated in the most intricate way, and it is possible to stay on the variant more modestly - with a flat solid surface. As for the building material, the doors are usually made of linden, aspen, oak, cedar, and spruce. Glass doors are made of heat-resistant impact-resistant glass with a thickness of at least 8 millimeters. The glass door does not react at all to changes in temperature and humidity. The door glass can be completely transparent, matte, corrugated, decorated with a pattern or pattern. You can pick up a glass of almost any color - under the interior of the room.

The basic requirements for the doors to the steam room

The main function of the doors leading to the room of the steam room is to effectively keep the heat. Therefore, when making a door into a steam room, the dimensions are chosen somewhat smaller than that of a conventional door. As a rule, this applies only to the entrance doors and the doors to the therma. For other rooms, doors are made of ordinary dimensions.

To keep the door in the steam room better kept the heat, make a fairly high threshold - about 15 centimeters. The dimensions of the door itself are usually 1.6x1.8 m. Of course, the dimensions given here are not mandatory, everything is individual here.

The door to the thermae should open only to the outside. Many developers provide direct exit from the steam room in the shower or the pool. In this case, to set a high threshold is not necessary, you can even make a small gap under the door a few centimeters. Through it, excess steam and moisture from the steam room will be drawn. In addition, the door to the washing room is installed in a door frame with a small gap - about 0.5 centimeters, as the door will swell from moisture, and can jam.

It is not recommended to install double-wing door constructions in a bath. They will be appropriate only if the bath is heated in the old way - "in black." In this case, the double-leaf door will help quickly get rid of excess smoke in the room, and at the same time reduce the heat loss to a minimum.

To properly choose the material for the door for your bath, you need to follow several basic criteria when choosing:

- Durability.

- Security.

- Attractive appearance.

- Operating conditions of the door.

Due to modern methods of wood processing it is possible to increase the service life of wood several times. But still, it is impossible to completely protect the wooden door from the aggressive effects of moisture and temperature. Therefore, when choosing a door to a therma, one should realize that eventually it will inevitably deform and gradually break down. In this regard, the glass door will be preferable.

If we talk about security, then not everything is clear. For example, a glass door allows you to constantly monitor the situation in the steam room, this is important, especially if there are children. But on the other hand, with a strong impact, the glass will break, and the wooden door will withstand such a test without any consequences. True, the doors to the steam room are glass, breaking, do not give sharp shards.

Fittings for doors in steam room

When choosing fittings, choose materials with low thermal conductivity and high resistance to moisture. In no case can be installed on the door to the steam room metal latch and handle - they quickly deteriorate from high humidity, and can cause serious burns. These parts are made mainly of wood, less often - plastic.

Hinges for the door to the steam room is better to buy from brass, if such can not be found, then the usual metal loops before installation should be carefully treated with high-quality anti-corrosion paint. Since the doors will open outwards, it's almost impossible to earn an accidental burn from touching the hinges.

The door to the steam room with your own hands

After the materials have been selected, and you have decided on the design of the future door, you can proceed with its manufacture. This work requires the master some experience and skills in working with power tools, accuracy, accuracy and understanding of the actions performed. Of course, a complete newcomer in this matter will seem a little difficult, but this is only a matter of experience. If desired, you can buy some inexpensive pine boards and pre-practice.

For a Russian bath, the most suitable is a blind wooden door, therefore, we consider the manufacturing process using the example of this design.

The following materials will be required:

- Board width of 5 centimeters, 3 centimeters thick, punctuated.

- Strapping bar 6 x 8 centimeters.

- Wood paneling 12x9 millimeters.

- Brass or metal hinges - 3 pieces.

- Furniture pins and wood screws.

Instruments:

- Circular electric or manual saw.

- Frizmashinka with a set of milling cutters.

- Electric drill or screwdriver.

- A hammer.

- Two or three clamps.

- Roulette, building level, calipers.

Manufacturing of doors in the steam room begins with the canvas. We do the following:

We punch the board to the required length. The main thing is to calculate everything correctly, since the height of the door will include not only the height of the canvas, but also the bars of the strapping. Therefore, cut the board with the calculation of the thickness of the beam at the top and bottom. For example, the height of the door leaf should be 1.5 meters. We subtract from the length of 25 millimeters at the top and bottom - they will be hidden in the harness in the form of a spike.

At one board we cut off the thorn, we fuguem all boards - it is necessary to remove from a surface some millimeters that all boards turned out equal and with a smooth surface, thickness approximately in 25-26 millimeters.

After that you can start to collect the canvas. First we make a rough assembly - we insert the boards with spikes into the groove as tight as possible.

Perhaps the canvas is wider than the required size, this is normal. To get the right width of the canvas, we pull out the first and last boards, and cut them along to the desired size. The main thing is not to cut the thorn and groove. After that, you can do the final assembly of the door leaf. On a flat surface, lay out the boards and collect them, having previously spiked the spikes with joinery glue. Sometimes it is recommended to use PVA glue, but it is destroyed by moisture, it is better to use a universal polymer-based adhesive, for example, a dragon. For a more dense connection of the boards, we punch each wooden kyanik or hammer, substituting a wooden block.

After that, the canvas should dry for a few days. In order not to do so, the door leaf must be securely fixed-for this you need to fill two longitudinal strips on a workbench, a table or any other level surface, and put a cloth between them. Between the slats and the canvas we drive wood wedges, we put a sheet of plywood or chipboard on top and press the cloth firmly against the surface with clamps.

As soon as the door dries, check the surface for defects. We remove the unevenness of the plane, we fill up the crevices and grooves with a mixture of glue with sawdust or putty.

strapping and fittings for doors to the steam room

In order not to lose time, while the canvas dries, you can start making hardware - a bolt, handles, and also make a harness. For the manufacture of strapping the prepared bars we cut to the desired size. The length of the vertical bars of the binding should be equal to the length of the web. Horizontal bars should be smaller. For example, if the width of the door is 70 centimeters, then we cut the bars by 7 centimeters less - 63 centimeters.

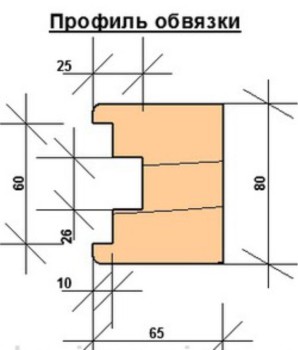

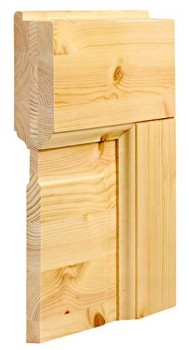

Further in the longitudinal bars you need to make a stepped groove. We take a milling machine with an end mill. We choose a groove with a width of 26 millimeters and a depth of 10 millimeters. Directly on top of it we make a wide and shallow groove - a width of 50 millimeters and a depth of 10 millimeters.

Thus, a canvas is placed in the first, deeper groove, and in the second, a shallower one, which will be trimmed with a cloth. On the cross bars, using a milling machine, we make a stepped spike, corresponding to the dimensions of the groove.

Next, you can collect the bundle box, carefully check all corners with a square. If there is a need, we correct the groove with grooves in order to obtain an exact even angle.

For the manufacture of bolts and door handles, you can take the remains of bars or boards or buy blanks. The most simple handle can be done with a conventional hacksaw.

You just need to put a blank on the workpiece and cut out the handle. The bolt is also easy to make - two staples and a bolt tongue are cut out, which will move freely in the brackets.

final assembly and cladding of the door into the steam room

After the end of the assembly of the cloth and strapping, it remains to cover the door into the steam room with the lining and make the door frame. The finished fabric is treated with compositions from putrefaction, fungus and mold. If the door is from aspen, then it is not necessary. On the canvas, we draw a contour for the lining with an indentation from the edge of 15 millimeters. We cut the lining up to the desired length and fasten the laths to the canvas with small nails or screws, which must be hidden in the slots of the lining.

Next, we set the bandage for the fabric.

Pre-prepared bars are also treated with antiseptics, first set vertical bars, then horizontal, we adjust them with a kyanik or hammer. The grooves of the beams of the straps before the installation are also treated with glue. The lower beam is not glued to the glue - if the door needs to be repaired, it should be easily removed.

In the ends of the bars screw the screws - two pieces in horizontal bars, and three - in vertical.

The final stage of the assembly of the doors into the steam room is the installation of the handle and the bolt. At the end of the wooden handle and staples we drill a hole about 4 cm deep. We take a drill with a smaller diameter, apply the handle to the door in the right place, and make a through hole, partially capturing the fabric. After this, we screw the self-tapping screw of the appropriate length to the stop. He must enter the canvas to a depth of at least 2.5 centimeters. In a wide hole in the handle we hammer a wooden stopper, cut it off unnecessarily and sand it with sandpaper. Brackets for bolts are fastened in the same way.

Once the door leaf is ready, proceed to assemble the door frame. For its production we need bars measuring 10x10 centimeters. Cut them to the right size, at the ends choose a quarter frezhaashinka. The depth of the quarter is done with a margin of 5 millimeters to expand the door.

The upper bar should be smaller than the width of the door frame, and the height of the threshold should be about 15 centimeters. To connect the beams of the box, on the edges of the racks at the top and bottom we cut out grooves, at the edges of the threshold and the upper bar - thorns. We collect the box and check the corners. If necessary, we correct the groove, then we process the box with antiseptic, and proceed to install the door into the steam room.

Installing the door in the steam room

The installation of the door begins with the device grooves under the box in the doorway. The size of the grooves is made with a margin of about one and a half centimeters more. This is necessary in order that, if necessary, you can fix the box in the grooves and fix it with wedges. We put the box in the grooves, but do not forget that the door opens outward.

We drill the holes for the dowels in the doorway, then we start the upper horizontal bar of the box, prop it with vertical posts, lay the threshold. Check the vertical level of the structure. In the gaps between the doorway and the box, drive in the wedges, attach the box to the wall with screws, screwing them into pre-prepared holes with dowels. After the box is securely fixed, install the hinges. The upper loop should be located at a height of about 25 cm from the top edge of the canvas, the middle - about 50 centimeters from the top edge, the lower one - 25 centimeters from the bottom edge of the canvas. The dimensions of the indentation of the loops are not chosen by chance - this uneven distribution will prevent the door leaf from skewing.

After that, it remains only to hang the canvas, to beat around the perimeter of the canvas a roller of felt or other natural sealant, and also to fill up all the cracks in the gap between the box and the wall.

There are quite a few ways to make the door to the steam room with your own hands. Each owner of his own bath can choose the right one for himself. The manufacture of the door, especially in the room of the steam room, does not differ in simplicity, but on what doors the steam room will be installed, the comfort and even the security of the people resting there largely depends, therefore, the choice and manufacture of the door must be treated responsibly. But the result will be worth the effort.

Of course, in such a rather complicated work, it is unlikely to do without mistakes, but true lovers do not be afraid to do this with their own hands.