The combination of wood and metal is considered a classic when decorating interiors of living quarters, and one of the most beautiful and spectacular design solutions. Attractiveness in combination with strength and reliability, a wide variety of colors and stylistic solutions, make metal stairs to the second floor, finished with wood, very popular.

In order to answer the question: how to trim a ladder with a tree, it is necessary to first understand what materials are used for this, what is their difference, and why the tree is best in harmony with the metal. All this, as well as instructions on the covering of the timber frame of the metal ladder you will find in our publication.

Content

Metal staircase with wood trim: the main element of a modern interior

A combined staircase in a modern country house is one of the main finishing figures of the interior. It can be safely called a bright, accentuating detail of the chosen style of decorating a country house.

The staircase, beautifully decorated with details from a natural solid wood, elements of forging, will give any interior a respectable, aristocratic look. A huge variety of configurations, advanced technologies for manufacturing parts, and, of course, the harmony of the combination of natural wood and strong durable metal open the widest scope for the embodiment of the most unusual and bold ideas.

The metal ladders made of wooden elements have good performance characteristics and a long service life, when compared with wooden or plastic counterparts. With regard to the weight of the product, thanks to the use of light alloys in combination with wood, the construction weighs much less than the all-metal or concrete product.

Combined staircases include the main advantages of all-metal and wooden staircases: the elegant metal construction with wood-trimmed steps does not look heavy, but rather, on the contrary - light and fast.

At the same time, it is very reliable and capable of withstanding enormous loads throughout its life. Metal makes the construction durable, wear-resistant and safe, and the wooden elements give it safety and comfort when moving, convenient for descent and lifting, even for children.

As a material for the manufacture of metal ladders it is customary to use the lightest, but at the same time, durable metal grades having increased resistance to corrosion. Depending on the designer's preferences or at the request of the customer, the finish of the metal ladder can be partial (only steps), or complete, including the skin of the whole frame.

What material to choose for metal ladders

The peculiarity of facing the metal staircase is that it can cost you quite cheaply or become the most expensive item of repair costs of the whole house. It all depends on what material will be used for the cladding, and, of course, on personal preferences - whether you want a modest, cozy interstore staircase, or you want to decorate your home with a respectable and graceful design. Depending on the financial possibilities and personal preferences, it is possible to coat the steps with the risers, or only the steps.

When choosing the material that will be used for facing the stairs, it is strongly recommended to give preference to exclusively natural wood. Making a choice in favor of natural wood, you will not lose, as no other material will bring more harmony, freshness and warmth into the interior of your house. The tree is not only beautiful, but also practical material, which has excellent thermal insulation and sound insulation properties, as well as resistance to mechanical damage and a long service life.

One of the main parameters that guide the selection of the material is its humidity. The percentage of humidity has a huge impact on the performance of the product. Excessive moisture greatly reduces the strength of the material, leading to its cracking and deformation. Therefore, when buying material, you need to check the percentage of moisture.

If it does not correspond to the norm, the tree will have to be dried until the moisture level meets the requirements. Otherwise, your new steps in a warm room will begin to deform, creak and wobble, and they will most likely have to be replaced. The percentage of moisture in the freshly cut tree can be from 35 to 100 percent. The finished material should contain no more than 12 percent of moisture.

So, which material is better to trim the ladder?

The most common for facing works are parts made of hardwood: oak, beech, walnut, pear, ash, mahogany, etc.

Oak is attractive, first of all, its strength, durability, beautiful and very rich color range - from a gentle light yellow to dark, reddish-brown tones.

If you chose oak as a facing material, do not forget to take into account one important feature: over time, wood inevitably darkens, acquiring a deeper, rich noble color.

Ash is also very durable and durable material, it is very popular with furniture manufacturers. Wood with a pronounced texture of a beautiful grayish-yellow hue.

Beech is elegance, taste and sophisticated style. Beech wood is very beautiful, has a soft, uniform texture, it is durable and durable. Quite often the beech is used as an imitation "under the mahogany".

A stunning effect is obtained using expensive exotic wood:

teak

wenge

merbau

They have a very beautiful color palette: lemon-yellow, blood-red, brown tones. Growing in warm tropical countries, nature has endowed with an unimaginable variety of textures and color shades. In addition to external appeal, the wood of these species is very durable and durable. Prices for such a wood, of course, are very high, but the result is worth it.

As for the podstupenkov, then you can safely save. Experts recommend to use as a material inexpensive coniferous species: pine, spruce, fir.

Pine is not difficult to handle, it is a soft material with good performance characteristics. Of course, the price of structures lined with this material will be several orders of magnitude lower than that of hardwood analogues.

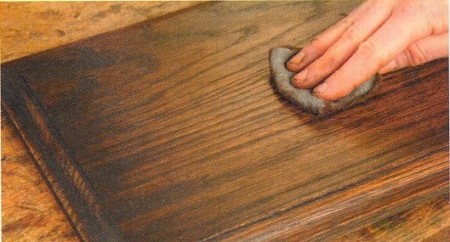

After the veneer is finished, the wooden elements of the staircase can be sunk in almost any color, in addition, wood is recommended to be treated with special compounds that will protect it from cracking, decay and damage by pests and diseases.

If desired, you can contrast the relief and texture of the material, and its natural shade. For this you can use several decorative techniques. For example, a grinder or an electric drill with a metal brush can "comb" the wood.

In this case, soft fibers are removed, and the remaining solid form a beautiful pattern.

After that, using lacquer, stain or other coloring compounds, you can give the stairs the right shade and with a grinder to gently clean the surface. Do this with utmost care, slightly emphasizing the texture of the wood. If everything is done correctly, the paint will remain only in the indentations.

Finishing of stairs with wood: several features of the process

The installation of combined staircases with a metal frame is, first of all, a creative process, and one skill and skills are not enough here, it is necessary to have at least some artistic taste.

To date, the most common and popular way of facing is the fastening to the metal frame of the ladder of wooden steps.

The remaining parts are painted in any suitable color.

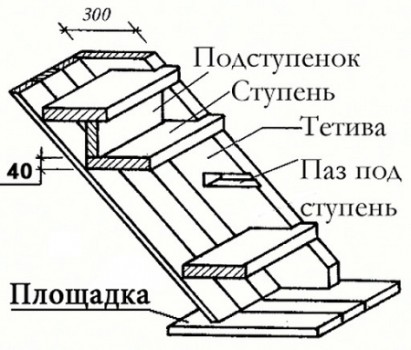

Thanks to this approach, the ready-made interstore ladder harmoniously fits into almost any interior of a private house or a two-storey apartment. If, according to the designer's plan or the wish of the owners of the house, the staircase is to be fully lined with wood, in this case the process is very laborious: it is necessary to perform a whole range of work on the cladding of steps and risers, under the stairs, to imitate the tree of the stair bow and kosoura. After such a "disguise," the interstore ladder will have a complete resemblance to a wooden analog.

Combined ladders are not very whimsical to the conditions of installation and operation. So, if you want to make a combined ladder yourself, and experience in this field you have little or no, then in this case it is strongly recommended for prefabricated staircases that are implemented as ready-made modules. All the details of such structures are made in the factory, meet all GOSTs and standards for metal and wooden staircases.

Prefabricated structures are a set of elements from which stair flights are assembled, which are fastened together in accordance with the attached instruction. The finished stairs are characterized by a high degree of reliability and safety. But it must be recalled that a guarantee of complete safety of the staircase is a periodic inspection in order to identify and eliminate possible malfunctions in a timely manner.

Finishing the metal staircase with your own hands - step by step instruction

Sheathing of the metal ladder is carried out in several stages. At the preparatory stage, choose the appropriate design, prepare the project, and choose the way of skinning the frame. That is, what exactly will we coat - only the steps, or do a complete finish of the staircase marches. Then we determine the type of wood, we purchase the necessary amount of material, prepare all the necessary elements and details of the skin, customize them to the dimensions of the frame.

If the design is simple, then only a hand saw for wood, a large file or sandpaper is required.

- We carefully measure all the elements of the structure.

- We transfer the measurements to the cladding elements.

- Cut out all the details of degrees in size.

- If full lining of the staircase is planned, you need to choose balustrades of the appropriate type.

- In addition to the supporting and protective function, the guardrails of the steps are also very beautiful and spectacular decorative elements.

- An important point: the cross-section and the shape of the handrail should be as comfortable as possible for the palm.

- In addition, it is very important to choose the right interval between balusters. Most often it is made from 15 to 20 centimeters, but if the family has small children, the distance should be reduced to 9-10 centimeters.

- We fix wooden cladding elements. For this purpose, wood screws of the appropriate size are best suited.

- Mark and drill holes in the metal frame.

- We fasten the screws of the details of the wooden paneling to the frame. Screw the self-tapping screw 5-7 mm deep into the wood. Then the traces of the screws can be sealed with a wooden cork or putty.

- We fix with the help of self-tapping balusters. From above on balusters we establish a handrail.

Well, almost everything, there are only finishing works: grinding, toning, painting, etc.

Finally I would like to say that it is not so difficult to transform the appearance of a heavy ladder with the appearance of a metal ladder, as it may seem at first glance. If you decide to do this work on your own - just follow the recommendations, choose the right wood, take the details seriously, and you will succeed.

And for a more detailed study of the issue, we offer the following videos: