Did you know that waterproofing is a strategically important weapon in the battle for comfortable living conditions in an apartment or in a private house? Thanks to the waterproofing in the bathroom, you can eliminate the problems that arise. Just do not forget that usually in the modern bathroom of a private house provide for the installation of a plastic window. Plastic window in the bathroom of a private house allows you to save electricity during the daytime. In addition, the plastic window makes the bathroom modern and stylish. But, the installation of a plastic window provides for additional waterproofing. True, modern waterproofing has nothing in common with roofing paper and bitumen. Do you want to make waterproofing with your hands using quality and affordable materials?

Content

On the need for waterproofing measures

Daily intensive maintenance of the bathroom requires improving the waterproofing characteristics of the room. A significant level of humidity, penetrating steam and settling condensate over time can cause significant damage to the finish of the bathroom.

To avoid this, it is necessary to waterproof the bathroom as early as possible. How to properly implement waterproofing measures?

Which surfaces should be protected with a waterproofing layer

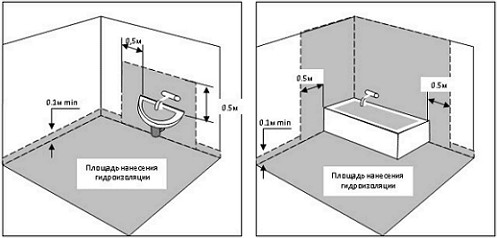

Ideal option for waterproofing the bathroom can be considered the treatment of working surfaces that are most susceptible to moisture and steam. These are the so-called "wet" and "wet" zones. In the "wet" zone are the walls and floor located directly in the radius of operation of the bathtubs, wash basins and toilets.

The "wet" zone includes other surfaces of the room, located in the radius of exposure to water and steam at a distance of more than 50 cm from the source of exposure. Undoubtedly, the floor surface belongs to the "special attention zone", so the waterproofing of the floors in the bathrooms can be considered a top priority. The intensity of exposure to the surface of walls and floors in the "wet" can cause significant inconvenience, if at the time do not produce waterproofing measures.

Technology of waterproofing the bathroom

how to make a waterproofing floor in the bathroom

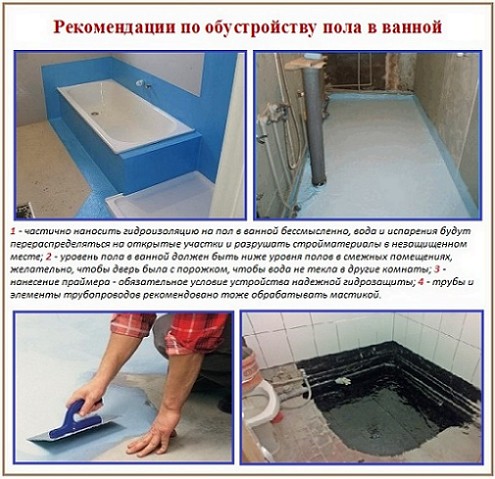

Beforehand, before working, the floor in the bathroom should be cleaned of dust and small debris. Existing joints of the floor with walls are sealed with a waterproofing tape. Then, the floor surface is primed, which significantly improves the quality of the subsequent application of the waterproofing. It is recommended to purchase ready-made solutions for this purpose.

Waterproofing liquid is applied using a roller, spatula or brush. In this case, the composition is applied in two layers, with a time difference of 6 hours. If the floor of the bathroom is concrete, it is recommended to use impregnation. Waterproofing with the use of impregnation is also applied to the walls at a distance of 30 cm from the floor surface. All work on screeding or laying of tiles is recommended to be done in a day after the end of the waterproofing of the floor.

Helpful Tips

Waterproofing compounds are completely "compatible" with different types of glue for tiles. As a rule, there are no complications in the subsequent laying of tiles. Perhaps you do not trust the waterproofing compound, then make an experiment. Put the test fragment of the composition on the floor and leave for 8-10 hours. If there is no deformation of the applied layer or cracking, you can safely start the waterproofing of the bathroom floor with your own hands.

we produce waterproofing walls in the bathroom

The process of waterproofing the walls in the bathroom is practically the same as the technology of waterproofing the floor. The only condition is the correct application of liquid waterproofing from the corners of the walls. If, during the waterproofing of the floor, it is necessary to seal joints between the floor and the wall, then, when sealing the walls, joints between the walls are also glued.

It is also necessary to use sealing corners, glued to the corners of the walls. For protruding sections of pipes or grilles, cuffs are used. They should also be covered with a waterproofing compound. Waterproofing should be applied in two layers with an interval for drying the previous layer about 4 hours.

Materials intended for waterproofing

Methods of applying the waterproofing layer conditionally divided the materials into the following types:

• Overlay waterproofing

• coating compositions.

Oakleychnoye waterproofing and coatings are selected for the accelerated completion of measures for waterproofing and the characteristics of the bathroom.

The existing method of waterproofing bathrooms and bathrooms using roll bituminous materials of the last century is difficult for self-sealing, because it requires certain skills and a special burner. Therefore, waterproofing with application of pasting materials or coating compositions is most preferable for carrying out work independently.

waterproofing

Modern waterproofing pasting type has left in the past bitumen filler. Today, roll-type materials are produced in the form of easily spreadable flexible fiberglass or fiberglass, based on elastic polyester. Self-adhesive insulation layer is easy to install and does not require waiting for hardening of the working surface.

A special feature is the complete fixation of adhesive strips. Adhesive provides only reliable adhesion to the working surface of the floor, but also improves adhesion. Thanks to such positive qualities, finishing works on laying tiles on walls or floors can be carried out in parallel with waterproofing works.

Helpful Tips

Use self-adhesive waterproofing materials okleychnogo type is simple. It is enough to separate the protective film from the strip, which is preliminarily cut to the desired size. Leaders oklechnoy waterproofing can be considered:

• geomembranes of high and low pressure polyethylene NAUE

• sealing tapes MAPEI-Dichtband

• self-adhesive waterproofing CERESIT ВТ21, ВТ12, ВТ85.

The story about the materials for the waterproofing of the bathroom will be incomplete if you do not pay attention to the lubricating compositions that are most in demand during the work.

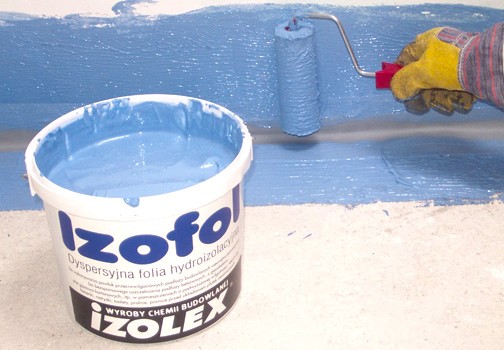

coating compositions for waterproofing the bathroom

Along with the materials oklechnogo type in demand are considered lubricants. Compositions of lubricating waterproofing are produced in the form of finished dry formulations, pastes or mastics. Paste or liquid waterproofing for the bathroom is ready for use. The liquid mixture is applied with a wide brush or spatula with teeth.

And, note that the main characteristic - the consistency of the lubricant composition is able to differentiate the scope of application. This waterproofing the desired thickness of a single layer (1.0 to 1.5 mm) and the creation of a screed. The possibilities of using multi-layer waterproofing with reinforcing mesh allow to achieve good results.

Helpful Tips

The coating and pasting materials are applied to a pre-prepared working surface. Naturally, the question arises: "Which material is preferable to use as a primer, impregnation or emulsion?". Especially interested are those who produce waterproofing of the bathroom under the tile.

We will suggest that in addition to the primer paint Ceresit CT16, intended for the preparation of the base of bathrooms for the subsequent painting or tiling, the following primers and mastics exist:

• ASOFLEX-P2M-BODEN (SCHOMBURG)

• HERMO-BUTYL-2M-U

• SOPRO EDF 525

• TRIBLOCK (TM MAPEI)

• MAPEGUM WPS (TM MAPEI).

How is waterproofing the floor using SOPRO EDF 525, will tell this video.