At present, the building materials market is full of variety. Everyone will be able to find material for themselves not only of suitable quality, but also of acceptable cost. The fence can be made of corrugated board, combined, wooden. Skillful hands of the master will make a masterpiece from a simple material, specialists http://prigorodstroy.ru will be able to realize any of your whims. Great popularity is enjoyed by corrugated board.

Content

Profiled, what kind of building material

Profiled sheeting or profiled sheet is a sheet of cold rolled steel coated with a protective layer of polymers, zinc or an alloy of aluminum and zinc. During the manufacturing process, the smooth sheet acquires a ribbed shape passing through the machine tools. This gives it more strength and stiffness. Its strength depends directly on the height of the rib.

The dimensions of conventional sheets are:

- width 1130 - 1200 mm;

- length 300 - 12000 mm;

- thickness 0,4 - 1,2 mm.

This material can be divided into three types:

- The wall is widely used for making fences and wall cladding. The height of the rib can vary from 8 to 20 mm.

- Roofing is used for the construction of roofs and ceilings. The height of the ribs is 44 mm. On its surface there are special gutters for water drainage.

- Bearing is used for formwork in monolithic construction. This is the most durable type capable of withstanding heavy loads. The height of the rib is 57 mm.

In addition to all the above, corrugated board has a number of advantages over other materials.

Namely:

- light weight, which has a favorable effect on transportation;

- strength;

- attractive appearance;

- ease of installation;

- excellent tightness;

- a long service life of 30 to 45 years;

- possibility of reuse.

The most important thing is to choose a material with a galvanized coating. He is not afraid of atmospheric precipitation and corrosion. Such material can be used to construct a fence and a roof.

Choose the corrugated board for the fence

In the private sector of cities and in cottage settlements, you can often see fences made from corrugated board. They are beautiful and easy to install. What kind of material to choose for such purposes. Here it is necessary to consider not only the price side of the issue, but also the aesthetic component. Let's talk about this in more detail.

profiled sheeting

An important issue is the price of the material and the total cost of the fence. Since the fence is not required for increased tightness and withstand high loads, it is possible to take a profile with small ribs and a thickness of up to 0.7 mm. Most often for these purposes apply wall profiled sheets. At a small thickness, the material has good sound insulation properties, and will also prevent the penetration of dust and wind onto the site. The fence will look presentable and elegant. It is also necessary to clarify the life of a particular material, since it is protected by an anti-corrosion coating. The most budgetary version is made of galvanized steel, and its service life is 10 - 15 years. This option is cheap, but not practical. It is best to give preference to sheets with a polymer coating, which performs more decorative functions. And the coating can be both from one and two sides of the material. Such a fence will look great in the general plan of buildings and will last much longer, up to 45 years. Another important nuance is the appearance of the material. After all the fence should be also beautiful. Now many manufacturers apply on profiled sheets of the image with the help of offset printing. Thus, it can perfectly imitate the pattern of a tree, brick or masonry. If you want, you can order sheets with a picture of flowering plants or your favorite scenery.

Summarizing all of the above, we can briefly formulate the main nuances:

- pay attention to the quality and thickness of the sheet, enough for sampling 0.5 - 0.7 mm;

- make sure that the goods are certified and produced with the established specifications;

- for a fence, you can choose a wall profile, it has not only an affordable price, but also a large useful area;

- do not save on money, it's better to choose a durable material in the price segment that satisfies you;

- look through the catalog of colors and textures before you decide on a particular type.

Calculation of the fence from the corrugated board

When building a fence, you need to know how much material is needed. For this, it must be calculated.

This can be done in two ways:

- online calculator;

- manually.

In the first case, everything is quite simple. We go to the manufacturer's website or just type in a query about similar calculators in the search engine. From you need to enter several parameters in the form fields and press the button to calculate. After that you will see how many sheets you need.

The second option is different in that all the calculations you do yourself. To begin with it will be necessary to be defined with a mark, after all each of them differs on the size. Let us give an example of calculation. The fence is mounted from corrugated board S-21. It is planned to spend 3 sheets per run, the useful width of each 1000 mm. The width of the pillars is 100 mm. Thus, we find the width of the run: 1000 * 3-200 = 2800 mm. Suppose the perimeter of the plot is 60 m, so the number of sheets is calculated as follows: (60 (perimeter) - 20 (number of columns) * 0.1 (width of the column)) / (2.9 (distance between poles)) * 3 (number of sheets in the run) So we get 60 sheets. Which way is more convenient for you to decide, we only considered the most obvious options.

Construction of a fence of corrugated board

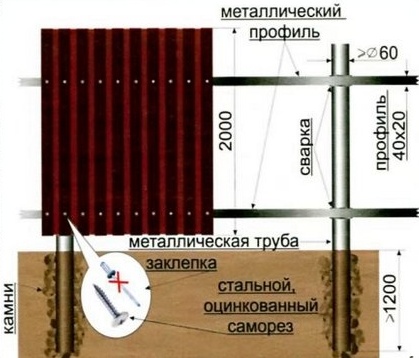

Like any construction work, the fence installation takes place in several stages. Excavation. With the help of a shovel or a garden borer, we make grooves under the pillars. It is necessary to start from the gate.

- Preparation of cement slurry.

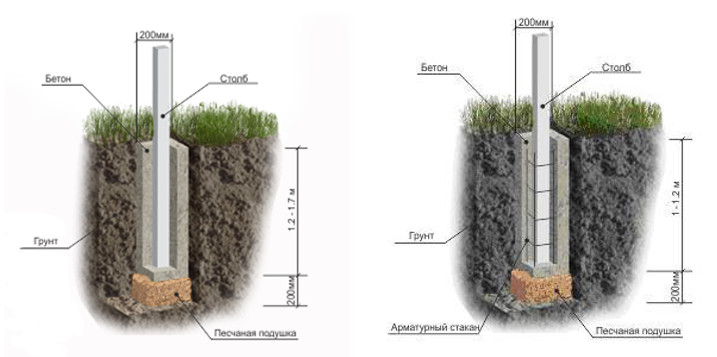

- We set the posts in the pits strictly vertically, after which we pour the solution. After that, with the help of improvised means, we take a solution for air release.

- After the solution has risen, lags can be installed. This is possible with the help of welding, a simple and reliable type of fastening is enough. But not everyone can do it themselves. You can use the connection with bolts. To do this, drill through holes in the lags and racks. After that, the elements are connected by means of a bolt and a nut. And lags should be installed at a distance of 20 cm from the ground and the top of the column.

- Fastening sheets of corrugated board. It is necessary to start from the gate. Each sheet is set according to the level, after which it is fixed with three screws (two at the edges, one in the middle). The next sheet is overlapped by the previous one by one wave.

As a result, a reliable and beautiful fence will be obtained.

Poles for fence from corrugated board

The fence consists of several elements:

- bearing structures;

- crate.

The first are the pillars and the slogans attached to them, the frames. The cladding can be made of different materials, be it wood, metal or mesh. The reliability and durability of the entire fence depend on the quality and material of the pillars.

metal fence posts

They are considered the most reliable. For them, you can take the metal pipes and install from a certain step, fixing the cement mortar. This species has a disadvantage, namely the effect of water. It can get inside and in winter, when frozen, it can damage their integrity. Therefore, it is recommended that the metal pillar be filled with concrete and covered with special caps.

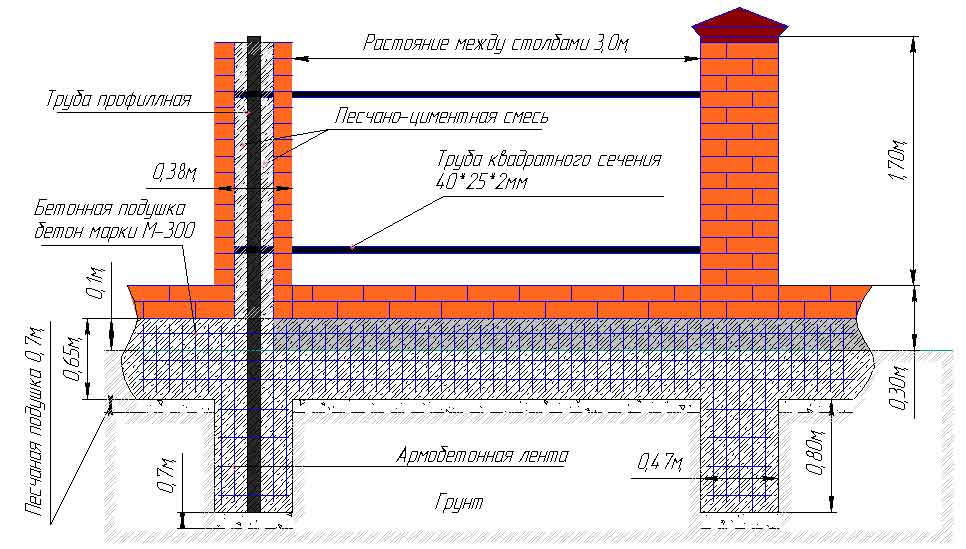

fence posts made of bricks

This type of pillars looks beautiful, especially if the brick for the pillars is selected in that to the lining of the house. For the manufacture of such pillars, it is necessary to make a foundation, and then map out the places where the bricks are laid. To impart strength to the pouring of the foundation, you can put metal poles. After the solution has risen around them and lay out the pillar. They will serve as additional rigidity for the entire structure. Such poles can be covered with caps in tone to the fence. This will create a holistic picture and a neat appearance of the fence.

Fence installation from corrugated board price

Before you start work on the construction of the fence you need to find out the prices for materials. So profnatil is in the range of 420 - 698 rubles per sheet. Also, lags are required whose cost starts from 240 rubles per 3 m product. In addition, without a support, you will not get a reliable design, so you need poles. Their price varies from 420 to 1500 rubles apiece. In addition, self-tapping screws and bolts are required. If you are planning to order work in specialized companies, then it will cost you from 500 to 700 rubles per running meter. Based on the cost of materials, you can adjust the estimate for the upcoming work.

This article describes the profiled sheeting and its characteristics. The cost of the material, as well as the criteria for selecting the models for the fence, are given. Using the information of the article, you can choose the necessary material and build a fence on the site yourself. Successful work.