The majority of the population in the household actively uses natural gas, it is used for heating the house, heating water, cooking food. Gas is a flammable product that is capable of creating an explosion hazard during storage, so the installation of gas appliances is carried out according to strictly defined rules, by qualified specialists. In order to install the gas equipment, it will also be necessary to obtain an appropriate permit from the gas office.

Content

Gas appliances, basic connection rules

The connection of gas appliances must be carried out exactly in accordance with the project. According to the rules, the room intended for installation of gas equipment should be:

- is equipped with supply and exhaust ventilation,

- have a source of natural light, i.e. window.

To install in private homes and apartments only manufactured in the factory heating devices, plates and columns that have factory passports are allowed. If institutions require the use of non-standard equipment, then it must be manufactured in accordance with a special project.

Installation of gas meter

Installation of measuring gas equipment is a very important moment, the gas meter allows you to monitor fuel costs, and analyze them and plan for more rational use.

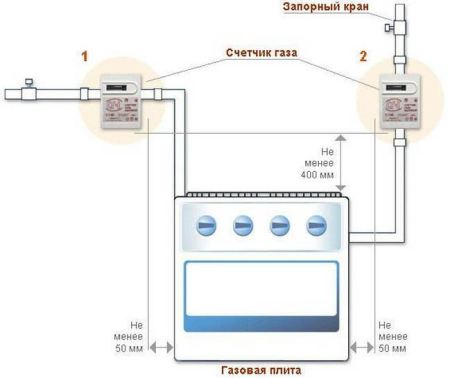

The meter is installed at a height of 160 to 180 cm above the floor level, in addition, the distance to the nearest open fire source should not be less than 80 cm. The height of the shut-off valve installation in this case should be equal to one and a half meters.

If the central apartment has central heating and hot water supply, the meter installation is not mandatory. The height of the laying of the supply gas pipeline in this case should be equal to 170 cm, the installation of the crane is performed at a distance of 20 cm from the plate, from the side.

Rules for installing gas appliances - how to install a gas stove

A sufficient condition for installing a gas cooker is a window with a window (transom) to which there is free access. To the plate itself, an approach must be provided on both sides. The plate is not allowed to be placed in front of the window - the movement of air can lead to a flame displacement. Do not push the cooker to the wall for a distance of less than 5 cm.

If the gas stove is installed near a non-plastered wooden wall, it will be necessary to cover the area of the wall near the slab with a sheet of roofing iron or an asbestos plate. The width of the passage in front of the plate must be at least 1 m. It must necessarily be leveled in a horizontal position, and all its legs should be placed on the floor.

The distance from the installed gas stove to the rigid gas pipeline should not be more than 4 m. When connecting the gas valve and the hose, a dielectric insert must be installed.

As modern plates are equipped with electric ignition and oven lighting, they will need to be connected to the mains, the outlet installed in the kitchen must be grounded.

For flexible gas supply to the plates you can use three types of hoses:

- rubber-cloth,

- rubber with a metal braid on which there must be a yellow marking (for water marking blue and red),

- bellows metal hose, the most expensive, but also the most reliable.

The internal diameter of the hose should be at least 10 mm, too thin can not provide a normal gas supply for the oven and all the burners.

The rules for installing a gas cooker require that it be checked before installation. There are certain rules on which a specialist conducts a test. This mandatory procedure helps to detect the following problems:

- a loose use of burners to the nests,

- incorrect fixing of the handle of the cock,

- seizure of handles when turning,

- damage to the nozzle of a mechanical nature and the like.

In addition, the plate must pass a leak test. It can be carried out by applying a thick soap foam on the joint area. When the gas supply is switched on, bubbles on the surface of the foam should not appear.

Installation of the gas cooker is made according to the scheme attached to the document for this product. Installation of gas equipment is carried out according to the same rules, regardless of whether it is carried out in a private house, in a city apartment or in a cottage.

More details on the rules for installing a gas cooker look at the video:

Installation of flow-through gas water heaters

Gas water heaters, or columns, can be installed only on concrete or brick walls finished with non-combustible materials. If the walls in the house are wooden, they must necessarily be plastered, in addition, the wall near the gas appliance should be covered with an asbestos or metal sheet, the distance from the column to the wall should be at least 3 cm.

If ceramic tiles serve as the finishing of the wooden wall, then the iron or asbestos upholstery is not required, but the distance from the wall to the heating device should be increased to 5 cm.

On non-plastered wooden surfaces, water heating columns must not be installed.

Columns are installed at such a height that from the burner to the floor was not less than 100-120 cm. If the water heater is installed above the bath, it is better to do this from the side of the bath outlet.

Installation of gas heaters is performed on special metal strips attached to the wall. To ensure complete removal of smoke equip chimneys from the gas burner. It is strictly forbidden to include gas columns without the presence of a smoke extraction system in a separate chimney - usually the cubic capacity of the bathrooms is small, the ingress of combustion products into the air can cause severe poisoning.

Since the amount of air necessary for combustion of the gas flows to the burner directly from the bathroom room, it is necessary to leave a specially provided clearance between the bathroom door and the floor for airflow into the room.

On the features of connecting gas columns look at the video:

Requirements for the installation of a gas boiler

Gas boilers are the most common option for heating a private house today. But the installation and operation of such equipment should be treated with special attention, if improperly installed and operated, it can cause a fire or explosion. The installation of gas boilers should be carried out in accordance with applicable state standards. Guided by the regulations should be on the design process of the building and its construction, if the installation is made in the old house, then the choice of the room should be taken very seriously.

The requirements for the boiler room are as follows:

- the room must be separate, the installation of the boiler in the living room is prohibited,

- ceilings should have a height of at least 2.2 m,

- to install a single boiler will require a minimum of 4 square meters. m area,

- the walls of the utility room must be covered with non-flammable, better simply plastered,

- the flooring should be made of non-flammable material,

- the width of the doorway should be 0, 8 m,

- the area of the windows facing the street should be 0.3 sq.m. for every 10 cubic meters of room volume.

In the room assigned to the boiler room you need to sum up:

- gas, equip the shut-off unit for the installed boiler,

- sewerage, for the installation of emergency drains from the heating system and boiler,

- electricity, 220 V, with automatic network protection and grounding,

- water supply, with the possibility of connecting hot water and heating systems.

Each parameter of the installed communication structures must comply with the normatively established one.

An obligatory condition for safe operation of the boiler house is the creation of an effective ventilation system. Exit to the ventilation system must be on the ceiling of the boiler room, and the ventilation itself must have a message with the general ventilation system of the house.

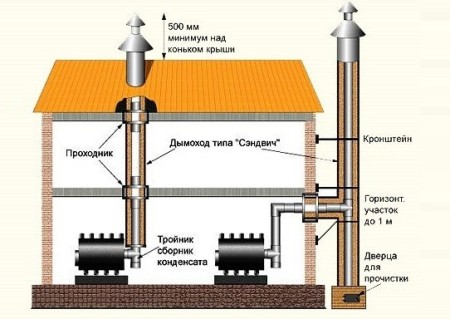

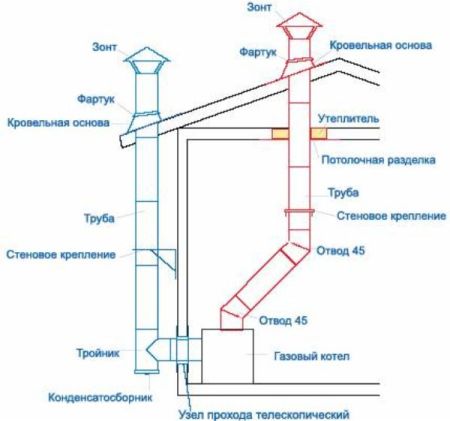

It will be necessary to equip the two chimney channels, for the installation of the chimney and its cleaning. For air supply can be used installed in the door ventilation grill, while for each 1 kW power boiler will need at least 8 square meters. cm of the grid area when supplying air from the street or 30 square meters. cm when supplying air from inside the building.

Certain requirements are also imposed on the chimney:

- it should be airtight and not allow the possibility of smoke penetration into the room,

- the size of the exhaust opening should be equal to the area of the boiler flue,

- the height of the upper cut must be above the ridge of the roof, this will prevent the possibility of air sucking through the chimney.

Installation of the gas boiler can be carried out away from sources of open flame. The boiler must be accessible to the approach from either side. The rules for installing a gas boiler allow you to refuse the arrangement of natural draft, for boilers with forced removal of smoke, it will be sufficient to install a chimney above the roof and install a fan in the chimney. A rational solution is the arrangement of a coaxial chimney. He represents two pipes, one of which is enclosed in the other. Air from the outside is fed into the combustion chamber along the outer annular channel. Since inside the structure there is a pipe with hot smoky gases, the supplied fresh air will have time to warm up well, this significantly increases the efficiency of the boiler operation.

If a fan is included in the kit of the floor gas boiler, then during operation it creates considerable noise. Therefore, experts recommend installing floor gas heating appliances in basements or in the basement of the house. Select the place of envy from the type of unit (floor or wall).

On the rules of installing gas boilers and equipping chimneys in a wooden house, look at the video:

It is necessary to warn owners of houses - the installation of such equipment as a gas heating boiler should be performed by professionals who have the appropriate license for the production of works of this complexity. Often, installation services are offered to companies engaged in the implementation of gas appliances, there is no point in abandoning the help of specialists.

Features of the arrangement of chimneys

Gas appliances used for domestic purposes must be connected to separate chimneys. In cases where the use of a separate chimney is not possible for some reason, the connection is made to a common chimney, but it involves the arrangement of a system with different levels of combustion products.

Usually chimneys are made inside the walls. The area of the pipes used should be at least 150 square meters. cm, for example - 13 x 13 cm. On the whole length of the chimney there should be no horizontal parts.

In those areas where chimneys are located near the wooden elements of the structure, they arrange cuttings made of non-combustible materials.

The top of the chimney is protected by an umbrella made of metal. It will exclude the possibility of penetration of atmospheric precipitation of various kinds inside the chimney. Umbrella is often made removable. This makes it easier to pipe clean.

The connection of gas appliances and chimneys is made of galvanized or roofing steel. Diameters of connecting pipes and nozzles of devices should correspond. For the production of bends use sheet steel.

The vertical part of the connection (from the bottom of the nozzle to the horizontal part of the pipe axis) must be at least 0.5 m.

The length of horizontal joints should not exceed:

- for buildings under construction - 3 m,

- for those built earlier - 6 m.

Turns are allowed in the connecting structure, but not more than 3. The radius of the turning curves should not be less than the diameter of the pipe.

The connecting pipe links must be as tight and free as possible during installation. The end of the pipe-connection is inserted into the smoke channel, that is, into the masonry, at least 10 cm. Here it is necessary to use a restriction device (corrugation or washer), which will prevent the projection of the end of the connection beyond the channel wall.

Safety standards are strictly prohibited from laying pipe connections through living quarters. Pipes-connections located in unheated rooms are insulated.

On the construction of a coaxial chimney on video: