Prices for strong spirits are rising, bottles of alcohol of doubtful quality are often found, which even specialists can not recognize without conducting an examination in the laboratory. Therefore, people often have a fair question: is it not worth it to organize at home a small production of alcohol for our own needs? In addition, the cost of homemade moonshine is a mere penny compared to the prices for vodka, which the state dictates to us.

Content

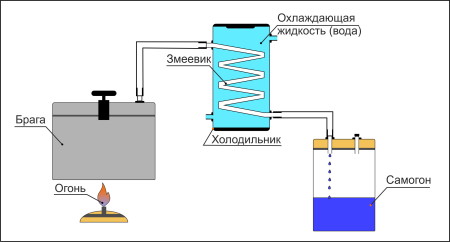

The principle of the brewing apparatus

Moonshine is a drink with a high degree of alcohol content, obtained by distilling an alcohol-containing liquid.

To obtain moonshine, the brew containing alcohol in its composition is placed in a closed container (a distillation cube) and heated. When heated to a certain temperature, low-temperature fractions, including alcohol, begin to evaporate.

The separated vapor with a high content of ethyl alcohol through the connecting tube enters the heat exchanger, where heat exchange takes place between the hot steam and the cold water that cools it. As a result of cooling the steam, a condensation process takes place, i.e. transition of a substance from a gaseous state to a liquid state. The alcohol-containing liquid, i.e. moonshine, gravity is collected in a separate container.

Thus, to obtain a liquid with a high alcohol content (moonshine), a device comprising only 2 elements is sufficient:

- heated distillation cube;

- heat exchanger.

In a home-brewed apparatus, a heat exchanger is often called a refrigerator.

Self-contained devices have the following advantages:

- simplicity of design;

- low cost of the product.

But moonshine machines are inherent and disadvantages:

- distillation of toxic methyl at the beginning and end of the distillation;

- the impossibility of complete purification of the product from fusel and essential oils.

To reduce the content of foreign substances, such as essential oils and fusel oils, and, consequently, to improve the quality of the product obtained, re-distillation is carried out in the brewer's own, and additional elements such as a dry cell and a bubbler are often included in the brewing apparatus.

Safety and fire safety regulations for distillation

For the effective operation of the home-brewed machine, its leaktightness must be ensured, therefore, an excessive pressure will be created inside the distillation cube when heated, which under certain conditions can lead to rupture of the container and the ingress of hot berg and steam onto the human body. Therefore, when using the brewing apparatus, it is necessary to ensure that the temperature regime is maintained and the coil, connecting pipes and hoses are not clogged with the brag.

The device of the moonshine

The main mandatory attributes of the moonshine are the following:

boiling cube

Distillation cube is the capacity in which the brew is heated up to the evaporation of light fractions.

Very popular with home-cookers are pressure cookers, since they were originally designed for work under pressure, they have a hermetically sealed cover, into which it is quite easy to cut a steam pipe. A significant disadvantage of the home-made apparatus from the pressure cooker is their insignificant capacity, so it is impossible to obtain a large amount of product at one time.

Along with pressure cookers, 40 liter aluminum milk cans are equally in demand. They are also sealed and well suited as a still cube.

Most often, distillation cubes are made of aluminum, but this metal can react with brag. The most suitable containers are materials resistant to acids and alcohols, for example, food grade stainless steel, titanium or copper, but their cost will be much higher than aluminum.

Often, as a container for the moonshine, enameled dishes are used. Enamel is resistant to the action of substances that make up the berg, and if the surface does not have chips and scratches, then such a device can last a fairly long time. The disadvantage of such utensils is the difficulty with hose connection and sealing.

The capacity of the distillation cube must have a well-sealed and at the same time easy-detachable cover of sufficient diameter for maintenance after use. Experienced home-brewers consider the optimal cube capacity in the range from 25 to 35 liters.

fridge

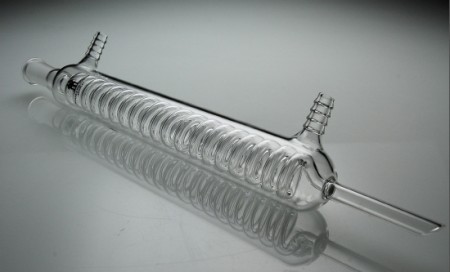

The refrigerator of the moonshine is designed to cool the steam produced in the distillation cube and to condense it into the finished product. The simplest refrigerator is a tube for steam, which is located inside a container with a cooling liquid or ice. For more efficient cooling, instead of a straight tube, it is advisable to use a coil - a tube wound in the form of a spiral. The capacity in which the coil is placed can be of two main types.

The first option is a large open container in which cold water is poured. As the water is heated, the water in the tank is replaced with a cold one, and in winter, snow or ice is often added to the water. Such a refrigerator is mainly used in the absence of water supply and is characterized by large dimensions.

A small flowing cooler differs through which the cooling liquid flows. The coil is located inside a small closed container with two nozzles. Through one nozzle inside the container cold water is supplied to cool the steam in the coil, and the other is drained by steam heated by steam. The refrigerator with the circulation differs in small dimensions, is more often used by tenants of apartments and has a significant drawback: a significant consumption of cold water, which means an increase in payment.

There are refrigerators with a coil, made of fine laboratory glass. Glass coolers are small, quite effective, but have a very big drawback - they are extremely fragile.

If the external capacity of the refrigerator can be made of any suitable waterproof material, not excluding plastic, then the coil itself should be resistant to alcohol and acids. For better condensation of steam into alcohol, the coil material must have as much as possible aboutthermal conductivity. Of the available materials, these properties are possessed by copper. Next in the row of thermal conductivity is aluminum, then - food stainless steel. Most often, the coil is made from a copper tube, especially since copper is easily processed and simply soldered.

thermometer

The thermometer does not belong to the obligatory elements, but the brags, and then the resulting steam, contain in its composition a multitude of chemical compounds and each of them has its own boiling point, different volatility, i.e. the ability to evaporate.

It is known that at normal atmospheric pressure water boils at a temperature of +100ºC, while ethyl alcohol + 78.3ºC. During distillation, a temperature close to the boiling point of the alcohol should be maintained so that only its vapor condenses in the refrigerator. At a temperature above +100ºC all the constituent brags will be converted into steam and the sense of distillation is lost. Therefore, it is recommended to equip the moonshine with a thermometer.

To install any type of thermometer suitable: liquid, mechanical (spiral or bimetallic) or electronic.

In the manufacture of the apparatus, it is more convenient to mount the thermometer in a tank of a still, but experience shows that more accurate values can be obtained by measuring the vapor temperature directly in the evaporator.

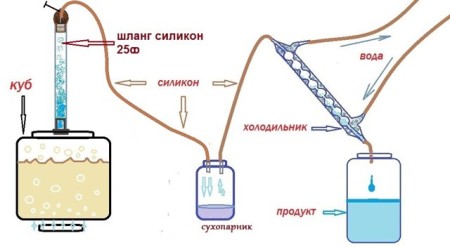

dry-cup

Beginners underestimate the dry cell in the moonshine and why they do not need to know, because the device is functioning properly without it.

However, specialists who have a lot of experience in brewing, try to supplement their designs with a drywall to improve the quality of the product. It is believed that the use of a drywall in terms of cleaning efficiency can be compared to double distillation.

As a result of fermentation of raw materials and subsequent heating, in addition to the alcohol required, a large number of different compounds are formed, some of which are dangerous for human health and life. These include methyl, fusel oils, acetic aldehyde, various ethers and some other substances. In addition to harm to the body, these impurities significantly impair the taste of the product. To achieve acceptable quality at home, you can use multiple distillation.

The drywall is installed between the dishes with a brag and a heat exchanger. It is a tank with an inlet and an outlet tube cut into the top. It is necessary that the container is opened or opened. In the lower part of it you can cut a drain cock for the liquid that has accumulated on the bottom.

The use of a so-called dry-cellar already during the first distillation helps to purify and improve the product obtained. With intense boiling, the barge is often blown out through the connecting pipe into the coil, thereby hammering the system, and some of the brew can get into the moonshine. The drywall eliminates clogging of the tubes, moreover, the steam is cooled slightly in the vessel, which causes the condensation of a part of foreign products. At the bottom of the dry box, a liquid with an unpleasant odor accumulates, indicating an additional cleaning of the moonshine.

In addition to the additional cleaning of the moonshine, the dry cell can be used to impart a flavor to the end product, for which an aroma can be placed inside the device, for example, an orange peel, lemon peel, coffee, etc.

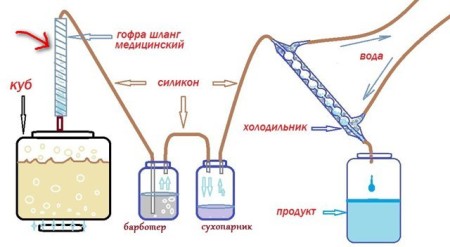

bubbler

The bubbler, together with the dry cell, is not part of the ordinary brewing apparatus, but is often used in both artisanal and industrial designs. In fact, these two devices are very similar in design and are designed for additional cleaning of moonshine.

The difference of the bubbler design from the dry cell consists in the fact that the inlet tube is lowered almost to the bottom of the container, and the output tube is short. Before starting the device in a container, it is desirable to pour a little water to create a liquid seal. During the distillation, steam passes through a layer of liquid in the tank, is partially released from the side connections and exits through a short tube. Similarly to a dry cell, the bubbler can be used to flavor moonshine.

How to make a home-made device at home (step by step instruction)

To make a classic apparatus at home is not a big deal, drawings of moonshine devices of various sizes, shapes and configurations can easily be found on the net. As a rule, such devices are collected from materials that are literally at hand: pressure cookers, pans, cans, glass jars. Probably only the manufacture of a serpentine with its own hands causes some problems, since not always the right materials will be found at home, and winding turns requires some skill.

It is easier to make an indissoluble homemade machine, hard-wired or welded all the elements into one, but in this form it will take up too much space. Therefore, it is recommended to make the structure collapsible and use detachable connections, for example, fittings, flexible hoses.

how to make a distillation cube

No moonshine can function without a still cube. Its role can play almost any ready-to-close container, starting from a pressure cooker and ending with a can.

The households still have old aluminum cans of 40 liters capacity. They have proven themselves well in terms of capacity, corrosion resistance, serviceability, tightness and are well suited for use as a distillation cube with the output of moonshine almost an order of magnitude more than a pressure cooker. The completion of the can for the home-brewed device, heated with gas, will be minimal.

In the lid of the can, a hole is drilled with a large drill bit for metal and bored with a round file to the desired diameter. A threaded connection with a 1/2 "thread is inserted into the hole and clamped with a nut through the food silicone gasket.

Although electronic thermometers are more accurate, it is easier and more convenient to mount any mechanical bimetal thermometer with a maximum measurement temperature of 120ºC to the distillation cube. For it, an opening of the required diameter is drilled in the upper part of the container, a thermometer is inserted and, using the supplied food silicone gasket, it is pressed with a nut.

The sealing of the lid is ensured by a round gasket made of rubber, but when distilled, alcohol dissolves the rubber, which gives a bitter taste to moonshine. To get rid of this, you can tightly wrap the pad with Teflon tape and the resulting structure boil for a while in the water to remove lubricant, fats and other excess substances from it. After that, the gasket can be safely applied for sealing.

how to make a connecting hose

To connect the distillation cube and the dry cell it is recommended to use a flexible gas hose bellows type (metal hose) made of stainless steel with a nut and a 1/2 "nozzle. It interacts less with alcohol vapors, is easy to assemble and disassemble.

The length of the hose is chosen on the basis of necessity.

how to make a dry cell or bubbler

In the factory-made apparatus, the dry cell and the bubbler are made of food grade stainless steel, which is not easy to replicate without equipment and corresponding skills. At home, a glass jar with a screwed tin lid and two chutes are suitable for making a dry cell or bubbler.

Marker should draw on the tin cans two circles, equal to the diameter of the fittings, and then in these places make holes. This can be done, for example, with an awl, scratching the thin metal of the lid along the drawn circle. Make a small hole and round the nail file cut the lid along the marker lines or use an engraver for these purposes.

Plugs are inserted into the resulting holes and through nuts of food silicone clamped with nuts. If there are no sealing pads, you can rewind the fum-tape or, before mounting the fittings, apply a small layer of glue, called "cold welding", to the edges of the holes on both sides of the cover.

The bubbler has a similar design and differs from the dry cell by only one elongated tube. For the manufacture of the bambotter, a piece of a copper tube of the appropriate diameter can be soldered to the nipple. The length should be chosen in such a way that its end does not reach the bottom of the jar a few millimeters.

how to make a refrigerator

The most laborious process when creating a home-made apparatus is the manufacture of a refrigerator. It is recommended to use a copper tube with an outer diameter of 1.0-1.4 cm and a length of 150-200 cm and a wall thickness of about 0.1 cm. Vertical placement of the coil with an upper steam supply and a lower coolant supply (for a running cooler) is preferable.

The metal tube is flattened during bending. In order not to happen when winding the turns, the entire volume of the tube is filled with sand, and the ends of the tubes are clogged with any stoppers so that the sand does not spill out.

The tube is wound on a round mandrel with an external diameter of 35-50 mm with a pitch (distance between the center of the tube) 12 mm. After winding the coil, plugs are removed, sand is poured out, and the tube is washed with water.

The capacity of the flow-through refrigerator, into which the coil is placed, can be made of any water-resistant material. You can use a metal jar with a lid, for example, a can of paint. On the side of the can of the top and bottom make holes for the inlet and outlet water fittings, and in the bottom and cover of the tin can - holes for the coil. The connection can be fixed by soldering with a gas burner.

Insert the coil into the can, passing the end of the tube into the hole. On the second end of the coil is put on the lid and tightly closed. To fix the coil in the bank is also worth soldering.

Do not make large holes for the fittings and tubes of the coil, otherwise they will be difficult to solder. Who does not know how to use a gas burner or soldering iron, the sealing can be done with cold welding.

Self-made devices of industrial production

The law also does not prohibit the manufacture and sale of moonshine machines for own use. For those who can not or do not want to mess around with the construction of the moonshine, on sale you can find devices for every taste and any purse, even those that drive moonshine almost on an industrial scale.

The bulk of the market for home-produced devices belongs to domestic manufacturers, but if you want, you can also find imported designs. A large number of models are produced: from the simplest to the luxury class with rectification. Some devices are assembled as a designer: depending on the needs of the consumer, you can choose the type and size of the distillation cube, refrigerator, choose a dry-cell, a bubbler, etc.

Among the connoisseurs of moonshine, the machines under the trade marks "Luxstal", "Magarych", "Alkovar", "Dobrovar", "Dobry Zhar" and others are in great demand among connoisseurs of moonshine. In the top of the best moonshine vehicles in 2017 included models such as "Dobpy Zhap Ekstpa lukc", "Luxstal-3", "Doctor Guber-2017", "Phoenix Zenith".

Before using a self-made construction, it is worthwhile to test: instead of brewing, pour water and check whether there will be any problems in the operation of the device.

The article deals only with the device and the operating principle of the apparatus, and the process of making moonshine itself is a whole art and subject of a separate article.