The concrete floor is known to us as the coldest coating: at any time of the year the chilling coolness seems to burn the feet, causing severe discomfort and irritation. In addition, the concrete foundation is not suitable for children's games, which means that sooner or later you will think about the need to insulate such a coating. When is it better to insulate the concrete floor in the apartment? Of course, during the approaching repair. With the basic, most effective ways of warming, we will get acquainted in detail in this article.

What is better to insulate the floor of concrete?

If you need to insulate the concrete floor in the apartment, think in advance about materials that can not only visually transform it, but also make it warm and comfortable.

For this, the materials must have the following characteristics:

- moisture resistance;

- low thermal conductivity;

- sufficiently small weight,

- long life.

To such materials for today experts carry:

- expanded clay;

- mineral wool;

- styrofoam;

- expanded polystyrene, including extruded;

- polyurethane foam;

- perlite;

- stone basalt cotton wool.

All these materials can be used depending on the design features and the desired result of the working floor surface.

Ways of concrete floor insulation

Choosing a heater for concrete floors, you should decide on the method of flooring specific coating. There are two methods:

- by lags;

- on a concrete base.

In the first case, the load of heat-insulating materials is not provided, so it is better to use mineral wool, density up to 50kg / m3 or loose materials. When the flooring is applied to the slab, the load increases, and it can be supported by mineral or extruded polystyrene boards.

Installation of floor covering on the basis of logs

Flooring flooring in this way is done at the beginning of the construction of the house during the stage of laying the floor of concrete. Provided that the floor - clean, you can use floorboards, moisture resistant plywood or chipboard, which are attached to the lags.

It should be borne in mind that this method leads to a reduction in the height of the ceilings by 7-10 cm. Therefore, if your apartment has low ceilings, once again think about the advisability of such an approach.

Quality styling involves the following:

- the cleaned concrete base is covered with a layer of waterproofing material, for example, a thick polyethylene film;

- with a hydraulic level, lags are installed on the floor surface at a distance of 50-60 cm from each other;

- the spaces between the lags are filled with heat-insulating material;

- taking into account the deviation from the wall surface in 15 mm, boards, plywood or chipboard are installed;

- flooring is made.

Installation of "floating floors"

The method based on the use of strong and durable extruded polystyrene foam for insulation of the concrete floor is very popular and common. The technology includes the creation of several layers, the last of which is a cement-sand screed, which is not attached to the walls or to the base. This layer is like "floating". Due to this feature, the floor is provided with an excellent soundproofing quality.

When creating a heated floor, slabs made of extruded polystyrene foam will become a valuable material. In this case, they act as a reflective screen.

The technology of insulation of concrete floor assumes the following order:

- flooring;

- substrate;

- sand-cement screed;

- concrete floor base;

- heating elements;

- extruded polystyrene foam.

In addition to these methods of insulation of the concrete floor, there are simpler and no less effective designs, as well as materials that have a high level of thermal insulation.

They include:

- thick waterproof plywood;

- wood chipboards;

- rolled isolon;

- cork cover for technical purposes;

- carpet or insulated linoleum.

The flooring of these materials is preceded by careful alignment of the concrete surface, cleaning it from dirt and dust. Then you can go directly to the insulation.

Warming of concrete floor on the basis of wood-shaving plates

The most elementary and inexpensive way of warming a concrete surface is the use of chipboard.

The design includes:

- covering the floor surface;

- particleboard;

- waterproofing materials.

The technology of this method assumes the following sequence of actions:

- a polyethylene film is laid on the concrete base, providing the necessary level of waterproofing;

- a small deformation layer is left between the wall and the slabs, into which a number of plates are laid. This layer is designed to protect the plates from deformation when the humidity or the temperature in the room change;

- the fastening of the subsequent layer is made taking into account the indentation from the wall, while excluding the formation of cruciform seams. In this way, the floor covering is mounted on the entire floor surface. Fixing of plates is carried out with the help of dowels;

- at the end of fixing the plates, the docking sites are sealed with a building mesh, processed with a mixture of putty and oil paint of the desired shade. Alternatively, you can use wood sawdust or crushed limestone mixed with varnish for a parquet board. The best ratio is 1: 1. This mixture is excellent for sealing cracks and seams;

- right after the laying of wood-chip boards, plinths are fixed;

- the prepared surface is suitable for mounting the finish coat. It can be carpet or linoleum.

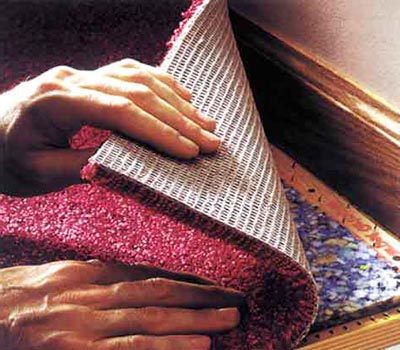

It should be noted that carpeting and linoleum are considered good insulating material for an apartment or a house. These coatings are glued to the bustilate to a concrete base with a substrate of polyurethane foam, or they are firmly pressed against the floor by a skirting board. In the case of joints, the coating is overlapped (5 cm) and cut. This method will create a perfectly smooth and almost unnoticeable seam.

At the same time, let us recall the main disadvantages of linoleum:

- fragility;

- due to the low density and uneven base, the linoleum pushes;

- made of synthetic materials.

Technical cork as a concrete floor insulation.

Thermal insulation of the concrete floor is successfully accomplished by using a technical plug 3-10 mm thick. Being very thin, this material has the property of keeping heat for a long time.

Excellent thermal insulation and performance characteristics, environmental friendliness and safety of use, the possibility of using in rooms with low ceilings combined with an acceptable price determine the success of the technical plug for insulation of the concrete floor.

Insulation of the floor with insulating glass

Being a popular and inexpensive insulating material, isolon serves for quick, and most importantly, high-quality insulation of the concrete floor for more expensive coatings - laminate or parquet. It is rolled on the surface and fixed with an adhesive tape.

On how to properly insulate the floor of concrete, you can learn more about the video on youtube.