The decision to sew a house with a siding has quite good reasons - the material is reliable, having a decorative look, and most importantly - perfectly cope with its functions: protecting the walls of wooden buildings from the effects of atmospheric factors. Finishing siding of a wooden house can significantly improve the appearance of the building, even if it was erected long ago.

Content

Types of siding, their characteristics

Siding - facing facade material, a couple of decades ago, consumers almost did not know about its existence. The first to start siding production was the Americans, in the middle of the last century. Today in the network of building markets you can find three types of material: wooden, metal, vinyl.

The most popular is the vinyl material, which exceeds its own counterparts:

- wooden - practicality, simplicity of installation, unpretentiousness in service,

- metal - lower price.

Finishing wooden siding wooden house cost is considerable, in addition, the need for constant care, repair and painting, the replacement of dilapidated fragments did not contribute to the popularization of this variety. Although the material is natural and environmentally friendly, it has many significant drawbacks, the most important of which are the propensity to ignite and a relatively short life.

For siding of living quarters metal siding is not used, but it is quite suitable for finishing non-residential and industrial buildings. Among the advantages should be mentioned: a long service life, incombustibility, strength, a wide range of colors. The main disadvantages are: susceptibility to corrosion and heavy weight.

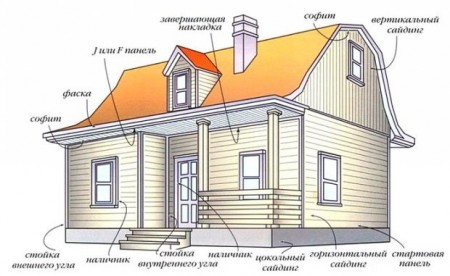

Most recently, a socle siding has been put on sale, designed to protect the base of buildings from the effects of moisture on them. The design of the siding of this kind is very similar to a beautiful stone or brickwork. After finishing with socle siding, the building becomes quite refined and attractive.

Vinyl siding is a PVC panel with a width of 20 to 25 cm and a length of up to 4 m. The material does not absorb moisture, which excludes its destruction when the temperature drops below 0 ° C, it is resistant to sunlight,

it is easily cleaned of contaminants,

The presence of many shades of material allows you to create facades with an interesting color solution.

For decoration of the facade of a wooden house with siding is suitable only a vinyl version of the material.

Each finishing panel consists of two layers: a base that supports the physical characteristics of the material and the protective coating.

Of the positive qualities of such finishes, one should remember:

- absence of additional care or treatment,

- service life is more than 50 years,

- the possibility of mounting on any surface,

- absence of threat of damage by putrefactive microorganisms, inconvenience to corrosion.

Step-by-step finishing with the facade siding

material calculation

The finishing of the house with the siding begins with the calculation of the material.

You can do this after the proper measurements of the walls on your own, if you are not sure about the correctness of the calculations, it is better to turn to specialists for help, experienced employees of construction companies will be easier to calculate the required number of panels and related materials.

It is necessary to take into account the main disadvantage of vinyl siding - since panels come in sizes 3.8 - 3.95 m, a large percentage of the material leaving for cutting may occur during installation.

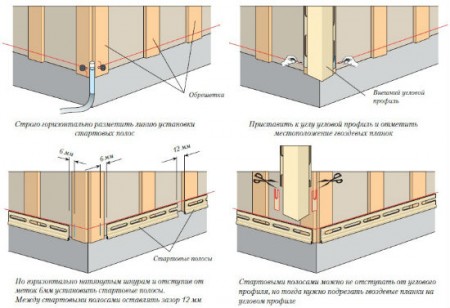

carcass construction

The first of two stages of finishing works is the construction of the frame. The installation of the battens will be a prerequisite if there are irregularities on the walls of the wooden house, or the walls were previously covered with other types of plating. Before starting work, the old sheathing, if any, should be removed. It is not necessary to mount a lath on new, even walls.

For the construction of the frame, you can use narrow boards or slats, most often - a beam of 50x30 mm. The boarding material should be treated with impregnations, fireproof and antibacterial. The guides should be positioned perpendicular to the direction of the finishing material sheets. Planks should be filled at a distance of 0.4 m from each other, along the entire perimeter of the house.

Most often, the house is finished with siding with insulation - an option when a space between the wall and the frame is laid layer of heat insulation material. This is the simplest way of exterior insulation of the walls of a wooden house. After laying the insulation, a layer of a windblasher is installed, which is a special film capable of letting steam out from inside the structure, but not allowing moisture from the street. The presence of a windbreaker guarantees a constant dryness of the heater. To fix the windbreaker, use a counter-rack 20x50 mm.

Sometimes a metal profile is used to mount the siding, such as for mounting drywall.

Mounting work on the metal profile is carried out as well as on the wooden beam.

Some useful tips

Regardless of the siding used during installation, you should follow these rules:

- installation of the plating should be postponed until the time when the wooden house will shrink,

- for cutting material, use a hacksaw or electric saw,

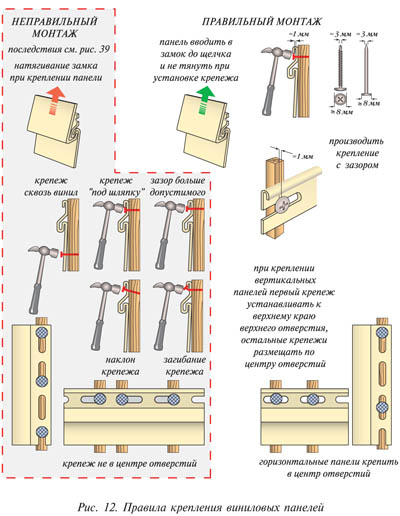

- as a fastener for panels, nails with a minimum length of 2 cm should be used, placed in the center of the elements,

- do not tighten the panels very tightly to the frame,

- after every 5 rows, the level should be checked by the correctness of their placement

- the installation should start from the center and move to the corners.

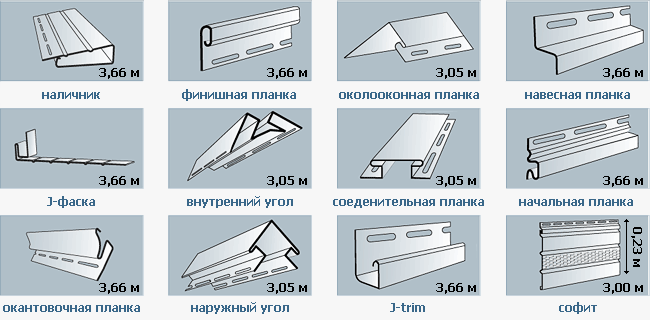

Horizontal version of the finish

The siding can be mounted vertically or horizontally when the wooden house is clad. In the variant with horizontal arrangement of panels, the start point of the installation is initially designated. To determine it, you can use a level or a plumb, such a point is usually higher by 5 cm than the lowest angle of the structure. Next, fix the initial siding panel and set the inner corners. At the junction of the walls, below the level of the starting plate, the inner corner is fixed. Nails are used to attach it to the upper and lower parts.

When installing the next corners, monitor how tightly they fit against the wall. If the length of the inner corner stand is insufficient, then from the top of the panel cut off 2 cm, the top panel is overlapped. External corners are mounted similarly to internal corners. After the assembly of the corners, the casing for the door and window openings is installed.

Observing the technology of lapping, the next row is set to the next row. Begin work from the back wall of the structure and move on to the facade. When installing panels near windows and doors, you may have to cut off excess material. First mark the cut point, then bend the material until it breaks. When installing the last row, it is required to fix the finish strip under the cornice.

Vertical finish

Similarly to the above, the vertical finishing of the wooden house with siding is performed. Installation of the starting plate is carried out with the aid of a plumb and level, then the inner and outer corners of the structure are assembled. The lower edge of the corners is aligned along the J-profile.

After checking the verticality of the first panel, set the last bar in the groove of the outer corner. If you have the skills to work with the simplest construction tools and the desire to save on finishing works, then you can do it yourself. The result will depend on the quality of the selected finishing material and on how responsible the performer will be working on the solution of the task.