It is known that the location of the boiler room will inevitably involve mandatory requirements for existing and existing regulatory documents. To avoid negative situations and troubles in communicating with energy surveillance organizations, it is necessary to comply with these requirements. However, in practice, the reconstruction or re-planning of a house with the introduction of a boiler room on gas can acquire the status of a long-term construction. As always, useful advice of specialists and masters to help you.

Content

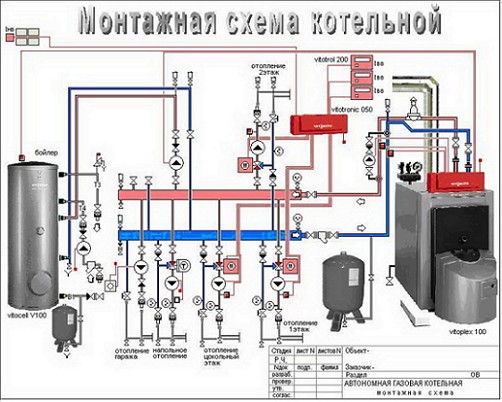

The project of a boiler house in a private house

Intending to create a gas boiler house, it is necessary to be guided by the regulations and requirements. Let us suggest that the normative base of the boiler house arrangement in private houses is SNiP 42-01-2002.

The basic (general) provisions of the document stipulate the requirements for planning and design solutions that accurately and fully provide information on the components of the gas boiler house:

- volume and height of a typical room

- calculated capacity of a gas boiler or unit

- calculation of ventilation volume

- the correct equipment of doors and windows.

Of course, the best option for the boiler room is the help of representatives of the gas company, who on a daily basis have a clear understanding of the rules for installing a gas boiler.

According to the norms and rules, the design of the boiler room will be included in the complex of measures for the boiler room installation: the general plan of the house and the boiler room, information about the device and the material of the walls, ceiling, floor and existing ventilation and insulation systems.

However, this does not prevent us from studying useful advice on boiler room layout, recommended locations for entering the gas main, the location of the doors and the requirements for the piping of the boiler unit.

Helpful Tips

Recall that gas boilers and units are classified as VO and PO equipment, therefore installation of floor and wall mounted boilers is regulated by regulatory documents and standards. The fulfillment of requirements must be taken into account at the design stage or the selection of the finished boiler room.

With the transition to natural fuels and boilers with a closed firebox, gas boilers are allowed to be equipped in any room, including basement and attic rooms. And the total capacity of water-heating or heating boilers can reach 200 kW.

Basic requirements

requirements for the gas boiler room

According to the regulatory documents and instructions for the boiler house, a separate room S is allocated at least 4 sq.m. per 1 boiler with a minimum distance from the front of the unit to the opposite wall of 1 m of the room. These requirements apply to the placement of boilers in a built-in room, however, it does not hurt to remember that it is forbidden to place gas equipment in rooms that are combined with living rooms.

The equipment is installed on a solid and level base made of non-flammable and waterproof materials (cement-sand screed, tiles). The ceiling and walls of the room with a height of at least 2.0 m are made of non-combustible materials, eliminating flammable materials.

Ideal - tiles or plastered walls. The width of the doorway of the room should be 0,8-0,9 m, the dimensions of the outward window are determined by the room volume - 0,3 sq.m / 10 cubic meters.

For normal operation of the gas equipment, free access to the units of the unit and the chimney is ensured.

doors of the gas boiler house, which to choose

To the entrance door of the boiler house, conditions are stipulated for the possibility of creating an air inflow inside by a vent hole in the lower part of the door leaf. To place a small area is enough to create a gap between the floor and the canvas.

When choosing a door to a gas boiler room, it is recommended to pay attention to the standard dimensions of the door leaf 800x2000 mm, the shape of the box profile and the profile pipe material (50x25 mm or 40x20 mm), which format of the cold-rolled steel sheets was used for the canvas - 1,5, 2, 3, 4 mm and the total thickness of the cloth according to GOST 19904-74. We will suggest that basalt plates are used for internal filling of the web, for thermo-tape sealing.

In addition, the door leaf should have a double-sided fire-protection screen with spraying. According to the norms and rules of the PB, the doors must open outward in the direction of the entrance, in some cases the fire doors may lead to another room. The doors of the boiler room's technical purpose are fitted with burglar-resistant handles and hinges.

ventilation of a gas boiler house in a private house

General requirements for ventilation of boiler houses are concentrated in the National Security Service 4.03.01-98.

The creation of the boiler room ventilation is also mandatory and involves communicating with the house ventilation system and supplying fresh air into the combustion chamber through the grate in the door. The normalized dimensions of the ventilation holes are:

- air flow outside 8 kW / 1 kW boiler power

- air flow from the inside of 30 sq. cm / 1 kW of power.

Let's say that the productivity of the ventilation plant of the boiler house on the gas should, according to the norms, provide a 3-fold inflow of air. It is known that the coefficient. increase in the frequency of air exchange depends on the ceiling height in the furnace room, and the fresh air supply rate is 1 m / s. By the way, the air exchange area helps to select and calculate documentation for gas equipment and units.

A significant criterion for creating a gas boiler house is the correct choice of the capacity of the equipment (boiler).

capacity of gas boiler, how to calculate

In order to select the required gas boiler among the numerous models, it is recommended to perform a preliminary calculation of its capacity based on the initial data - the total volume of the boiler room and the purpose (single- or double-circuit).

To determine the volume of the room S, multiply the room by h ceilings.

The capacity of the single-circuit equipment intended for installation is found from the table:

- room volume up to 30 m3, the recommended boiler output is 7.5 kW

- for a room volume of 30 to 60 m3, the boiler capacity is 13.5 kW

- for a room volume from 60 to 200 m3, a boiler with a capacity of 15.0 kW is selected.

In addition to the above requirements for the boiler house of a private house, it is recommended to provide efficient communications of the gas main, an uninterrupted power grid with reliable grounding.

Provision of boiler room communications

boiler house power supply

The parameters of the communications of the boiler-houses of gas are in accordance with the standards and regulations regulated by the operating services, therefore, "amateur performance" will have to be limited. Requirements for power supply and automation of the boiler providing emergency gas supply: single-phase current, Upt. 220V, I = 20 A will require the installation of an individual gas station and grounding.

tapping into the gas main

The requirements are recommended and it is supposed to place the boiler shut-off unit on the gas main by tapping under pressure into the existing low-pressure gas pipeline using the equal-run tee series 5.905-25-05 UG 23.00 with the transition to the required diameter.

All the useful tips for a gas boiler house private house are presented in the video.