What self-respecting car enthusiast will want to leave his car in the open? Yes, if the car is still brand new and expensive? The car is destructively affected by atmospheric precipitation, besides it is necessary to take into account the high probability of hijacking a car left unattended. If there is a possibility to park a car in a guarded parking lot - this, of course, is good, but your own garage is an ideal option. Below we will tell you about the manufacturing of a metal garage by one's own hands, as one of the simplest and inexpensive options of protection for a car.

Content

What a good metal garage

Garage can be built of wood, block, brick, pour walls of concrete, make a frame building - lots of options. But the wooden structures for cars are too good to burn, and if we take into account the fact that there may be a store of fuel and lubricants in the garage, it is better to refuse from the wooden garage. Wooden structures will need to be carefully treated with special impregnations, which prevent inflammation and damage to wood by pests. If you are willing to spend time and money on studying all the subtleties of erecting and protecting wooden buildings, you can try. To build a good building of brick, block or concrete is also quite difficult and expensive, besides it will be considered a capital structure - it will require the registration of many permits and documents, and this time and money.

Metal garage, whose price is significantly lower than the capital building - economical, simple and fairly quick solution of the problem. It does not require an expensive powerful foundation, you do not need to make out a lot of documents, and invest in construction of large funds.

The main advantages of metal garages include: high protection from ignition, a relatively low cost of materials and a good degree of protection against thieves.

As we have already said, a metal garage is not considered a capital structure, it is a good opportunity to avoid paper red tape and immediately start construction work.

In fact, this is a very simple design, which, if desired, can make every car owner, and very quickly. It will only be necessary to pour or collect the floor, make a simple supporting base, frame, and trim it with sheets of metal. But even though the metal garage is simple in design and construction, many details may have to be done on their own and strictly adhere to the technology.

The metal garage can be skeleton, demountable and welded. A metal garage is collapsible - a more solid, stable and reliable construction, but welded buildings are built much faster and easier, and if necessary they can be quickly disassembled, transported to another location and quickly assembled. To determine the choice of the design of a metal garage, it is necessary to imagine how much the garage should have, where it will stand, and what exactly the building will be designed for.

Recommendations for choosing a place for a garage

This is a very important moment. The building should be a short distance from the apartment building and in no case should it be adjacent to the windows. Garage can not be built in the lowlands and areas flooded with rain or meltwater, as well as closely-lying groundwater.

A prerequisite is the provision of free and convenient entry and exit to the premises.

Planning the area of the future garage, you need to consider not only the dimensions of the car, but also the availability of spare space for spare parts, spare tires, tools and other necessary things. In addition, it is quite possible, in the future you will want to buy more cars, this also needs to be taken into account at the planning stage. The most common dimensions of garages are 3.6x7 meters.

Construction Materials

To build a metal garage with their own hands, the following materials will be needed:

- Round or shaped metal tube for the production of load-bearing elements.

- Sheet metal.

- Profiles.

- Parts for fasteners.

- Materials for the inner skin.

- Concrete solution or components for its manufacture.

It is best to use a corrosion-protected, galvanized sheet metal. One of the best materials for the plating of metal garage is the corrugated board. It is reliable enough and durable. True, the cost of the corrugated board is slightly higher than the usual sheet metal of the same thickness. The metal sheet, covered with a layer of primer, will cost less, but it will also serve much less.

Future Garage Project

Despite the fact that the metal garage can not be called a complex building, it is still possible to make the project. It is not necessary to translate the piles of paper onto it, trying to display each node and detail. It will be enough to draw on paper a drawing of a metal garage as a whole, indicating its exact dimensions, as well as displaying the main details - the gate and the roof. This unpretentious project will not only significantly speed up the work, but also help correctly calculate the required amount of building materials.

In the process of developing the project, one should also try to take into account the tasks that the metal garage will perform: will there be repair work in it, is there a planned inspection pit, or will the building serve only as a storage place for the car.

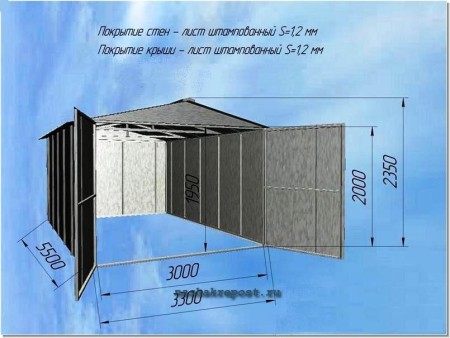

The design should also take into account the dimensions of the car, in the calculation of the purchase of a more bulky vehicle in the future. The size of the construction site is determined depending on its characteristics and the total area on which the construction is planned, and on what tasks the developer is pursuing. For example, if the garage is planned only for parking and storage of a car, it will be enough to build a garage with dimensions of 3x5.5 meters, unless, of course, you plan to keep something like a "Hummer" in it. Dimensions of the building vary in the larger side, in the case when it is planned to keep equipment and tools in the garage, in such a way that there is always a free passage of at least one meter along the perimeter of the standing car in the garage.

Layout of the construction site

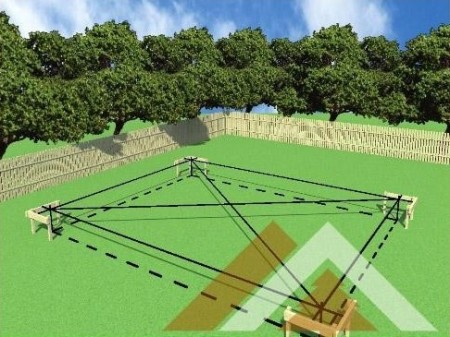

At this stage of the work, it is necessary to transfer the drawing of the future garage, so to speak, from the paper to the ground. To do this, it will take ten to one and a half pegs about 40 centimeters in length. You can use scraps of steel wire or reinforcement with a diameter of 10-12 mm. You will also need a small sledgehammer or a hammer, a roulette measuring at least 5 meters in length and a nylon cord or a construction line of bright color - about 40 meters. If the inspection hole is not planned, fill a monolithic area, which will also serve as a floor in the garage.

In order to correctly link the building to the terrain, it is necessary to define at least one point in which the corner of the building will be located, and to break the building in relation to it. When breaking, it is necessary to check the wall dimensions not only along the perimeter, but also diagonally. Also, the garage can be attached to the finished buildings, which greatly simplifies the process of breaking down.

Installation of metal garage: the stages of construction work

The principle of building a metal garage is not very different from the generally accepted standards of most buildings.

floor and foundation of the garage

The observation pit in the garage is most often done first. After the foundation pit is ready, the formwork is installed inside and the space between the boards and the ground is poured with concrete after installation of the reinforcing mesh.

To fill the cushions under the garage, the upper layer of the earth is removed to a depth of about 10 cm, the pad is cleaned of debris and roots, sprinkled with clean sand, and rammed. After that, a layer of fine gravel is piled on top, a 10 mm grid is laid from the reinforcement and filled with a layer of concrete so that the finished pillow rises above the ground level by 10-15 cm. When choosing a place for the garage, the building is needed on a hill to prevent water from entering.

In general, it is much easier to concrete the floor for a metal garage than to do a similar job in a brick or stone building. Do not particularly zealous - the platform should be level, without visible bulges and cracks. Before the gate you need to make a small slope. After the site is ready, it is advisable to periodically water it with water for a week. Concrete will gain enough strength in about three weeks, of course, in the warm season. For pouring the floor will need about 2 to 4 cubic meters of concrete. Calculate the required amount of concrete is very simple: multiply the width, length and height of the pillow - we get the number in cubic meters.

garage assembly

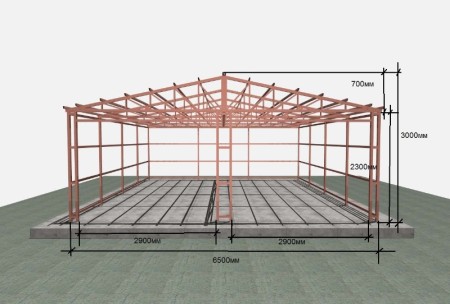

First, the frame is assembled. Vertical racks are connected to each other by cuts from below, from above and in the center. The frame for a metal garage is most often welded, although it is possible to join parts using fasteners. Particular attention should be given to the ceiling. The roof in metal garages is made gable, the roof frame is welded from the metal profile in the form of several triangular rafter elements.

After the frame is ready, it is sheathed from the outside with metal sheets. The sheets are welded to the frame or fixed with screws. In the latter case, the building can be easily disassembled if necessary.

installation of gates in metal garage

This is perhaps the most time-consuming and responsible part of the work, although you can buy ready-made gates. It would be advisable to install the simplest swing gates on a metal garage. The frame for the gate is welded from a metal corner or profile and welded to vertical posts.

The width of the gate itself should not be less than 2.5 meters. The gate is welded from the profile pipe and is covered with metal. Particular attention should be given to the selection and installation of locks. The choice of a lock for a garage is a topic for a separate publication, the choice is very large, the installation methods are numerous. Ideally, the garage should protect several locks, one main, and the second, blocking access to the keyhole of the main lock.

than to insulate the metal garage

Since the winter inside the metal garage will be, to put it mildly, cold, and in the summer unbearably hot, thermal insulation is necessary. Warm metal buildings with the same materials as brick - foam, mineral wool and other thermal insulation materials.

But to insulate a metal building, mineral wool is best suited as a fire-resistant material with good thermal insulation properties.

If you can not buy mineral wool, you can use polystyrene foam, but it is a combustible material that also releases toxic substances during ignition. From the inside, the insulation is covered with a finishing material. This can be a simple steel sheet, covered with a layer of primer, corrugated board, sheets of plywood or fiberboard.

arrangement of metal garage

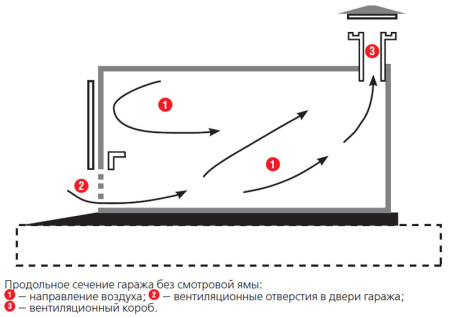

The garage is almost ready, there are a few small, but important details. First of all, it's ventilation. It is necessary to divert the products of the "life" of the car and maintain the indoor humidity optimum. The most optimal and simple option for a metal garage is a natural supply and exhaust ventilation system.

You can, of course, install a fan and make a forced ventilation system, but it is good only as a means of quickly ventilating the room, and the necessary microclimate must be maintained in the garage at all times.

For the device of natural ventilation the exhaust hole is made at the highest point of the wall, under the ceiling. The inlet opening is located at a height of 30-50 cm from the floor. The ventilation openings must be covered with grilles and located in view of the wind rose, the exhaust duct should be located in the direction to which the wind most often blows in your area.

To warm up the engine in the garage and do not get poisoned by exhaust gases, a rubber tube with a tip of noncombustible material is put on the exhaust pipe, the other end of the tube is taken out of the room.

With a competent layout and organization in a metal garage, you can store a lot of things, tools and even food for the winter. For comfortable work in the premises you need to bring electricity and provide heating in the winter. The simplest and most effective way to heat a metal garage is a modern wood burning stove, which is a full-fledged heater, with high efficiency and almost completely safe.

A warm and well-ventilated metal garage will serve as a decent cover for your car, will significantly extend its service life and protect you from thieves.

More details about the construction and process of building a metal garage can be found in the following video: