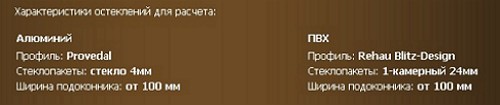

The glazing measures assume the exact calculation and installation of the frame structure. It does not matter what type of glazing is supposed to be used for them. The once patented invention of aluminum glazing acquired the scale of a total installation. And, in most cases, glazing is done by hand. The experience gained during the installation helps to carry out the glazing activities.

Content

Modern types of balcony glazing

Conditions of living in urban apartments and private homes dictate the use and use of modern practical materials. The glazing of balconies is produced using modern technologies, which provide for a specific improvement in design and creation of comfort. Complex projects, like panoramic glazing of balconies and loggias, need to be trusted by specialists.

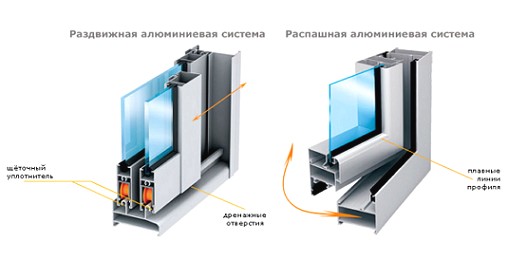

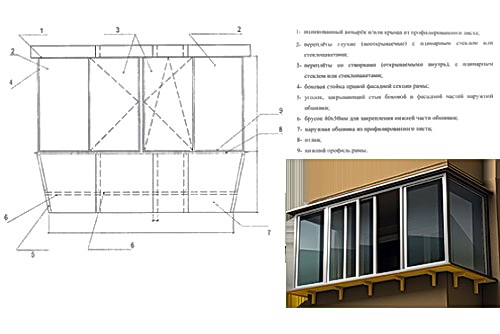

This is a warm and cold glass balcony or loggia. The system of cold glazing can be called an "economical" option, because the activities will be aimed at protecting the balcony from noise, rain and wind. For these purposes, use an aluminum profile, which do not have special inserts that reduce heat loss.

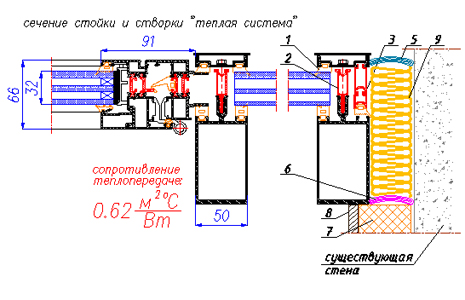

Warm glazing is produced using a plastic profile, the application of which increases the temperature inside the room. In addition, the plastic glazing of the balconies and the correct finish can expand the area of the room. For a warm type of glazing use multi-chamber profiles and wide double-glazed windows.

For example, the Gealan double-glazed window coefficient is the following configuration: 3K4Low-e / 12 / 4CF / 12 / 4Low-e, Ug = 0.6 Wm2K.

Naturally, the options for warm glazing are more expensive. Therefore, aluminum glazing of balconies is more in demand due to cost savings. Consider the options for cold glazing of the balcony.

Helpful Tips

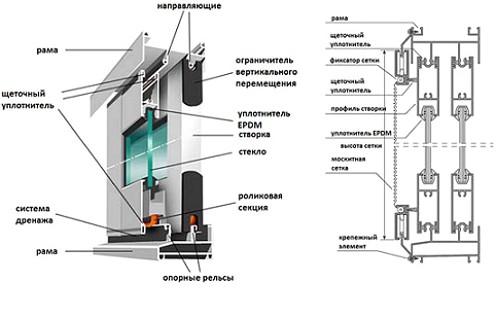

The most preferred systems of cold glazing can be safely called "Provedal" systems, characterized by a low price and the possibility of creating sliding glazing. Sliding doors at glazing gained their fans for their ability to save a small space of loggias and balconies.

Features of cold glazing

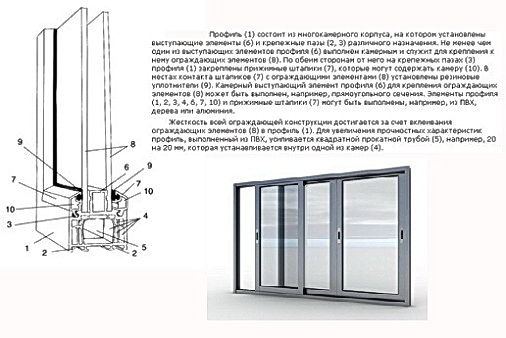

aluminum profile system

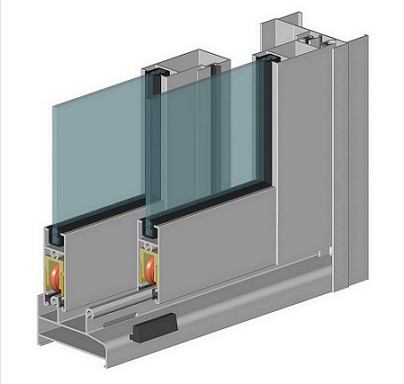

The production of the profile aluminum system for glazing is carried out by pressing from primary aluminum with subsequent coating by powder coating. The production technology provides the finished product with weather resistance and durability.

For example, with system of profiles ALT100, allows you to make loggias and balconies and create designs with different functional doors. The use of an aluminum profile is most important for panoramic balcony glazing.

The system of sliding constructions from aluminum can be called the first way of renovation and reconstruction of existing apartments and structures. The only thing to worry about is to insulate the floor on a balcony with cold glazing.

Glazing schemes for aluminum profiles

There are two schemes for glazing the balcony with an aluminum profile:

• glazing with removal of aluminum construction

• Creation of a structure without removal.

Any glazing scheme is implemented based on measurements and simple calculations.

Helpful Tips

When glazing rooms located on the last floors of high-rise buildings, there is a need for additional arrangement of the roof. To do this, build a powerful metal frame and lay the roofing material. In this situation, an additional calculation of the weight of the structure and the angle of the ramp is required. If you feel insecure about this issue - trust professionals, designers and accountants.

Calculation of the glazing of the balcony

The design of the aluminum structure is carried out according to measurements and preliminary calculations, which are made taking into account the type of the house, the material and the features of the walls or facades.

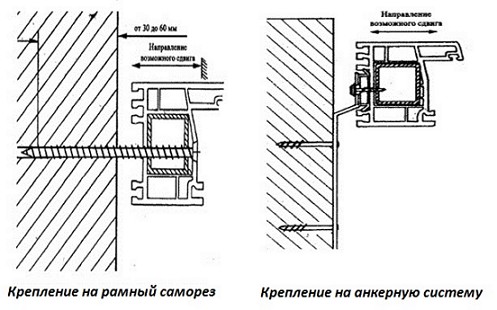

In the calculation, it is necessary to use such initial data: the length and height of the balcony opening. Naturally, it is recommended to choose the way of fixing the profile from aluminum.

Than to fix a profile at glazing?

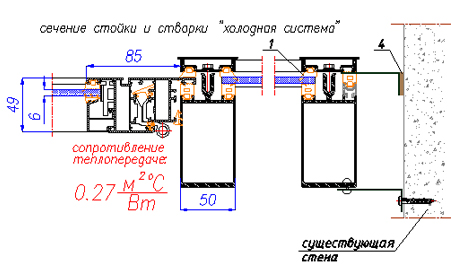

Variants of balcony glazing

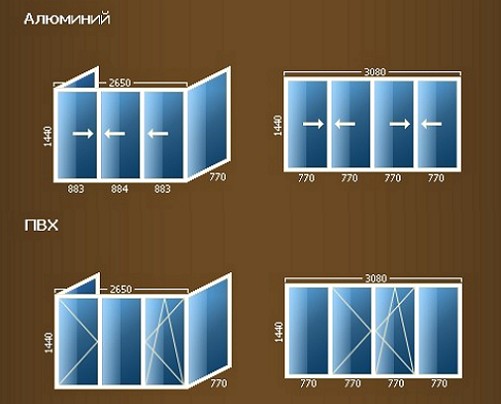

glazing scheme remote

Glazing with the removal of aluminum construction is a fence, located outside the balcony. The design is mounted on the outer brackets up to 40 cm in length, depending on the type of glazing chosen. To erect the top fasteners, a symmetrical belt of similarly sized brackets is prepared from above.

Then on the brackets reinforce the support bars to maintain the glazing body. The construction is fixed in such a way that the distance between the aluminum structure and the railings is blocked by the sill. Glazing with removal is structurally more difficult than glazing without an external structure. It is necessary to choose the brackets of the appropriate size, install them, and then make the installation of the aluminum structure.

The only advantage of this kind of glazing is the increase in the area of the balcony for the width of the beams of the installed brackets.

We make glazing by reading this video.

construction without removal

The glazing of the balcony is not remote, it assumes the fastening of the aluminum system directly to the fence. This design is more reliable, it is installed faster and easier.

How to make a cold glazing of a balcony without removal of a structure

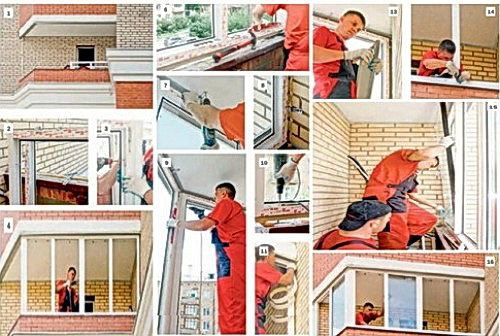

The main stages of cold glazing are:

• preparatory work, during which the dismantling of the old structure

• installation of a visor, apron and wooden blocks along the parapet

• installation of aluminum frame

• Low tide installation

• installation of window flaps in the frame

• Sealing of seams.

preparation of the balcony room

For installation of aluminum structures without removal it is necessary to remove old frames, if any. Balcony railings are cleaned from old paint, dust and debris with an iron brush or mesh. The existing holes in the old concrete fences are closed with cement mortar and shpaklyuem. Then the fixing of wooden blocks 50x50 mm on the railings and side walls. On the top of the balcony, the bars are installed in a similar way.

preparation of aluminum frames for installation

We disassemble the acquired aluminum constructions for glazing: it takes out the glass and all the mobile fastening elements. Mount the mounting plates on the frame. Mark the location of the plates on the frame in steps of up to 700 mm. Fastening of plates we carry out in fixing apertures by means of self-cutters with a drill for metal. We fix the position of the fastening plates.

installation of frame from aluminum on the beam

The frame of aluminum is located at the place of installation and vertically aligned. At the bottom and sides of the frame, the frame is fixed with wedges and pads. Then, the aligned frame is fixed to the support bar.

Fastening of the frame is carried out with the help of anchor bolts and plates. The frame is fastened to the anchor plates from above and below.

The mounting plate is bent to the attachment point, then through the mounting hole we drill a hole in the wall. In the formed landing socket we establish an anchor with a sleeve. After installing the frame and its vertical alignment, we form the assembly seam.

we form the assembly seam

Correctly formed assembly seam in the future will ensure a tight fit of the frame and thermal insulation. Therefore, the correct formation of the seam depends on how warm the glazing will be. To form the assembly seam use a two-component mounting foam, which is applied in two passes.

The first layer of the mounting foam is applied deep into the seam with partial moistening, which increases the effectiveness of the polymerization of the foam. Then the second pass is made in a few minutes, gently filling the seam, eliminating the outflow.

After the end of the installation, the frame and the flaps make installation of the tide and seal the joints.