For most car enthusiasts, their car is more than just a vehicle. It is a family member who needs constant care and care. And one of the main tasks after buying a car - to ensure its safe storage, that is, the construction or purchase of a garage. Not so long ago to build a garage for your car was a difficult task. Now, in the period of rapid development of building technologies, the garage can be built on its own, and for a relatively short time.

Content

Garage for car on frame technology

Many car owners do not have enough money to build a reliable shelter, and then simplified and cheap designs are used - various awnings, canopies, extensions, etc. These options solve the problem of maintaining the machine only partially. But why clog your site with flimsy temporary annexes, if you can quickly and inexpensively build a frame garage with your own hands, and comfortably keep the car in it all year round? The construction of a garage for wireframe technology does not require the presence of special building knowledge and skills, the garage will not require much material, and it will serve not much less than a brick building. In addition, to build a frame garage you do not need to attract heavy construction equipment.

When constructing a garage, the following important points should be considered:

- The interior space of the frame garage should be protected as much as possible from the environment.

- The design should be as simple as possible so that the owner can repair it at any time.

- To build a garage you do not need to buy expensive materials, the savings here are appropriate.

Advantages of frame technology in the construction of a garage

Wireframe technology has long been known, recognized, and "run-in" in the harsh climate of Canada, Finland, the United States, and more recently - in Russia. Therefore, quite a lot of car owners pay attention to this simple and inexpensive way of building a garage for their iron friend. The design in the vast majority of cases is made of wood, which, however, does not prevent the carcass garages successfully compete with brick and metal analogues.

As mentioned above, one of the main advantages of frame construction is high speed and ease of erection. The nodes of the frame building are assembled simply, with the help of screws and bolts, therefore, construction work can be carried out at any time of the year.

For the work will be quite enough forces of two or three fitters, who will cope with the work in a few weeks. Do not need to rent expensive construction equipment, spend time searching for and drafting contracts. On the construction site, there will not be stacked mountains of construction debris, which will then have to be removed.

We build a skeleton garage: the sequence of works

At first it is necessary to compose at least an unpretentious project of the future frame garage, which will include the order of assembly of the structure and calculations for the number of building materials. Guided by the project, you can pre-calculate the cost of materials and construction in general. Next you need to decide on a place under the garage. The site must be no less than 10x10 meters in size.

frame garage: project

The construction project is a document, according to which all construction work is carried out. The construction project includes the following items:

- Sketch of future construction, and its design model.

- Layout of the foundation.

- Plan the cap.

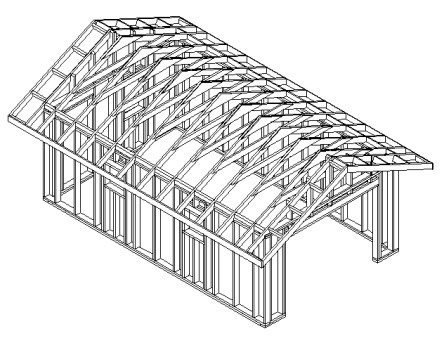

- Scheme of the frame.

- The design of the rafter structure.

- Drawings of all elements of the frame and roof.

- Roofing and drainage system

tips for choosing a place for a skeleton garage

The area under the garage should be chosen so that afterwards nothing would hinder the unhindered exit of the car. If you own a site of your own, and have a free platform of the required sizes - fine. We clean it of debris, foreign objects, destroy all vegetation, level and tamper well.

The layout of the site is strictly according to the plan. After that, along the perimeter of the site, dig a trench, the depth of which is about 40 centimeters. In the trench a wooden formwork is installed on three sides of the site.

The size of the garage depends on the number and dimensions of cars. The ready garage should be spacious enough, and to count the area under kaoy0 one car is not necessary, who knows - in a year you can buy a bigger car. So it is better to build a garage, so to speak, for "growth".

foundation

The foundation is the foundation of any building, ensuring its durability and strength. The choice of the foundation for a skeleton building depends on its design, soil, the proximity of groundwater, and, of course, on the thickness of the purse. Frame structures do not require the presence of a powerful monolithic foundation. The main requirement is to make an even area for the building. For the base, a carefully packed gravel bed, asphalt pavement or concrete slab completely fits. A solid concrete base is a good option for a frame garage. Such a foundation will later serve as a floor, which can be tailored to your liking.

A solid concrete slab, this, the so-called "floating" base, which takes a load on the entire area, preventing deformation. Concrete for the foundation must be not lower than grade 300. After pouring the foundation should stand for three weeks.

socle

After a few weeks, when the concrete will gain strength, you can proceed to the plinth. As a socle the concrete blocks in the size 20х40 centimeters, laid on a cement mortal are quite suitable. Before you begin to mount on the base of the frame, it is laid on the layer of waterproofing.

framework of walls

The frame of the future garage building can be made of different material. But most often give preference to wood or metal. Wood is one of the cheapest materials, but its main disadvantage is high combustibility, so that all the details of the frame must be impregnated with special compounds that prevent the burning of wood.

Metal - the material is more durable and fireproof. The structures of the metal profile are strong, they are connected by welding, which ensures high reliability of the fasteners. Metal frame garage can successfully withstand any whims of the weather, and your car will be reliably protected.

Let's return to the construction of the frame. First, a starting, strapping bar is installed on the plinth. This will be the basis for future garage walls. The beam is attached to the insulated plinth by means of self-expanding anchors in steps of about one and a half meters. The starter bar should be fastened accurately and accurately, otherwise it will be very difficult to fix the errors later.

After that, the remaining elements of the frame are assembled according to the project: install racks, diagonal bunches, all necessary crosspieces and a top banding, finishing bar. All the elements of the wooden frame are fastened together with self-tapping screws 70-90 millimeters.

The front part of the frame garage, through which the car will move, should be equipped with reinforcement elements. On the openings of garage doors reinforced beams are installed. All elements of the frame before the installation is carefully treated with the means of fungi and mold and fire retardants.

wall paneling of frame garage

After the frame is ready, it is lined with OSB plates. After that, the insides are laid from the inside. To do this, you can use mineral wool, polystyrene or expanded polystyrene. Of the external finishing materials, the preference is usually given to the "C" class. In addition, install a windproof layer of pergamina and vertical beams cross-section 25x30 mm. Installation of vertical beams is recommended to be carried out, observing a step of about 30 cm.

Next you need to cover the inner space of the garage. You can do it with inexpensive lining. External lining can be made by siding, imitating a bar, or even a metal profile.

roof

For the installation of the roof frame car necessary boards measuring 100x25 mm of sufficient length. The construction of the roof includes the following steps:

- Installation of the rafter system.

- Installation of vapor barrier layer.

- Installation of thermal insulation.

- Installation of waterproofing.

- Installation of the roof.

No special requirements for the roof are made - it should be easy to maintain and reliable. Russian winters with heavy snowfalls require sufficient strength of the roof structure, which must withstand the weight of snow and the person who cleans the roof. The roof can be made of ordinary slate, metal, metal, ondulin, etc. The main condition is a well-executed installation work. Developers recently prefer metal and corrugated board. These materials, due to the large area of the sheet and a small weight, are stacked very quickly. Metal tile and corrugated board are fastened to the crate by screws for metal using a screwdriver.

One of the main elements of any roof is a drain. For a garage, it can be made from a conventional plastic pipe, cutting it in two in a Bulgarian. Snow in Russia falls very much, so on the roof slopes it is necessary to install snow holders that will prevent the masses of snow and ice from coming down and protect the gutters from damage.

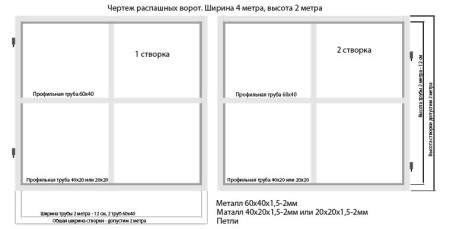

goal

On a frame garage it is possible to establish gates of the most different designs: usual hinged, sliding, sectional, и.т.д. But in order to save, most often prefer a simple swing gate. They are easy to manufacture, they are light and inexpensive. The size of the gate depends on the dimensions of the car. The standard size of swing gates is 2.5 meters.

Gate frames are welded from a metal corner, which is additionally reinforced in places of fastening with metal strips. If you plan to use the top of the frame as a jumper of the door opening, it must be completely covered with metal.

Valves are welded from a metal profile. The finished frame is covered with steel sheets with a thickness of at least 3 mm. The inner bolt for the gate can be made from a conventional tube of suitable diameter and a steel pin. Frame and frame must be protected from corrosion, paying special attention to welding seams. They must be cleaned of slag, cleaned by a Bulgarian. After this, the metal structures are ground and painted.

communications

A full garage must be electrified, equipped with ventilation and heating. It is necessary to bring all communications into the garage, it is necessary to equip it with a natural ventilation system that will clean the room of waste gases and ensure a constant supply of fresh air.

The simplest ventilation consists of small openings in two opposite garage walls, covered with grills.

Very often garages are heated by electric convectors. The type of heating should be necessarily thought out in advance and specified in the project. An electric convector is inexpensive, but this heating will be poured out every month in a tidy sum in the form of electricity bills.

The simplest option is to bring the heating from the house if it is not far from the garage. You can also install a gas convector, but the cost of the project, the heater is quite high, and red tape with the gas services will take a lot of time and money.

Another option is a small pyrolysis boiler with solid fuel and several batteries. The boiler is expensive, but consumes very little fuel, and gives enough heat. In the long run this is a pretty good option.

The wiring in the garage is installed either with channels specially dedicated for this purpose, or in protective corrugation. After installing the RCD, sockets and lighting fixtures.

It is highly desirable to provide natural lighting in the garage by installing several windows.

The facade of the garage can be finished with sheets of corrugated board, for finishing with siding you will need to install an additional crate.

From the inside, the insulation layer is covered with any available finishing material. The ceiling is lined with a lining, under which lay a layer of paper and heat insulator. For the attic floor a board 25 mm thick is used. To enter the attic, a conventional ladder is installed.

We hope that after reading this publication you will get at least a general idea of how to build a frame garage. To complement the theoretical knowledge, we suggest to watch the following video: