The faucet mixer tap is a thing that seems to be inconspicuous, but if it fails, the consequences will be the most unpleasant - the tap will make noise, open and leak badly. The leakage of the closed cock is the very first sign that the crane of the box has worn out, and it's time to fix it or replace it completely. In addition, the crane can produce characteristic rattling and "grinding" sounds. A defective crane of a box can deliver a lot of troubles, which, however, can be quickly and easily eliminated by replacing or repairing the part. Before we talk about how to remove the bucket axle and how it can be repaired, we will consider the features of this part, its varieties, advantages and disadvantages.

Content

Ceramic boom ceramic, device, purpose

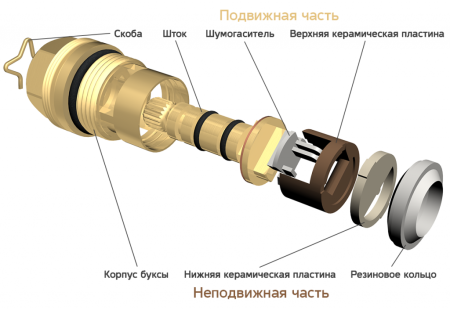

The main difference of this part from the "classic" worm axle crane is that it, as is clear from the name, contains special inserts of ceramics. These elements are directly responsible for the supply of water and its overlap. They are made of cermet - aluminum oxide. The mechanism is quite simple - consists of two plates of ceramics with holes. The aluminum oxide from which the plates are made is a very strong material, so that no scratches remain on the working surface of the elements during operation.

When the tap is turned, the plates converge in the same plane, and an opening is formed through which a flow of water enters, which can be adjusted as needed. The crane with a worm axle must be turned several times in one direction or the other when opening / closing, the ceramic box allows to start and shut off water with one easy movement.

The main disadvantage of cranes with a rubber gasket is frequent breakdowns, as they spin in a few turns with the use of force. As a result, rubber quickly wears out the faucet, starts to "cough", hiss and leak. The principle of operation of the ceramic box crane is to shift the ceramic plates relative to each other. The crane of the box contains two plates - one tightly fixed in the body, the second, a movable plate located inside the rod, which is connected to the handle of the mixer. When the handle is rotated, the stem and plate move to form a hole. When you close the plate diverge, and the water stops flowing.

The service life of the crane is large, but it costs an order of magnitude more than usual, with a rubber gasket. In addition, ceramics do not like hard water with impurities, so it is desirable to install a coarse filter on the water supply.

The mixer with ceramic beech works absolutely noiselessly, which adds comfort to operation. Plates inside the crane can be displaced by 90 or 45 degrees - depending on what force is needed pressure.

How does the crane handle work?

To better imagine all the advantages of the axle crane in comparison with traditional worm cranes, you need to familiarize yourself with its device and the principle of operation.

The main structural elements of ceramic axle box:

• Enclosure.

• Stem retainer.

• The turnstile.

• Top plate.

• Bottom plate.

• Gasket.

The body is made using alloys of non-ferrous metals. Inside the case there is a rubber gasket to ensure tightness. On both sides of the shell there are small slots for water. When buying a crane axle, be sure to pay attention to the length of its body - the dimensions may not fit your mixer. On sale, the ceramic tap is most often found, the dimensions of which are 3 4, 3/8, 1/2 inch. The case of the box is fixed to the stem with a steel lock - when disassembled, it is easy to separate with a conventional screwdriver.

The turnstile is responsible for the operation of the handle of the mixer, it is quite brittle, with strong pressing can break. The upper plate has a hole for connection to the turnstile, as well as a hole for water. In older models of the axle crane, the plate was rotated to a fixed distance, in new models it rotated without restrictions. As mentioned above, the bottom plate must match exactly with the top plate - the correct supply of water depends on this. For this, several additional fixatives are placed on the bottom plate. Both plates are treated with special silicone grease to avoid premature wear.

Insulating gasket for the crane of the box is made of rubber. Its main purpose is to ensure the water flow only between the plates. The gasket is not exposed to loads, therefore its service life is long enough, provided that the water in the water pipe will not contain any corrosive impurities.

So, when you turn the mixer knob, the stem and the pivot shift the top plate - the water starts to flow into the mixing chamber, and from there through the tap to the outside. When the handle is turned in the opposite direction, the plates converge and the water stops flowing.

Buying a mixer, you can choose an already ready design, or buy a ceramic beech and insert it into an old mixer. On sale there are models specially designed for cranes of the old Soviet design. Such axleboxes have a tetrahedral head on the pivot rod. The most common models of cranes to date - with the head-star, which has 12 or 16 faces, without the restriction of rotation.

How to change cocker spigot

It is very simple to do this - only flat screwdrivers and a 0-degree wrench are needed from the tools.

The order of work is as follows:

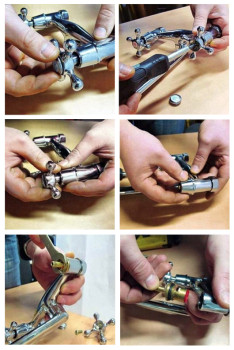

• We remove the flywheel from the crane. To do this, use a screwdriver to break the plastic plug, unscrew the fixing screw, and then access directly to the bush.

• In order to unscrew the axle, in most cases a key is sufficient for "17". Very often the ceramic faucet is supplied with locknuts, which must be loosened with a wrench. The crane with a square head can be turned off with a key to "7", turning the stem counterclockwise. All assembly work is carried out in the reverse order.

Repair faucet beech ceramic, useful tips

replacement gaskets

It should be noted that in some cases only a complete replacement of the axle crane will help, however, if you want and the availability of some experience, you can try to repair it if the damage is not critical.

For repair, you only need a wrench and a screwdriver. With their help, it will not be very difficult to remove the ceramic faucet from the mixer, completely disassemble it, and replace the failed parts. In the process of work, you may need a sealing tape, or a towel with a sealant (Unipak is recommended).

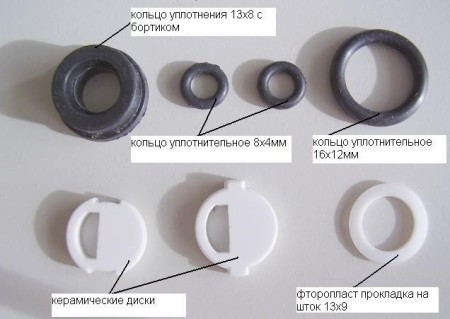

In the overwhelming majority of cases, the gasket of the axle crane leaves the building - as a result, the crane starts leaking. To fix the problem, you will have to purchase a repair kit for the crane of the axlebox, it can be found in almost any market or in a specialized sanitaryware shop. An important point: to the mixers of imported and domestic manufacturers are different sets of repair kits.

The gasket ensures reliable isolation of the box in the mixer, it has the shape of a ring, and is worn on the outer part of the housing. To replace the gasket, there is no need even to remove the axle itself. For a quick repair "in haste" it is enough to seal the structure with a sealant, but this is a temporary measure.

To replace the failed gasket, we perform the following actions:

• Be sure to turn off the water supply to the mixer.

• Using a flat screwdriver, we hook up the plastic cover of the valve.

• Remove the screw and remove the flywheel.

• Remove the upper part of the axle from the socket.

You should have a pipe in your hands, with a rubber ring on top of it. It must be removed and replaced in its place with a new gasket from the repair kit, after which the assembly is assembled in the reverse order. However, before starting the assembly, be sure that the mixer cavity does not have chips, cracks, shells and other damages, otherwise the replacement of the gasket will be useless, and you will have to replace the mixer.

replacement of the ceramic plate liner

If the gasket of the ceramic plate has leaked out, the mixer starts to hum. Another sign of a faulty gasket is that the water is constantly leaking directly from the mixer, not from under the valve. To replace the gasket, you will need to completely disassemble the axle. There is nothing complicated here, you just have to repeat all the steps from the previous paragraph, except for the last one - at this stage of the work we use a spanner to unscrew the axle from the mixer completely. We disassemble it into two parts - upper and lower, to gain access to the ceramic discs. The gasket is located between the top plate and the disk, usually it is white, but not always. We will have to replace this gasket. After replacement, the assembly is carried out in the reverse order.

change ceramic discs

If the discs are worn out over time, you can try to remove the irregularities, wiping them with the usual simple pencil. Sometimes the problem is different - the ceramic discs themselves are perfectly polished and adjusted to each other, so they do not allow water to pass through. However, if any garbage or grain of sand gets between them, the sealing can be disturbed. Therefore, after disassembly, you need to make sure that the surfaces of the discs are clean. When reassembling it is impossible to tighten the nuts too tightly - this is fraught with damage to threads and gaskets.

Another serious problem is scratches and furrows on the surface of the discs. In this case, a complete replacement of the ceramic disc will be required - they are sold in the form of a repair kit. Having eliminated all the problems, perform the assembly of the mixer and check its functionality.

about the most complicated: boiled cock crane

The reason that the crane can not be removed from the nest can be limestone deposits that tightly adhere the part to the walls of the mixer. How to dismantle the crane axle, if it is said to be "stuck"? Home "masters" often use the method "where a spanner does not help, a big spanner and a hammer will help."

The method, let's say it's straightforward, is questionable, even if you try to unscrew the crane with an axle "werewolf" - turning the key in different directions. With this approach, you can easily break the whole mixer, and this will be the end of repairs. Below we will look at a few really working ways to solve this problem:

Method number 1 - chemical.

Try wetting the thread with Sillit sanitary cleaning liquid. It does quite well with rust and lime. Similarly, the drug WD-40 (double-scale). It can be purchased at any auto parts store.

After using the WD-40, the mixer must be thoroughly cleaned - the preparation is toxic.

If the above chemicals do not solve the problem immediately, try to build around a problematic place some kind of a bath, for example, from plasticine, pour a chemical in it, leave it overnight.

Method number 2 - thermal.

If you can not get chemicals with the chemicals, you can try to warm the screw connection. This method will have to be used at your own peril and risk, and hope that the materials from which the body of the mixer and the box are made have different thermal expansion.

For warm-up, it is best to use a building hair dryer. Particularly radical "masters" manage to use even a blowtorch.

Method number 3 - mechanical.

If the mixer is a Chinese, then with a probability of 99% it is made of low quality, weak and easily deformable material. In this case, you can gently tap the mixer body around the thread with a small hammer. This operation needs to be done repeatedly - there is a small chance that the mixer body is slightly deformed, rust and lime scale will weaken its grip, and the crane will be able to unscrew the axle. However, the Chinese mixer is easier to replace than to repair, so this method, as they say, is an amateur.

In the extreme case, if all the above methods did not work, you can try to drill the axle box. To do this, cut off the protruding part of the part and drill a part of the axle with a drill of the desired diameter, which "became attached" to the thread. Or try to remove it with a milling cutter.

In this case there is a great chance that after such a radical operation the thread in the mixer will have to be cut again.