The balcony of the last floor of multi-storey buildings can be called the territory of inspiration. High, far and the visibility of the horizon reveals the potential of the owners in the improvement of the balcony. The only thing that darkens the existence is the heavy snowfall and torrential rains that sprinkle and water the balcony.

Well, you need to urgently solve this by installing a reliable roof on the balcony.

Content

The design of the roofs of the balcony

Owners of balconies of the last floor of multi-storey houses are very often unhappy with the lack of a roof over the balcony. However, typical projects of multi-storey houses simply did not provide for the arrangement of roofs of this type.

What should be done to improve the roof on the balcony of the last floor? In order to equip the balcony and make a reliable roof, it must be borne in mind that the roof structure can have the following types:

• dependent construction

• independent design.

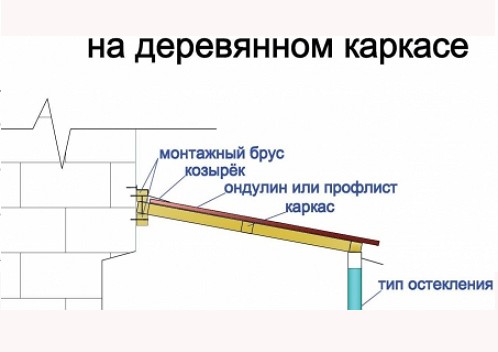

Dependent The roof construction is used in combination with supporting elements - it is a system of aluminum frames. Such a design is easy to install, because there are support elements and nothing more is needed to invent.

Independent the structure is a frame-bearing supporting frame, made of a metal corner. The metal corner is the base for fixing the crate and covering the roof.

Independence of the design provides additional opportunities for the improvement of the balcony and the roof in particular. For the improvement you can choose a different type of coating, profiles of the glazing system and overall dimensions, which no one and nothing limits. Therefore, the flight of imagination to create a roof on the balcony, nothing should in principle prevent. So, how can we make a roof on the balcony with our own hands?

What material can be used to make the roof

To make a roof on the balcony can be made of any material, this does not require the permission of the relevant authorities or neighbors.

The roof of the balcony is a small architectural form that does not require approval during design and installation.

To make the roof on the balcony use hard and soft materials, as well as a transparent coating.

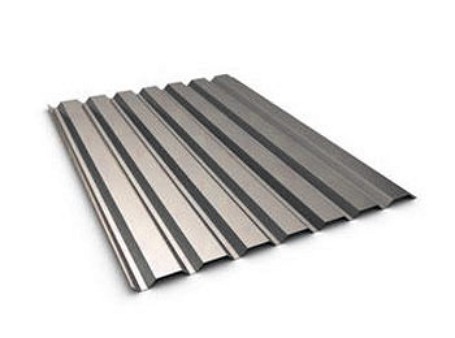

The most common type of coating is a variety of types of steel sheet, including corrugated sheet, corrugated sheet, galvanized. The choice of corrugated board for roof improvement is simple, because it is possible to attach to any roof structure, dependent and independent. In addition, the rigidity of the construction of corrugated board or corrugated sheet can withstand snow and wind loads. However, the significant noise level of rain drops on the roof can overshadow the existence.

Therefore, the development of a sturdy structure for fastening rigid materials should stand on the pivot place for the improvement of the balcony.

Soft roofing materials for the balcony under the roof are also used actively, as well as rigid. Among the soft materials the greatest preference was given to ondulin. Ondulin, in comparison with rigid corrugated board, is an excellent noise isolator. It is worth more than the metal sheets, but it insulates the roof of the balcony from excessive noise.

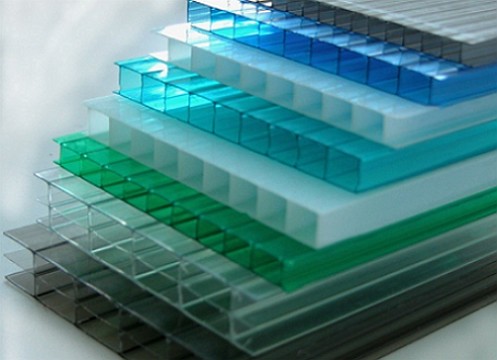

Transparent covering of the roof looks always impressive. For the production of this type of roof, double-glazed windows or cellular polycarbonate are used. Double-glazed windows for roof installation are preferable to use from tempered glass. Polycarbonate honeycomb is preferable to use in the "warm" version of the glazing. A distinctive characteristic of cellular polycarbonate is the increased resistance to UV radiation, which prevents the destruction of the structure of the material.

How to build your own hands on the roof on the balcony

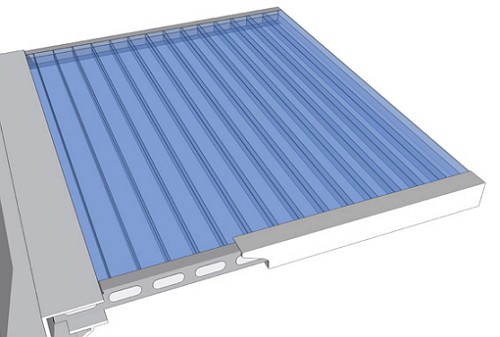

The optimal option for erecting the roof of the balcony is the construction of the corrugated board. The roof structure assumes a supporting frame, on which the crate is fixed on top and the coating is laid.

profiled roof

Fabrication of the supporting frame

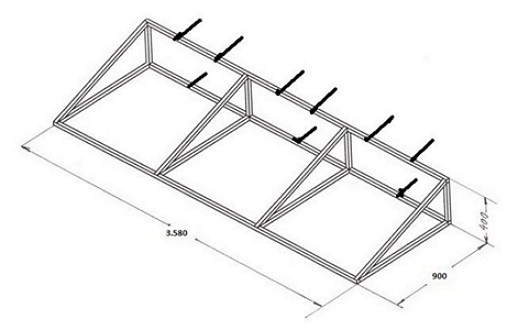

For the manufacture of the roof frame is used corner metal, for example corner number 60. Steel corners are welded in the form of a rectangular triangle.

The necessary number of corners (support trusses) is determined according to the length of the balcony, with the recommended pitch of 80 -100 cm. The number of corners can be from 4 to 6 pcs. Corners must be prepared before the installation process. Finished corners are fixed to the wall with a smaller side using anchoring bolts 70-100 mm in length.

Anchor is buried in the working surface of the wall to a depth of 80 mm. If the working surface is a brickwork, use anchors with a special wedge pin, which fixes the position of the fasteners and the frame. On the formed support frame, a crate of 40x40 mm lumber is constructed, treated with a special antiseptic. In the lagging laths and metal corners, holes must be made through beforehand, through which the covering will be fixed.

Fastening of corrugated board to the prepared skeleton

For fixing the corrugated board, it is better to give preference to special self-tapping screws with a sealing washer. The joining of the corrugated board is made lapped taking into account the value of one wave. For one square meter of the roof, 8 to 12 anchorage points are provided.

After fixing the sheets of corrugated board to the crate, the resulting cracks between the wall and the sheets are filled with mounting foam from the inside. External slits are sealed with a solution of cement and treated with a sealant.

How to build a roof on the balcony will help this video.

The construction of the roof on the balcony of cellular polycarbonate, possibly, also produce independently.

polycarbonate roof

To create a roof made of polycarbonate honeycomb, panels of 700 and 1050 mm in width, as well as profiles of "HP", the thickness of the profiles depends on the thickness of polycarbonate sheets of 6, 8, 10 and 16 mm.

The process of manufacturing a supporting frame for laying a coating is similar to the process of manufacturing a framework for corrugated board.

When creating a polycarbonate roof, the stiffeners of the panels must be positioned vertically along the length of the panel. On the bearing supports of the roof frame, the edges of the panels are arranged along the length. Longitudinal frame supports are installed in steps of 700 - 1000 mm. Connecting polycarbonate sheets to each other and attaching them to the longitudinal supports use connecting profiles. Fastening to transverse lathing of panels is made by screws equipped with thermowells.

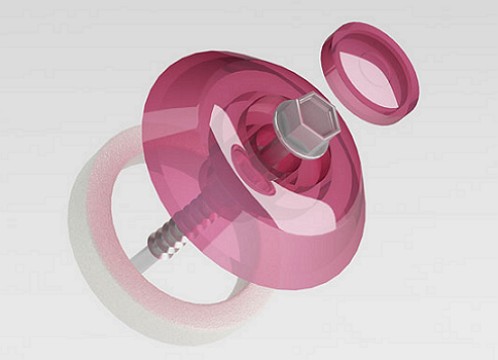

The thermoshow is a fastening element consisting of:

• washers plastic with a foot

• washers for sealing

• the cover is snap-fastened.

The height of the plastic washer with a foot corresponds to the thickness of the polycarbonate panel. The shank of the thermowell in the working position rests against the carcass surface, thus preventing the possibility of crushing the expensive panel.

Therefore, to compensate for the expansion, it is recommended that the holes in the panel be made 2 mm larger than the diameter of the stem.

The main nuance, which must be paid attention during installation, is the sealing of the ends of polycarbonate panels. When the panels are tilted on the roof of the balcony, the upper ends are sealed using an aluminum self-adhesive tape, for the lower ends of the panels a perforated tape is used that will provide a drain of condensate and will prevent moisture penetration.

In this case, high-tech cellular polycarbonate will provide reliable protection of the roof of the balcony.

In the meantime, build a visor of polycarbonate with your own hands, perhaps it will be a test job before installing the roof over the balcony.