Returning from the roof to the area of architecture, we can say that the additional strips represent a combination of elements playing the leading role of the border and the space that is enclosed between them. "Tin!", - the reader will say. That's right, tin, but what!

The strict geometric shape of this coating is a reliable barrier to moisture and wind. But to choose and strengthen the bar is necessary by the rules.

Content

Two faithful friends - a cornice and an end plate

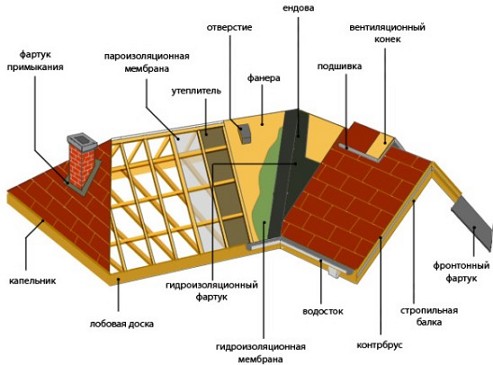

An integral part of a well-mounted roof are additional elements - the cornice and end plates. Reliable protection of the roof covering with other elements of the roofing system: dormer windows, drainage system, ventilation ducts and chimney using the laths is guaranteed.

Each curtain rod performs its specific function. The curtain rod protects the frontal board from possible wetting, and the end strip protects the roof covering and crate from the wind. Structurally, the strips are similar to each other, because the manufacturers make them using identical technology with basic sheets of metal or profiled sheets.

The basis of the strips is galvanized passivated steel up to 0.5 mm thick. The wind bar is made with a polyester and plastic coating. Composite end strips are additionally coated with basalt chips. What are the differences between fixing the windshields for different materials?

End plate fastening technology

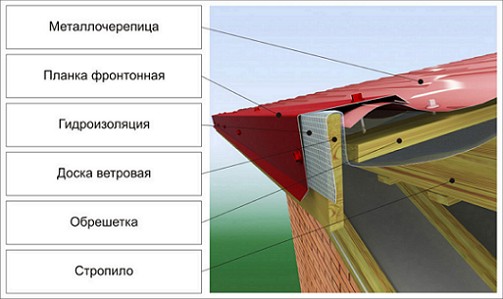

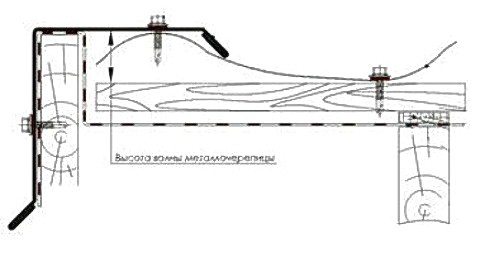

Fastening of the end plate for metal and corrugated board are slightly different and depend on the relief of the material. Profiles sheet profiled and metal are similar, so it is technologically justified to fasten them to the highest ridge.

The wavy profile of the metal tile and the corrugated board, as well as the rigidity of the materials, presuppose the use and application of special bending devices. Planking and sheets of roofing material are lapped.

adaptations for work

When forming the edge joints for the installation of windshields, scissors for metal and the tinsmith's clamp are used. Scissors for metal are manufactured by the manufacturer of chrome-molybdenum steel. Scissor arms are equipped with protective arms for hands and a crochet for closing the cutting edges.

The tinsmith's clamp is used to mechanically change the integrity of the surface when changing the profile of the metal tile. A special locking clamping mechanism allows simple and precise bending. Fixation is carried out by simply pressing the handles. Adjusting the clamping force is possible with an adjusting screw.

Armed with the device for work, we proceed to install the end plate.

We fix the bar on the metal

The wind bar on the metal roof is installed after the final installation of the shingles. The task of the bar is to cover the ends of the roof tiles formed after laying the wind and moisture.

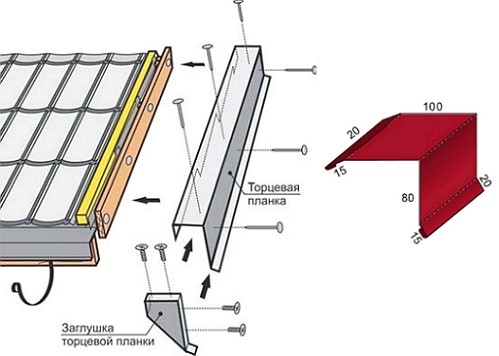

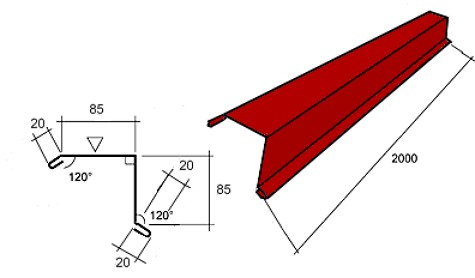

The dimensions of the end plates are up to two meters in length, the width of the shelves of the slats can be from 130 to 145 mm. The bar is mounted in stages:

• installation of the bar above the level of the roofing

• Layout of the strip with respect to the angle of the end face

• fixing the position of the overlap and the joint of the lath from above and from the side.

For some types of metal tiles, it is necessary to distinguish the left-hand and right-hand sides. Therefore, right and left wind bars can be used in the pediment nodule.

The fronton bars are designed for finishing the right and left gables. Mounting the gable planks begin from the bottom upwards with an overlap of at least 10 cm.

The rigidity of the construction of the bar and sheets of shingles assumes the use of seals for installation. The fixing point is the maximum of the tile wave, and the junction point is the center of the end plate.

The fixing element for the mounting of the bar is self-tapping screws, which are installed in steps of 20-30 cm. If the roofing sheet of metal roofing is laid correctly, the bar must cover the end over the profile wave.

Make the correct mounting of the wind bar will help this video.

How to fasten the wind bar to the corrugated board

Correctly equipped gable roof section from corrugated board will exclude the cutting of sheets. Mount the end plate after laying the main sheets. How to choose and how to fix the end bar?

Plank end for corrugated board is a component of the roof. The purpose of installing the bar is to increase the area of the lined surface. Plank is a flat bent sheet of profiled material. The end plate has an end-cap.

To ensure that the roofing connection has the necessary rigidity, the sheets are installed on the end surface. For this purpose, an additional grating is also arranged.

Stages of installation of a lath:

• the bar is installed perpendicular to the end of the roof

• We make the mounting of the strip to the end part by means of screws or rivets

• install the plug with self-tapping screws

• we process the joints with a mastic sealant.

If the allowance for the front of the roof is small, then you should choose the bar with the dimensions of the shelves 25x80 mm. Recall that the end plate resembles a steel corner. The recommended step of fixing the bar is 200-300 mm, the overlap can be 100-150 mm.

Installation begins at the end of the roof. Mount the bar after the first wave of corrugated board with a lateral overlap of up to 50 mm. For a shallow slope with a slight inclination angle, the overlap may be up to one and a half wavelengths. For longitudinal and lateral joints, a seal is provided with the use of a sealing tape and bitumen mastic.

Helpful Tips

Experts do not recommend using on one plane of the roof several laths connected together. Any improper fixing reduces the resistance of the roof to wind loads. Therefore, the ratio of the roof to the external environment is preferable to make correctly. And then the roof will last longer.