Today the centuries-old technique of hot enamel has turned into the newest technology - fusing. Simple and magical glass material, sintered in a special furnace, becomes a uniform structure, leaving the contours of the pattern airy and transparent.

Content

Meet the glass fusing

The recently introduced innovative glass sintering technology in the oven aroused keen interest and enthusiastic perception.

The existing technology of making stained-glass windows using a metal base was replaced by glass fusing. Now the technology achieves a stunning effect of stained glass, harmoniously blending into the interior.

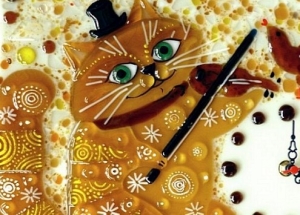

You can start acquaintance with fusing with these works.

Fusing in the interior of the apartment

Fusing stained glass and decorative elements are literally created in order to revitalize any interior. Even the most gloomy and boring room will shine with new colors, if you decorate with such glass interior doors, windows on loggias and balconies.

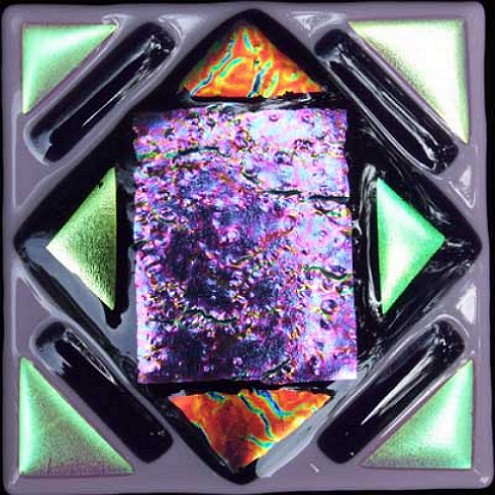

Glazing with glass fusing products is not the only winning variant of the decor. The glass sintering technique can be used for the manufacture and decoration of individual elements:

• inserts in the ceiling elements and the door

• decoration of fixtures

• inserts in stained glass.

Such inserts will serve as an elite and rich complement to the interior of the apartment.

On the walls of the bathroom or kitchen, you can place glass panels, replacing and refreshing podnadoevshy decor. The interior of the room under the influence and "pressure" of the shining colored glass will acquire a presentable and stylish appearance. By the way, having mastered the technique of fusing, you can make a lamp for your lamp or an original vase for your living room and cabinet.

Principles of the organization of fusing technology

The glass sintering technique assumes for the basis of the stained glass a kind of canvas - a glass sheet, on which the figure is embodied. Thanks to the use of pieces and crumbs of glass, the image on the glass sheet can be created volumetric and structural, leaving individual areas flat. Therefore, fusion is provided with a wealth of choice and creation of a drawing, starting from an easy watercolor and ending with an abstract, rich drawing.

All the charm of the stained glass is enclosed in a glass base, letting through the light. The glass base helps to obtain the volume, depth and illusion of perspective, which are absent when working with a metal base. The purity and brightness of colors, as well as the delicacy of graphics, transforms enamel products into glass paintings.

In comparison with the traditional techniques of making stained-glass windows, the fusing of stained-glass windows is already in a new quality:

• the stained glass becomes multilayered

• it becomes possible to create a relief structure

• absence of seams between sintered elements and uniformity of stained glass.

It is not difficult to guess that the main tool of labor for fusing is a special furnace in which glass is sintered at a temperature of 800 degrees.

Manufacturing of decor elements by own hands.

Furnaces for fusing

Furnace for professional roasting

Furnaces for professional fusing are manufactured by manufacturers of sheet metal up to 1.5 mm thick. For internal furnaces of furnaces use refractory materials from the natural materials possessing such quality. These are lightweight refractory panels.

The design of fusing ovens consists of a volumetric chamber for firing. To facilitate lifting the roof of the furnace, gas shock absorbers are used. As the heating element, an electric thermocouple TXA made of fechral is used. Alloy from fechral is used in the creation of powerful potent furnaces and energy-saving heat sources. Therefore, professional furnaces perform firing of glass at an operating temperature of 800 to 950 degrees.

The firing process in professional furnaces is carried out with the help of microprocessor technology, and the power unit control is automated. Let's say that the oven for professional roasting costs a lot, so it is used exclusively for small-scale production of glass products.

Furnace for fusing at home

How do you think, with the use of what technology can you make the burning of glass? You'll never guess! Using a microwave oven. An excellent device for baking not only pies, but also self-made jewelry made of glass and decor elements. The firing technology is simple in this case: a Hot Pot (Microwave Kiln) fusing furnace is installed inside the microwave oven.

The furnace has a miniature geometric dimensions and is made of environmentally friendly material. The inside of the furnace is black and has a special coating of heat-resistant material. It is thanks to the properties of this coating that it is possible to achieve high temperatures when heated. Glass and glass products melted in the oven in a few minutes.

There are two types of oven for domestic use:

• Standard Hot Pot with an internal diameter of 8 cm.

• Maxi Hot Pot with an internal diameter of 12 cm.

"Magic pot" is supplied by the manufacturer with a set for roasting: glass base, colored glass, glass cutter and even thermo-gloves. Well, take it and start creating masterpieces! How to make a glass fusing with your own hands?

Fusing with own hands

Preparation of glass

Prepare a sketch of the fusing pattern. Choose simple geometric shapes that can easily be brought to the original pattern with a glass cutter and glass turning. We prepare small pieces of glass, gently carving out the blanks of the drawing using a glass cutter and wire cutters.

The procedure for the preparation of glass or "molding" can be done in several ways, giving the glass a peculiar shape of the bowl or using the already prepared molding molding.

To create and draw individual elements of the pattern, you can use a frit (a glass crumb). Work with glass chips must be carefully and carefully, because the miniature fritt almost has no weight. But what a rich and colorful picture can be created using a glass crumb.

Preparation of paper

Prepare a special fusing paper and a glass blank for the drawing. It is recommended that the paper is larger than the glass by 5-10 mm. The prepared piece of paper is laid out.

Sintering process

We transfer to the bottom of the stove the paper with a patterned glass and close the microwave. For the firing process and sintering of glass, preference is given to the microwave mode.

In this case, the maximum power and the processing time are selected - 3 minutes. Suitable glass sintering time is selected depending on the area and thickness of the glass pattern. The process of glass sintering must be controlled.

The fusing oven in the home is operated by an individual program, which is intended for a single glass product.

After the end of the sintering process, do not rush to take out the glass "pizza". Let it absorb all the joy, strength and beauty of man-made art!