After the frame is fully built, it must be sanded. Sanding the log house gives the structure a more aesthetic appearance, will make it stronger and more durable. How to polish the frame with your own hands, and what tools to use at the same time - we read below.

Content

Advantages of a wooden frame

Before proceeding directly to the technology of grinding the log cabins, let us briefly familiarize ourselves with the advantages of this type of housing:

• Wood - a natural humidity regulator in the room - thanks to the natural property to absorb moisture, the walls of the wooden frame absorb its excess, and if necessary - give.

• The ability of the wood to "breathe" ensures a constant natural ventilation inside the room without letting the heat out. This fact has a very positive effect on the comfort and comfort of people living in the house.

• The tree conducts heat very poorly, in itself being an excellent heat insulator - the wooden house is warmed up quickly and the heat remains for a long time inside.

• The wooden frame well resists deformation, the walls of the frame are light and do not require a massive expensive base.

• Among other things, wood is an excellent soundproofing device, it has exceptional resistance to negative temperatures. The construction of a wooden frame will cost less than a brick or solid house.

Why do I need to grind a wooden house?

Most developers do not realize the importance of this operation, although professional builders insist on its necessity. Grinding the log-house with your own hands is a time-consuming and difficult task. In the process of grinding, the defects removed from the surface of the logs are removed from the previous log processing, the appearance of the wood is significantly improved, its structure is emphasized. In addition, grinding can reduce the consumption of paintwork materials.

If the surface of the log is polished well, it is less prone to fungus and mold damage, which causes decay and damage to the wood. The rough surface represents an excellent medium for reproduction and growth of harmful microflora. Despite the laboriousness of grinding work, they are nevertheless recommended to be done on their own, since, firstly, there is nothing complicated here, and secondly, no one is better than the owner of this job.

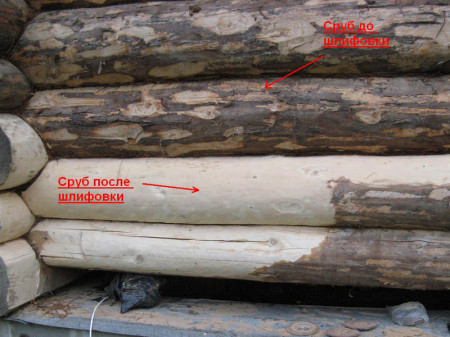

A fresh, only constructed wooden frame has a pleasant warm golden color. After the logs dry up, the bast fiber begins to peel off from them.

In the process of grinding, the detachments are removed, as a result of which the walls of the log house look more attractive and neat.

If the logs for the log were treated with a plane, there will always be marks on the surface of the tool. The log is slightly faceted, because with the help of the plane you can remove up to 3 cm of wood. With the help of grinding you can completely get rid of the traces of the plane and give the log its natural round shape.

When the log was cleaned of the bark recently, its surface remains smooth and even for a while. As it dries, the log becomes rough, pile rises, which is also removed by grinding.

When is it better to begin grinding the log?

Before starting the grinding process, the frame must be fully assembled, including the roof.

This condition must be observed, so that the grinding of the log-house with its own hands is not in vain. You can not grind the newly assembled log cabin, because the logs are still quite raw (the grinding wheel will be very clogged). If the frame was assembled in the warm season, you can start grinding not earlier than a month after its complete assembly and installation.

Sometimes during the assembly of the building, the logs can darken or turn blue.

In this case, they are preliminarily treated with a special bleaching agent-antiseptic. Only after the surface dries well, you can begin grinding. Do not try to immediately polish a large area, it is better to conditionally break it into small areas. Each polished section should be impregnated with antiseptic composition as soon as possible.

If the polished frame is not treated with antiseptic paint or varnish for a week, the material will begin to darken again. In this situation, the processing process will need to be completely repeated. In order for the frame to be of the same shade, painting or other processing of its surface should be made no later than four days after the end of the grinding work.

Tools for grinding the frame

You need the following tools to work:

• Bulgarian or angular grinder.

• Parquet grinding machine of disk or tape type.

• A set of tips for grinding.

• A vacuum cleaner.

• Respirator.

• Points.

If you have the time and desire to polish the frame yourself, first you need to choose the right tool for the job. To work was without unnecessary difficulties, do not choose heavy tools. Also it is worth paying attention to the power - a weak power tool will quickly heat up - it takes a lot longer to work.

If the frame is made of a bar, a great solution will be a belt sanding machine, with which you can very accurately handle a flat surface.

That in the course of work the wood dust is not released into the air, such a tool is equipped with a special bag that collects saws and sawdust, so after work the room remains relatively clean.

For grinding walls, collected from logs, the tape machine can not be used.

In this case, it is best to use a small grinder fitted with special grinding attachments. You can use special discs on which glued paper is glued. In hard-to-reach places it is advisable to use a chisel.

When choosing a grinder for grinding a log, it is recommended to pay attention to its weight, if the tool is too heavy, it will be difficult and uncomfortable to work. The recommended optimum power of the tool is from 600 to 900 W. At purchase it is recommended to give preference to the checked up manufacturers and necessarily to demand a guarantee on the goods.

It will not be superfluous to once again remind you that you can start grinding only after the tree has dried. If you neglect this and start working immediately after assembling the house, then the wet wood will not be polished.

Before work it is necessary to be reserved by necessary quantity of nozzles having different granularity. This is necessary for the reason that certain parts of the walls will require individual grinding. When the primary grinding of the walls is most preferable to use coarse-grained packing (40), for carrying out the latter, finishing grinding will suffice to use the nozzle 80-100.

Technology of grinding the frame

The grinding process can be divided into the following stages:

• Roughly peeling the surface of logs.

• Basic processing: removing unevenness and smoothing the surface.

• Finishing.

• Treatments before applying paint or varnish.

In the process of work, it is often necessary to change tool attachments, since resin and wood dust quickly "eat" them. To clean the nozzle from accumulated particles of wood and resin, it must be treated with white spirit, then clean the surface with a steel brush for metal. A cleaned nozzle will, of course, work worse than a new one and will quickly become completely useless.

The speed of the grinding process depends on:

• The availability of skills in working with the tool.

• The type of wood from which the frame was built.

• The area to be processed.

• Presence of complex elements in the architecture of the building.

• The power of the tool.

• The percentage of resin in the wood.

The average processing speed of the running meter of a thirty-centimeter bar is approximately two minutes.

Do not neglect the safety requirements, because when working in the air, wood dust, tar and small sawdust are released, which fall on the mucous membranes of the nose, mouth and eyes. To protect them, you must use a respirator, a face mask and protective clothing.

As mentioned above, the grinding process can be started only after the wood has dried out and the building gives a minimal shrinkage. With the help of the grinder, large areas of walls are easily accessible. In hard-to-reach places it is necessary to work with a hand tool.

In most cases, for the complete grinding of the log from inside and outside, it is sufficient to have an eccentric grinder, a medium-sized grinder and a 2 centimeter chisel.

Several recommendations for grinding work:

If the area of the walls is large, it is better to divide them into small sections, and to do the work in parts, do not try to polish everything at once. After the grinding of one section is finished, it must be combated with the same antiseptic composition.

If one day, polish a large area and not process it, and on the second day immediately begin to polish the next square, the first in a few days will begin to darken. It is recommended to open the ground surface no later than 24 hours after the end of work, otherwise it will begin to darken. Professional builders recommend applying paint or varnish a maximum of 36-48 hours after finishing the grinding work.

The process of grinding the frame must be done in several stages. At the first stage, the surface is ground with coarse abrasive elements. With their help unevenness is eliminated, roughness and peeling are removed, the pile is not damaged.

In order to remove the raised pile, spend the next stage of grinding, working fine-grained nozzles.

If there is no experience in grinding work, it is not recommended to use a powerful grinder. The tool has very high speed and the beginner will be very difficult with his help to smoothly and accurately polish the surface. If you press the tool too hard, furrows and grooves will appear on the surface, which greatly damage the appearance of the frame. Therefore, it is better for beginners to use the Bulgarian only for processing grooves and end walls.

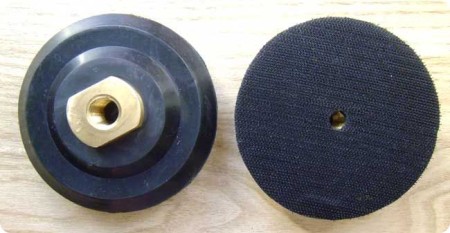

To handle the grooves of the frame, you need to purchase special flat tips for the angle grinder. On sale there are plastic and rubber nozzles. For this kind of work, plastic ones are best suited, since rubber nozzles are impractical - they very quickly fail and require frequent replacement.

The nozzle should be slightly smaller than the replaceable grinding disc. If the nozzle when working gets into the groove, the tool jams, and it can break out of the hands, which is fraught with injuries.

To qualitatively polish logs, you need a small Bulgarian with a disk equipped with a "Velcro", on which you can attach circles of sandpaper of different grain sizes. Working with such a tool requires some experience and accuracy.

If the frame was assembled in the warm season, and after the assembly is dry and hot weather, grinding can begin in 10-14 days. In wet weather, the log can not be ground.

At the beginning of the work, abrasive grinding is done, using a grinder and a grinder.

After that, the processing of the areas is done with the help of nozzles made of sandpaper or abrasive elements of less granularity. The process lasts until the surface of the log house is completely smooth and smooth. The last stage - finishing polishing is recommended to be done manually, especially in hard-to-reach places and at the joints of logs. One of the main conditions for the correct execution of work is to quickly process the polished surface with antiseptics and paint and varnish materials that will prevent the infection of the wood with fungus and mold.

After the end of grinding work

Correctly and timely made external processing of the wooden house prolongs the period of its operation several times. The set of works includes polishing and impregnating the surface with subsequent application of paint and varnish materials.

The modern market offers a wide range of compositions of domestic and foreign manufacturers, intended for processing logs after grinding. Not all of these funds are suitable for application to the interior surface of living quarters, so it is recommended that you carefully read the instructions for use when buying.

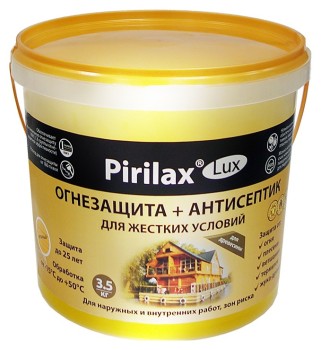

Means for compulsory processing of finished log:

• Antiseptics that prevent the appearance and development of fungus and mold.

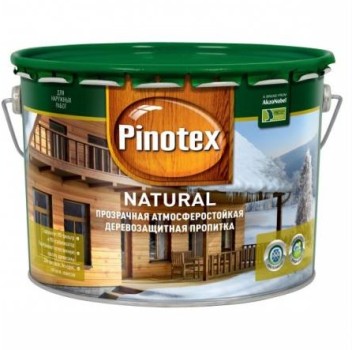

• Letting compounds - give the walls a more attractive appearance.

• Fire retardants - solutions that protect wood from fire.

The main goal with which the frame is polished and painted is to protect it as much as possible from the effects of atmospheric factors, pests and fires. In addition, with the help of special compounds, you can emphasize the texture of the tree and make it tinted. You can use ordinary paint on wood, only in this case under the layer of paint the texture of the tree will not be visible.

First of all, an antiseptic is applied, after that, the surface bleaching is performed, after which fireproof impregnations are used.

You can paint the frame with a brush or with the help of an atomizer. If the log house is log, it will be more convenient to use a spray gun.

Before you apply paintwork materials, you need to again check the quality of grinding and check whether the caulk is sticking out of the joints, which could be removed during the grinding process. Fragments of caulk from the joints must be removed and treated with a sealant, which will prevent the penetration of moisture between the joints.

Particular attention when applying paintwork should be given to the processing of the ends. To do this, use acrylic solutions or water glass. Please note that liquid glass is a toxic material and is not suitable for indoor treatment. These solutions need to be applied to the ends in several layers. Before applying the second layer, the first one must completely dry.

Walls start to be processed immediately after finishing grinding at a positive air temperature. The first layer performs a scaling function. Apply paint and varnish compositions with a brush or spray, for log cabins you can use a roller.

The main condition for high-quality processing of log walls is the use of only high-quality products from proven manufacturers. On materials and tools, you can not save, because the tree is a fairly vulnerable material that requires quality care and processing.