Iron garage is not only a parking lot, but also a place for storing tools and building materials. If a person begins to build a house from scratch, he faces the problem of storing an expensive tool and building materials. In this case, it is relatively cheap and quickly possible to solve the problem by installing a metal garage. In accordance with the need, the landlord can create his own construction and build a garage of the right size. Garage can be capital, prefabricated or collapsible, a garage with a viewing pit, you can create a mobile garage on skids, etc.

Content

Metal garage, how to simplify the construction of a metal garage

In the simplest way, you can suggest buying a prefabricated or collapsible metal garage.

You will acquire workpieces and having little skills, with an assistant, collect the garage within one week.

The advantage is that the garage will be very economical and fast in the assembly.

In addition, the garage will be lightweight, and as you know, a lightweight structure does not require a solid foundation.

But, if you need a more reliable structure, or you can not find the right size garage, you can build a garage of your own design.

To simplify the construction, create a drawing of the future design and order the cutting of metal sheets, the right size, from a specialized firm http://www.neolaser.ru/service .

Modern firms are equipped with special laser equipment that can cut metal of any thickness.

Having received the garage garage, having acquired the necessary tools and basic materials, it is possible to start construction.

Metal garage, materials and tools for building a garage with their own hands

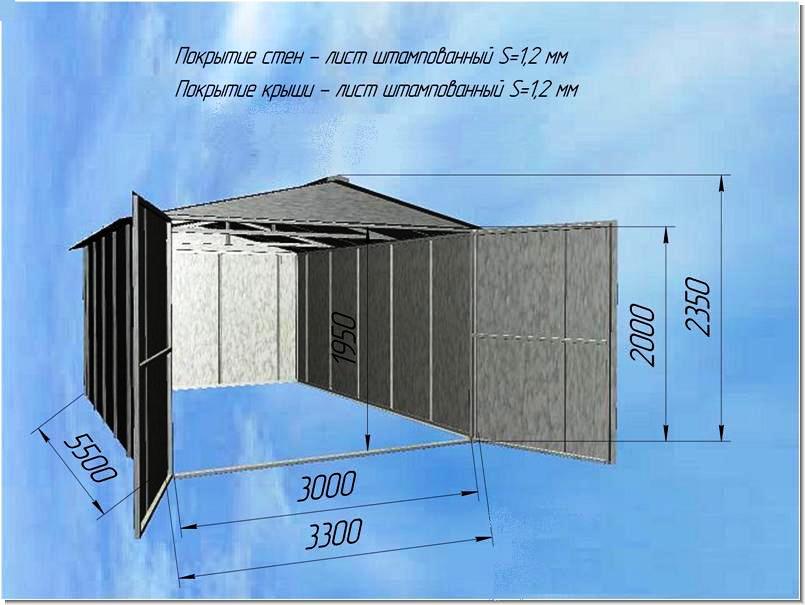

If you decide to build a garage of metal completely with your own hands, make a drawing and specify all dimensions on it.

If the garage is built to store the tool and the building material, the dimensions of the garage must correspond to the maximum size of the building material.

If your garage is designed to store a car, the width of the garage must be at least the width of the machine with the doors open, plus 20% of this total width of the car.

The length of the garage should be no less than the length of the machine plus 20% of this total length.

If you intend to repair the car in the garage, add to the dimensions of the garage the dimensions of the bench, the dimensions of the shelves for storing the instrument, etc.

The dimensions of your garage should allow you to move freely and work comfortably.

Having defined the dimensions and drawing a drawing of an iron garage, prepare the necessary tools and materials:

- for the foundation it is necessary to purchase reinforcement and concrete, if possible - purchase ready-made concrete blocks. Ready-made concrete blocks will facilitate the work and reduce the time for the foundation;

-if you want to make an iron garage mobile, purchase a metal pipe with a diameter of 10-15 cm, from it you will make skids;

-metallic corner is best to pick up a size of 50 mm, from it you will make the frame of the future garage;

-The walls of the garage made of metal are quite suitable for a thickness of 2-2.5 mm. In accordance with the size of the future garage, purchase the corresponding sheet metal;

- a grinder with cutting and grinding wheels - a necessary assistant;

- Welding machine and electrodes - the necessary equipment for creating the desired design;

-For future gates, purchase hinges, locks and bolts;

-if the floor is supposed to be wooden, purchase boards for flooring in the right amount;

- Prepare the primer and paint to work in the final stage.

Metal garage, foundation preparation

If the garage is built mobile, on metal skids - in this case, the foundation is not required, but it is necessary to remove the fertile layer of the earth.

Removing the fertile layer of the earth will exclude the rotting of the organic material under the bottom of the mobile garage.

If the garage of metal is supposed to be built stationary - such a garage requires a capital foundation.

Before laying the foundation, it is necessary to remove the fertile soil layer to a depth of 40 cm. The liberated area is covered with coarse-grained sand.

Sand will allow to remove water from the basement and exclude the frost heaving of the soil directly under the garage.

With the help of stakes and twine, the basement under the garage is marked out. A trench is perforated along the perimeter and a formwork made of boards is built, the formwork above the ground should rise to 30 cm.

The bottom of the formwork is laid waterproofing in the form of a polyethylene film or roofing material.

Bricks or stones are placed on the bottom and using two rows of reinforcement 8-10 mm. an reinforcing mesh is made, while the reinforcement is connected by wire and a three-dimensional construction is created.

In the corners, anchors are made of reinforcement 16 mm, the anchors protrude above the ground to a height of 30 cm.

In the future, the garage frame will be welded to these anchors. A concrete mixer is prepared in a concrete mixer or a metal trough.

To do this, take cement (M500), sand and gravel in a ratio of 1: 2: 2. The formwork is filled with concrete completely, the top layer is leveled and the foundation is left to solidify.

Concrete matures completely after 28 days.

Metal garage, cook carcass of garage

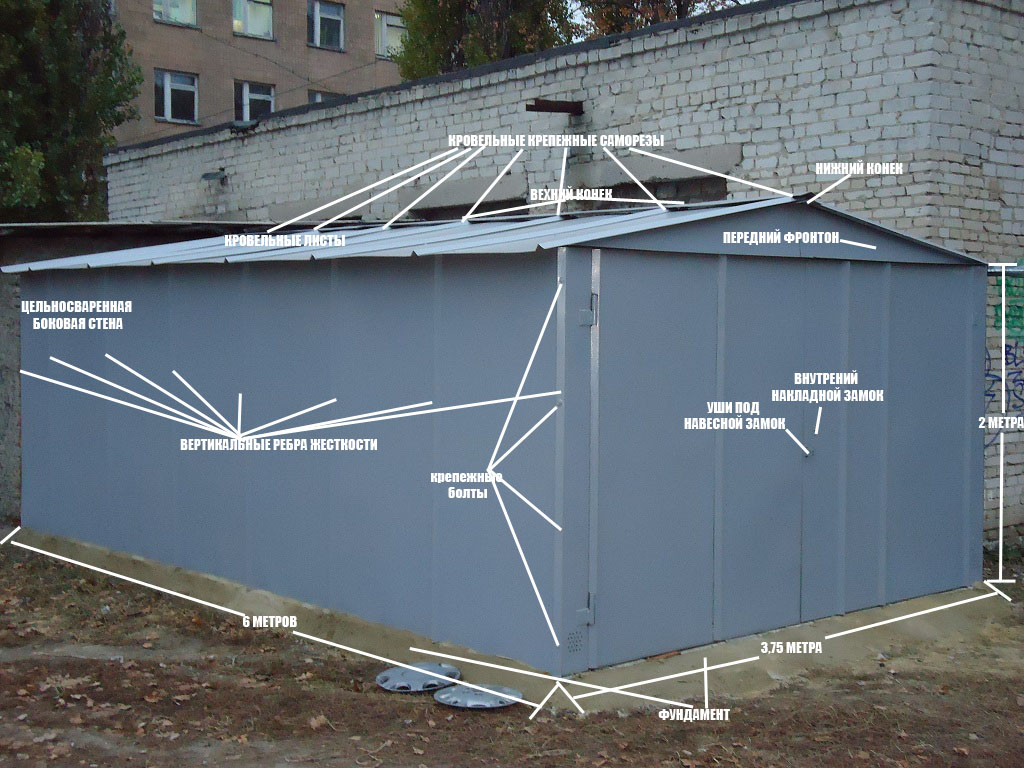

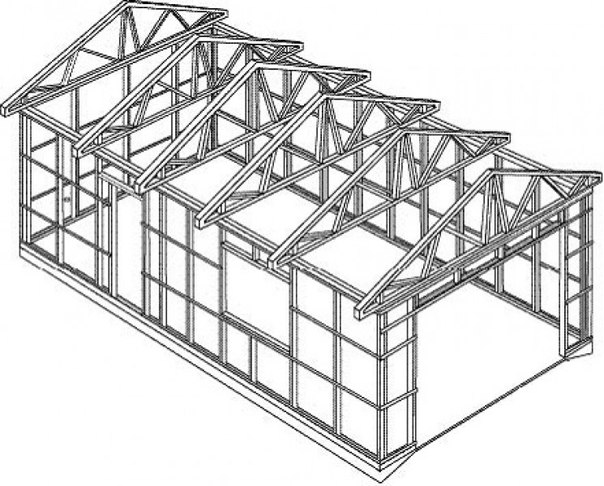

After the concrete has grasped, the skeleton is started, which consists of a metal corner.

The first task for builders is to install a lower frame along the entire perimeter of the basement.

The frame is welded by spot welding to the anchors, during operation it is necessary to monitor the correspondence of right angles.

After the lower frame is ready, at the corners, the columns from the corner are strictly vertical, in accordance with the dimensions of the iron garage.

The posts are welded with an acute angle to the outside.

Welding is done to the lower frame and to the anchors.

After all four corner posts are installed, if the dimensions of the future garage are large, additional racks are installed at a meter distance from each other.

At work special attention is paid to geometry, observance of a right angle and parallelism.

After performing the above work, the upper frame is welded.

The upper frame is a support for the ceiling and roof.

To create strength, reinforcement ribs are created from the reinforcement.

The armature is welded diagonally to the walls with a cross to the cross.

After the box is ready, the skeleton of the gable roof is made.

The rafters are welded to the positions of the racks, the roof ridge is made from the corner as well.

Metal garage, garage wall lining

If the garage frame can be made on not completely ripened concrete, then the garage lining, with metal sheets, is done only after the concrete has matured.

If the concrete does not ripen, a heavy structure can ruin the foundation.

And the metal sheets give the garage considerable weight.

With the help of the Bulgarian, the metal is cut according to the size of the walls and roof.

The open sheets are initially welded by spot welding. After all the sheets are fixed with spot welding, the seams are fully welded.

Metal garage, we make garage gates

In accordance with the drawings, the frame of the garage door is made from the corner.

To make the stiffness, diagonally, weld the reinforcement.

If there is a possibility of deflecting the gate - strengthen the frame with wooden blocks.

With the help of welding, attach the hinges to the gate and to the garage, plant the frame of the gate on the hinges.

After the frame is installed, on the outer side, coat the frame with metal.

If desired, you can warm the garage with foam or polystyrene. Heat insulation can be plastered and painted.

It remains only to paint the garage.

Before painting, the metal is cleaned from rust, primed and painted with paint for metal structures.