Well-groomed and, according to the rules, the lined plinth or the facade of the house immediately attracts attention. The most attractive for the facing is the original coloring and texture of the socle tile. What are the secrets and nuances of the technology of slab cladding for the socle?

Content

For which the lining of the plinth is made

The outer lower belt of the facade and the foundation of the private house is the socle. The main purpose of the socle is to protect the house from damage, moisture and pollution.

Traditionally, the socle belt is lined with strong and durable materials, such as socle tile, clinker and stone. For each facing material, there is a proprietary technology that makes it as simple as possible to protect the facade and walls of the house.

Most cladding technologies are available to implement the ideas of protecting the facade for hand-made execution. The main thing is that it is prudent to choose a facing tile and to study the technology of laying. The question: "Why are the base plated?" Will find the answer.

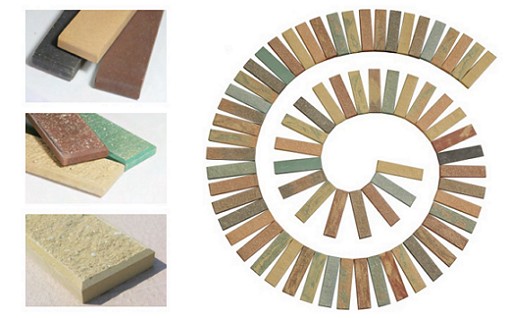

Types of tiles for the lining of the plinth

The following technologies and materials are used for the lining of the socle:

• make plastering with subsequent painting

• trim the facade of the socle with metal siding and siding

• make lining using artificial stone

• using clinker brick

• tiled.

Manufacturers produce facing tile materials based on mixtures: expanded polystyrene, cement-stone and asbestos-cement. Installation and lining of the plinth base is carried out with the help of moisture resistant quick-cooking solutions.

It is thanks to the quality adhesive solution and the availability of the installation that it is not difficult to make the facing. However, before the beginning of the cladding, it is necessary to make preliminary work on surface preparation and protection of the plinth.

How to make the base of the house

To make the lining of the socle can be by two technologies: glutinous and glutinous.

adhesive coating technology

This technology of lining is the use of a special adhesive composition. It is used for socles up to 50-70 cm in height and a weight of basement tiles up to 4 kg each. If the plinth has a significant height, and tiles are a significant weight, then it is more appropriate to use a lath for fixing the tiles.

Facing the socle of the private house in glue technology consists of the stages:

• preparatory

• calculation of tile rows

• primer and adhesive surface preparation

• application of adhesive

• laying tiles

• Verification of vertical stacking

• Grouting joints.

surface preparation and protection of the plinth before installation

The base of the plinth surface must have a firm and even surface. The surface is cleaned of dirt, stains and efflorescence. Clearly pronounced irregularities with lumps and depressions are removed by pouring or filling with an equalizing compound.

Then the surface is impregnated with a primer emulsion. This reduces the water absorption of the base of the surface to eliminate the retention of part of the moisture from the adhesive solution.

To protect the surface of the socle of the porous structure, it is necessary to carry out the hydrophobizator treatment.

what are water repellents

Hydrophobizers for the protection of the socle are compositions on a silicone or acrylic base, which, when treated with a porous surface (concrete, brick, sandstone), give it water repellent properties.

The result of the treatment is the creation of a special water barrier, capable of penetrating into the cracks and pores of the base of the socle. Moreover, on the protected surface, water flows freely and leaves no traces.

As waterproofing agents for protecting the socle, Aquasil, Tiprom, WEPOST LUXE, Crystallisol can be used. Apply hydrophobizors in the traditional way with a sprayer and a roller.

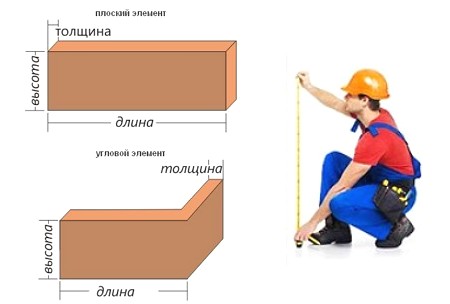

calculation of tile plinth rows

Calculation of the tile rows of the plinth and the levels of masonry are determined thus:

the height of the socle must be divided by the width of the tile. It is necessary to take into account the width of the double seam.

For example, for a socle with a height of 400 mm, a socle tile with a width of 120 mm was chosen. Dividing 400 by 120 mm, we get the number of rows 3. To create a horizontal landmark along the length of the cap, the starting bar or profile is beaten.

primer and glue preparation

Before laying the tiles for the base of the house produce a traditional surface primer and adhesive preparation.

Before the preparation of the adhesive solution, it is necessary to trace the conformity of the actual conditions of the masonry and the recommendations of the manufacturer. Recall that this is the level of humidity and temperature.

It will not hurt to re-study the recommendations for preparing a glue solution. The controversial question: "How to apply glue: on the wall and tile at the same time?", It's easy to decide. On the tile it's for sure! Experts recommend that when laying basement tiles, given its significant weight, apply glue solution to the tile and the wall.

To prepare the glutinous solution, the dry mixture is poured into a container of water. The mixture is then mixed by hand or mechanically. After stirring, the adhesive solution is left for 10 minutes to completely dissolve the chemical components of the dry composition. The adhesive solution is applied to the work surface for 10-30 minutes.

During this time interval, the solution retains its performance characteristics. The classic water-to-mix ratio is 4.5 to 5.0 liters per pack of 25 kg of dry mix.

adhesive application

It is recommended to apply the adhesive on the surface of 1 square meter with a spatula with teeth. Select a spatula in accordance with the size of the tiles. The thickness of the adhesive layer, applied by a notched trowel, can be from 5-8 mm.

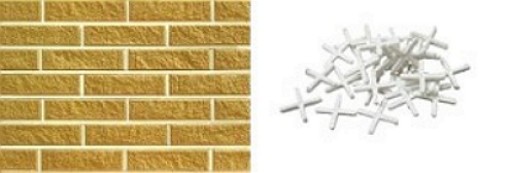

laying tiles

Laying the tiles for the base of the house starts from the outer corner. This rule applies to almost all types of tiles, including clinker tiles. Tile gently squeezed with both hands in the adhesive layer, leaving the necessary thickness of the seam.

In the laid tiles of one row insert remote crosses, with which you can adjust the location of the tiles, until the glue dries.

In the process of laying tiles, it is necessary to control the verticality and quality of laying by means of a level.

grouting

After the final drying of the adhesive solution and the time necessary for the "tasted" tiles on the plinth, grouting the joints. The dry trowelling mixture is prepared in the form of a thick solution.

The grout solution is applied by means of a rubber half-hook. The direction of application of the grouting is obliquely relative to the seam. After the grout has dried in the joint, the plinth tile is cleaned with a damp sponge.

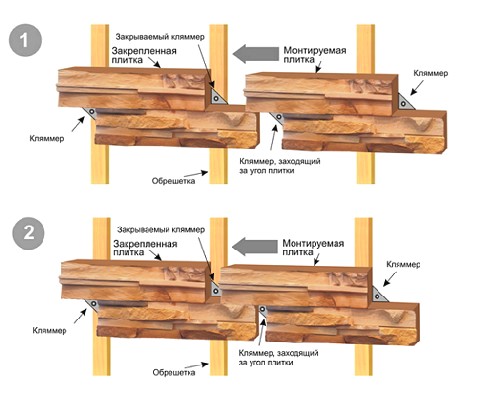

Glue-free lining technology

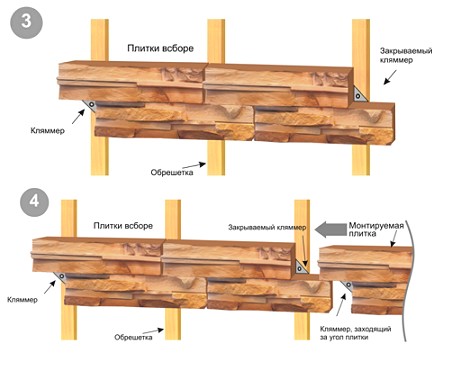

Bezklevaya technology is based on the erection of a vertical cladding, on which it is planned to fasten the tile. Vertical crate is erected in the traditional way with a step of 50 cm.

The dimensions of the step of the battens are chosen from the calculation of the use of: the basement tile CSC 250x20x120, the basement brick CSC 250x35x120 or the tiles facade PFT PP 250x16x65.

After the preparation and installation of the battens, the installation of the tiles begins with the lower left corner of the facing surface. The first tile is fixed with galvanized screws.

Ordinary elements are fastened with a clamp that extends beyond the edge of the previous tile. Fix the tile in place with a screw.