Pragmatic lifestyle and living in private homes allow maximum use of the possibilities of innovative technologies of building materials. Warm and protect the under-roof space and attic can be with the use of vapor barrier films, creating with their own hands a balanced microclimate system.

Content

The moisture should be where it needs to be

The regulated rules for installing a vapor barrier are defined in SNiP 11-3-79. Building heat engineering. According to the current building codes and regulations, the vapor barrier device "is provided for pitched and flat roofs and ceilings using bulk or fibrous heaters."

An important task of vapor barrier and waterproofing materials is to ensure the operating mode of thermal insulation. Thanks to the vapor barrier film, the insulation is extended for a long time. Parobarrier arranged on the inside of the roof or overlap.

Being part of a well-balanced part of the roof and ceiling ventilation system, the film actively participates to prevent the accumulation of moisture vapor and the formation of condensation.

The qualitative and professional laying of the film on the roof is given special significance. The execution of the abutment of the film to the elements of the roof and the sizing of the joints must be performed flawlessly. How to choose and lay the vapor barrier film?

Purpose and technical parameters of the vapor barrier film

The main purpose of the vapor barrier film can be safely called:

• the ability of the film, regardless of the material and nature of the forces displacing the support base, elastically accompany the displacement without damaging the integrity

• being on the support, keep plasticity without additional protection during possible mechanical damage.

When assessing the quality of vapor barrier properties, there are certain characteristics. These are the indicators:

• water vapor permeability or ability to pass water vapor through a certain time interval of 1 sq.m.

• coefficient of diffusion thickness of water vapor (Sd)

• coefficient of resistance to the water column.

In the manufacture of a vapor barrier film and membranes, the industrial process uses modified bitumen and polymers. Films and membranes of polymer of plastomeric type (atactic polypropylene APP) and polymer of elastomeric type (styrene-butadiene-styrene SBS) were most widely used.

How to choose a vapor barrier film for roofing

Choosing a vapor barrier film, intended for laying on the roof, you need to focus on such indicators:

• The main characteristic of the film vapor barrier, showing the amount of moisture that the film will be able to pass (from 0 to 30 g / m2 per day

• Film strength and ease of installation

• Resistance to UV radiation.

It should be remembered that a strong film for vapor barrier insulation should not lose its integrity from accidental mechanical action - the fall of a tool on it. An important indicator is the resistance to sunlight. At low resistance to UV, the film practically loses its performance. During installation, this film should be covered with finishing materials as quickly as possible.

For example, vapor barrier film yutafol has such industrial characteristics:

• density of 96-110 g / m2

• thickness from 0,17 to 0,22 mm

• vapor permeability & lt; 1 g / m2 / day (at t + 23 ° C and humidity 85%)

• diffusion thickness (Sd) 36-40 m

• strength for mechanical fracture - 210/190 N / 5cm

• stability to UV - 3 months.

Let's tell, that leading manufacturers of a film for a steam insulation of a roof consider:

• JUTA vapor barrier films and membranes

• vapor barrier film SpanBel

• Climbing membrane Climateq.

The vapor-permeability properties of the film are indicated by the presence on the material of the marking (strip), which indicates the size of the bookmark for the overlap.

In addition, the film can be combined with insulation from Paroc basalt, Isover glass fiber and polystyrene group materials.

The whole secret of the "friendly interface" and the exceptional properties of the vapor barrier is contained in its multilayer structure.

To the barrier!

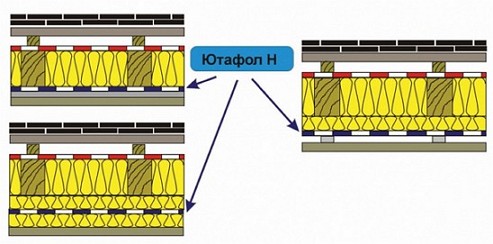

The nomenclature of the vapor barrier Yutafol is designed for the construction of a roofing multilayer pie, as well as flat pitched roofs. The Unifol and Yutafol vapor barrier film is produced by embossing from polyethylene (HDPE) with a thickness of 0.8-2.0 mm, a length of 100-250 m and a width of 5 m.

The film consists of several layers of a propylene film and a reinforcing mesh carrier. Reinforcing mesh creates the necessary strength and elasticity, reinforced with double-sided lamination.

The vapor barrier barrier creates a reflective layer of ultra-thin aluminum film.

For example, the vapor barrier "Jutafol Silver", containing aluminum pigments, should not be contacted with a heater. In this case, the film is fixed on the rafter system or lags.

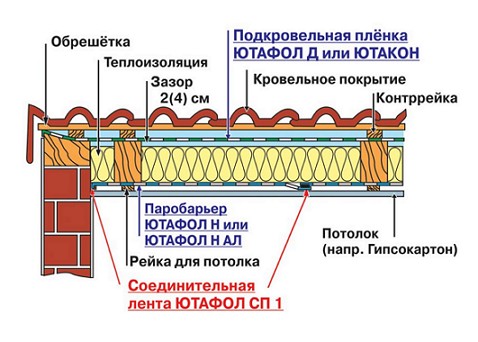

Recall that the total thickness of the insulation from the premises under the layer of vapor barrier should be minimal in comparison with the thickness of the insulation from the outside. This means that the vapor barrier of the ceiling must be made technologically correctly.

How to install a vapor barrier

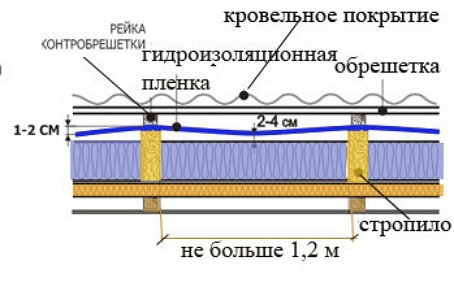

The technology of laying the vapor barrier film is identical for most types of roofing insulation.

For example vapor barrier film tell you about the technology of styling.

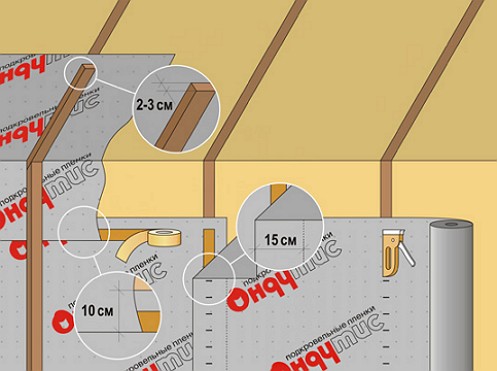

The film is cut and prepared for the dimensions of the working surface. To the crate the film is fastened using a construction stapler. The film is placed from the inside of the insulated insulation with a smooth surface upwards or towards the room.

The film has horizontal or vertical stripes with an overlap, the width of which is declared by the manufacturer.

It is preferable to fasten the film to the wooden frame elements, struts or flooring. For fixing the film, use clamps.

Then the joints of the film are glued and sealed. Depending on the material of the roofing, the top-mounted vapor barrier is fixed with 3x5 cm rails.

After the installation of the parobarrier, you can start laying the decorative roofing.

How to lay a vapor barrier film with an aluminum layer is shown in the video.