The intention to create a filler floor should be based on the success of using dry mixes from the manufacturer. The composition of each filling mixture is carefully calculated and tested by the manufacturer for reasons of ease of preparation and application of the solution. The usefulness of the activities will be justified if you have a clear idea of the characteristics of the mixture of the bulk floor.

Content

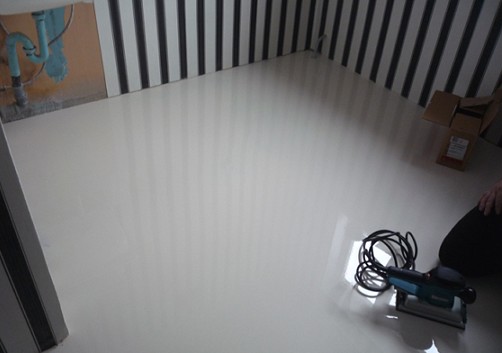

Filling floor

The need to create a bulk floor in residential or administrative premises determines the choice of type of coverage. The accumulated experience of specialists helps to systematize knowledge and skills on pouring sex. The choice of the floor type - gypsum or cement flooring - dictates the pouring technology and the use of leveling mixtures for the floor. A source information can be found at ekopol.kz.

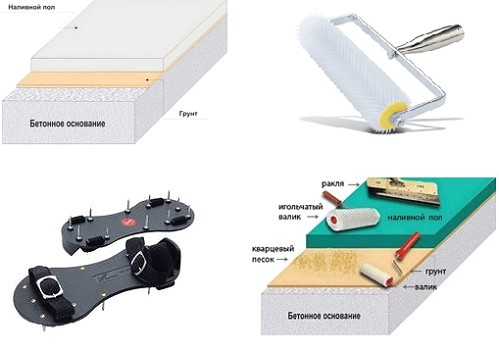

The enlarged technology of self-leveling floors involves the preparation of the working base and the actual process of pouring the prepared solution of the self-leveling mixture.

Naturally, it is necessary to study the characteristics of any kind of sex and its characteristics. For your information, the process of creating a self-leveling floor is a time-consuming process that takes several days.

Types of bulk floor

There are the following types of flooring, the technology of which determines the characteristics of the fill:

- mixture based on gypsum and cement

- the mixture is based on a polymer binder.

The choice of the type of mixture for the floor determines the humidity of the room and the thickness of the leveling layer. Technological regulations for the creation of a bulk floor assumes a minimum layer thickness of 3.5 mm. Dry mixes from the manufacturer, such as the fast-hardening floor filler, will form the final leveling, have a significant material consumption when pouring.

To reduce the cost of measures in the creation of a leveling layer, the use of cement-sand screeds is practiced.

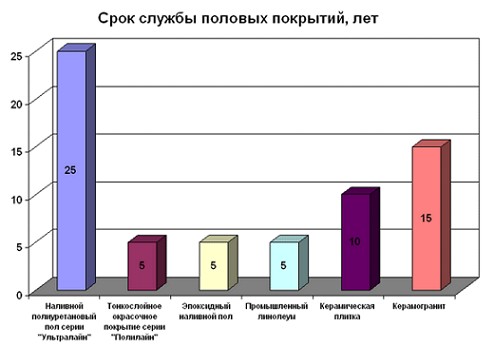

However, the use of a self-leveling floor as a self-leveling floor will be justified if it is not possible to meet the requirements of the final coating of a concrete screed. The composition of polymeric bulk floors depends on the type of polymer used: polyurethane, epoxy or cement-acrylic.

characteristics of gypsum floor

Gypsum flooring is designed to level the concrete surface and provides the basis for finishing.

Thin layer gypsum mixture is recommended for use with a 30 mm thick floor device.

However, the cheapness of technological measures and the quickness of applying the fill with one's own hand and drying out the layer to a marketable kind does not yet mean a complete victory over cracks and potholes.

As a leveling or intermediate layer, a factory preparation solution with an astringent calcium sulfate component can be used.

The gypsum filler floor is quite fragile and completely incompatible with adhesives for cement based tiles. This means that creating a finish in the form of a tile will be problematic.

How to fill the filler floor self-leveling plaster is shown in this video.

Looking at the video, we can conclude that the main tools and consumables for creating the coating are: a needle roller and a rule, not counting the buckets with the finished casting mixture.

Helpful Tips

The creation of a filler floor is based on the conditions of its subsequent operation and of course the cost of the mixture. For example, gypsum self-leveling screed Knauf and Knauf finely divided filler for smoothing the unevenness of the floor can be safely used in dry rooms. To create a layer with a thickness of 10 -15 mm, the consumption of the mixture is 19-21 kg / m2. For residential premises with low humidity, a gypsum floor device is recommended, otherwise it is better to give the cement floor a preference.

characteristics of a self-leveling floor on a cement basis

The filler cement floor is a thin layer (up to 40 mm) leveling mixture.

The characteristics of the cement floor are:

- the flexural strength is 5-7 N / mm2 and the compression is 25-30 N / mm2

- strength of adhesion to concrete surface (up to 7 days)

- the thickness of the layer is 10-35 mm and the material consumption is 18 kg / cm2

- abrasion and moisture resistance.

Filling technology consists of a preparatory stage (cleaning and priming of the surface), preparation of the working solution, pouring the mixture, which is produced by beacons.

The life cycle of the finished solution is 40 minutes, so the dry mixture is divided into portions and the filling is gradually produced.

Self-leveling floor, step by step instructions

The main stages of creating a bulk floor are:

- preparatory stage, including cleaning and removal of visible defects on the working base

- machine surface grinding followed by a primer

- preparation of working solution of bulk floor

- application of the base layer from the working solution of the mixture

- finishing coat application.

step by step instruction for the concrete surface

On the surface of the base, we remove the roughness and swelling, crack any degree of opening and potholes with a mortar. For surface grinding we use grinding machines.

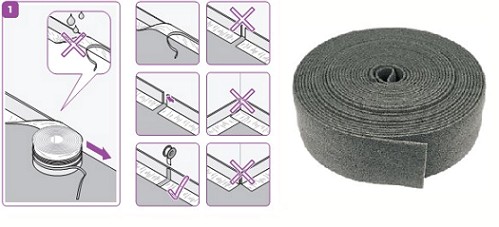

Then we beat off a horizontal line marking the level of the floor and place along the perimeter a damping tape with a width corresponding to the thickness of the filling layer.

We make priming for 2 -3 times a primer of deep penetration.

We apply a primer layer from the finished material to close the pores in the concrete surface using a roller. The primer should dry for 8-12 hours according to the manufacturer's recommendations.

After finishing and readiness of the primer layer for subsequent operation, we apply the base layer from the prepared mixture. The base layer is considered to be a continuous layer without the presence of visible defects.

Preparation of the working solution is carried out according to the instructions to the composition of the mixture. The solution is stirred twice and allowed to mature for 5 minutes.

Cement filling is prepared before the direct installation of beacons.

The correctness of the installation of beacons is checked with the use of a laser or a tonic level with strict observance of the horizontality.

The next step is pouring the finished solution.

The base mixture (leveling solution) ideally should have ductility, fluidity and adhesion to the substrate.

Gypsum, cement or polymer composition is poured from the container onto the floor surface by the method of filling, with simultaneous distribution over the entire area of the coating. When applied, the mass should spread over the surface of the floor with a thin layer. The distribution of the mass and the removal of air bubbles are carried out using a needle roller of a width of 30-40 cm.

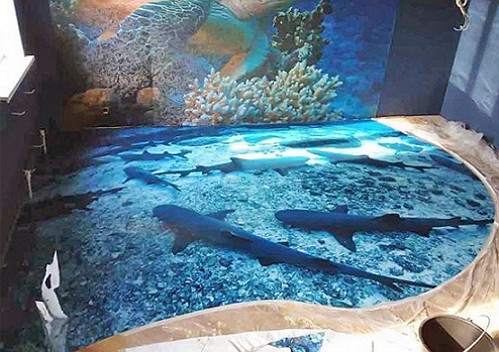

All the useful tips on how to fill a mixture with a polymer-binding component are presented here.