An interesting modern building invention are roofing sandwich panels. The use of this material in the construction or reconstruction of buildings and structures, both residential and commercial, significantly accelerates the timing of the project's commissioning. These roof panels have impeccable technical characteristics, and besides, they are convenient and easy to install. The main advantage of these panels is their multi-layer construction. Unlike obsolete types of roofing materials, this does not require the installation of auxiliary insulation, because already in itself is a complete roofing system.

Content

- 1 What are Sandwich Panels?

- 2 What sizes can sandwich pvc panels have?

- 3 Main advantages of sandwich panels

- 4 What measures can compensate for the shortcomings of sandwich panels

- 5 Installation of roofing sandwich panels

- 6 Fastening of sandwich panels

- 7 Sandwich panels, roofing, price and recommendations for the choice of material

What are Sandwich Panels?

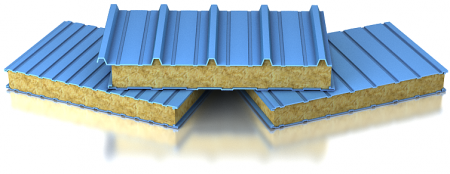

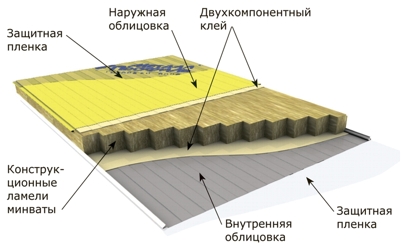

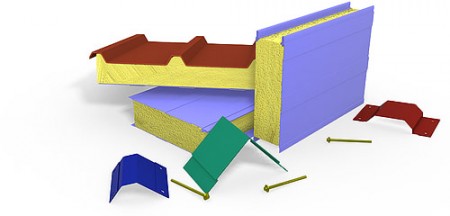

Basically, sandwich panels look like a three-layer structure. The layers on the outside are made of various protective hard materials. A layer in the middle is a heater. In most cases, the outer layers of these panels are made from OSB-boards. There are options when one side is made of a profiled steel sheet. But for overlapping roofs, panels with external layers of OSB-boards with increased waterproofing are also used.

A heater in this construction can be:

- fiberglass,

- expanded polystyrene,

- basalt fiber,

- polyurethane foam.

In general, foam polystyrene and polyurethane foam are used as insulation, the materials do not absorb moisture at all. Polyurethane foam is used more often, since it is also fire-resistant.

On the outside of the panels there are skates, approximately 40 mm in height, which increase the rigidity and hardness of the material. More skates are used to organize a watercourse for wastewater.

The outer layer of the steel sheet profile is covered with a polymer composition, which in turn protects the roof from the effects of acid rain, prevents burnout and protects against abrasion.

Firms-manufacturers quite widely represent color scale of sandwich-panels. Most often, traditional blue, brick or white models are bought. It is generally accepted that panels of light shades are less exposed to the harmful effects of the sun.

What sizes can sandwich pvc panels have?

Dimensions of roofing sandwich panels are not similar to the size of other similar building materials. There are two types of panel production: standardized and customized. Standard panels have the following dimensions: width - 1000 mm, length - 1600 mm. The thickness can range from 40 to 160 mm. With custom production, the maximum thickness of the product can be greater than with a standardized one, which is very important for areas with harsh climatic conditions. In the event that there are mansard window, in addition order finishing accessories for the window. The length and width, in this case, can also vary depending on the customer's request.

Main advantages of sandwich panels

Let's recall what the positive qualities of sandwich panels are:

- excellent thermal insulation qualities, which gives a layer of insulation material;

- quick and easy installation and dismantling, in all weather conditions and in a zone with any climate;

- a small weight of the components, which makes it possible to use a lightweight rafter part of the roof;

- immediate replacement of any part if necessary;

- high wind resistance, low susceptibility to changes in the temperature regime, no deformation at high snow pressure;

- a long service life of at least 25 years;

- affordable price of the material, because the sandwich panel is already finished products that do not require additional processing, which makes it possible to reduce the cost of material.

What measures can compensate for the shortcomings of sandwich panels

But, as in everything else, sandwich panels have their drawbacks. The main disadvantage of this building material is that it is airtight. However, this problem can be minimized if the ventilation system is correctly constructed. Formaldehyde and styrene formed in air, when polystyrene and foam is heated in the warm season, is also eliminated. Their negative impact can be reduced if the insulation layer is made of polyurethane foam or mineral wool.

Installation of roofing sandwich panels

Mandatory parameters of the main works:

- gusts of wind not exceeding 9 m / s (due to the small weight and large dimensions of the building material);

- absence of poor visibility (fog), high humidity, precipitation - conditions unacceptable for roofing works;

- the street temperature should not be less than 4 degrees, otherwise, the qualitative execution of the design of joints and the production of compaction will be impossible.

Fastening of sandwich panels

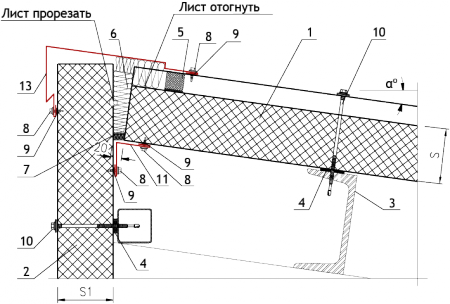

Before the beginning of the work connected with fastening of a roofing material, it is obligatory to read the technical accompanying documentation. It is there that all the necessary information about the purpose, functions and methods of packing the material is fixed. Also in this documentation are recorded information about the manufacturer, type of panels, their number and dimensions, profile type.

In the editing part of the documentation there is information about the modification of the elements of the connection, their number and location. In addition, there are data on the classification of finishes, architecture and the like.

The next step is to check the correct ratio of the roof slope to the parameters specified in the project. It should be remembered that for a roof consisting of one panel, a 5 degree slope is permissible, provided that there are no hatches, dormer windows and rooflights. For a roof consisting of several panels, a slope of 7 degrees and the presence of openings for manholes, windows and so on are permissible.

Now it is necessary to compare the project data on the supporting structure, in other words, the horizontal and vertical dimensions of the runs, rafters and racks. In cases where inconsistencies are found in the geometric data of the supporting structure, they must be immediately corrected. If the installation of the roof is supposed to be done on a structure made of metal, you need to make sure that corrosion does not occur on the metal. If you find them, you should immediately remove them.

Checking the working condition of the tools for measuring work and the tool needed for installation will not be superfluous. In the manual, you can find a detailed scheme and a technological map for fixing sandwich panels, and plus this, data on the safe conduct of work.

Immediately before the start of the installation of the panels, you need to remove dirt and debris from the construction site, and also align it, for better work. Experts advise that when cleaning sandwich panels do not use detergents with abrasive ingredients, alkalis and acids. To ensure that the upper polymer layer of the panel coating is left without flaws and damages, it should not be placed in stiff shoes, nor should it be necessary to put objects that are heavily weighed or have the ability to damage the surface (pierce, scratch, punch, etc. ).

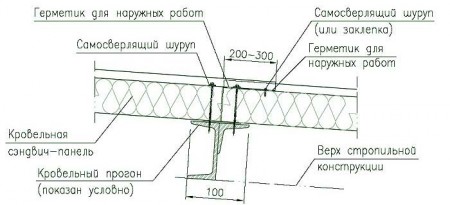

When installing sandwich panels, an electric drill and a screwdriver operating at high speeds are usually used. The structures for the support can be made of a variety of building materials. In this regard, and types of fastening are selected depending on the thickness of the structure. Most often, self-tapping is used for this. In order to choose suitable length, it is necessary to summarize the thickness of the frame, panels, 5 mm stock on the washer, the length of the drill bit.

Self-tapping screws, for fastening sandwich panels, must necessarily be with sealing washers. Such washers are made of elastic materials, so they protect the surface from possible scratches by the metal head while screwing, and also give a one-hundred percent guarantee of tightness in the places of the fasteners.

Fastening of additional necessary fragments is performed with shorter self-tapping screws or rivets. Usually, for fixing the panel more than 6 meters in length, a maximum of 8 screws are used, for 6 meters there will be enough 6 screws, and for fixing the length not exceeding 4 meters, grip 4 pieces of fastening elements.

Sandwich panels, roofing, price and recommendations for the choice of material

Buying in a specialized store a few packages of panels, you need to compare the numbers of all and identify the correspondence between them. In the future, this procedure will help to avoid troubles associated with the mismatch of color shades of the purchased material for overlapping.

If you need to cut sandwich panels, you need to cut them so that they are horizontally the same on both sides. To perform this procedure correctly, you will need a level. Only after the level has been checked all planned lines, it is possible to make a cut of the metal layer, and then the insulation.

The panels of the species under consideration are very susceptible to an increase in temperature. This is because the metal loses its resistance to corrosive changes when heated. Proceeding from this, specialists do not recommend cutting with machines for grinding or plasma cutting. The maximum that can be used, and then, only for a small amount of work - is an electric scissors.

Directly before the fastening of each panel, it is necessary to clean its parts at the joints. Of course, first of all you need to remove the film, which protects the panel from deformation during transportation. The process of film removal is not recommended at low and high temperatures. The film on the sandwich panel should not be exposed to the influence of sunlight and the action of solvents.

The mechanism designed for lifting works will help lift the panel to a height. Most importantly, in the process of raising the material, make maximum efforts to ensure that during the rise and placement on the roof, the top layer of the product is not damaged, and especially if the construction material for overlapping has a length of more than 8 meters - is not deformed. To protect against all sorts of damages are quite suitable: vacuum suckers, located on the mechanical grippers; clamps with gaskets made of rubber or felt and the like.

The price of the sandwich panel is quite acceptable even for construction with a low budget. It depends on several factors:

- type of internal filler, which can be styrene polystyrene or mineral wool,

- from the destination, the wall type or roofing.