Depending on how actively the sewerage system is used, how many people live permanently in the house, as well as the financial possibilities, give preference to one or another type of cesspool. There are several types of cesspools, differing in the type of construction used by the building materials and the principle of operation.

Content

- 1 Types of cesspools

- 2 Calculation of the discharge pit

- 3 Pit of concrete rings with your hands

- 3.1 concrete rings for drainage pit, sizes of concrete rings

- 3.2 choose concrete rings

- 3.3 cesspit materials

- 3.4 digging pit for a drain pit

- 3.5 installation options for concrete rings

- 3.6 whether it is possible to lower the rings manually without a tap

- 3.7 pipe laying, concreting, ventilation installation

- 4 Helpful Tips

Types of cesspools

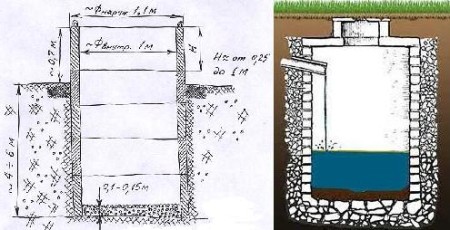

There are cesspools open and closed. Open pit cesspits are only relevant when the total volume of sewage does not exceed one cubic meter per day. The open pit cesspit does not have an artificial bottom, so some of the liquid will go to the ground.

Of the advantages of open-pit cesspools, one should note the savings, since silt on the bottom accumulates very slowly, and the need to pump the pit rarely occurs. Out of the minuses, an open pit cesspit pollutes the environment. This is especially dangerous if there is a source of drinking water nearby, for example, a well.

The closed cesspool is a completely hermetic structure. The bottom of such a pit is watertight, so the sewage does not pollute the environment.

A closed cesspool is a good option for a small suburban area, whose inhabitants use a well or a shallow sand well as a source of water.

From the shortcomings - a constant need to monitor the level of sewage in the pit and periodically cause the sewers, which entails financial costs.

In the construction of cesspools, a wide variety of materials can be used - this can be a simple plastic reservoir. Sometimes, if the volume of sewage is very small, a usual plastic or metal barrel can be used as a reservoir for the pit.

Quite popular are designs made of ordinary building bricks, especially if the pit is large. These are practical and inexpensive designs that can withstand the pressure of the ground well, besides, the brick is not afraid of moisture and is not easily affected by chemicals.

One of the most practical, reliable and durable options is a cesspool with concrete walls. These are durable, unpretentious in maintenance designs, resistant to the influence of an aggressive chemical environment. The concrete cesspool can be cast or assembled from pre-fabricated concrete rings.

The drainage pits can also work in different ways. For example, the simplest design is a single-chamber cesspool. It consists of only one compartment, in which sewage is collected, and needs frequent pumping.

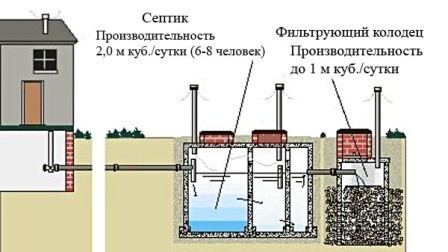

A more advanced version is a cesspool of several compartments. Most often consists of two or three tanks, which are connected with each other by branch pipes.

The first tank receives waste water directly from the house, only the water that has been purified from solid particles pours into the following tanks. After cleaning, the liquid can be drained into the ground - there is no threat to environmentalists it will not carry.

The most modern and perfect septic tanks are multi-chambered closed containers. Inside this container, there are several tanks equipped with special filters, pumps and biological purification systems. Such septic tanks are very effective, as they not only accumulate runoff, but also purify them. Of course, such systems are very expensive, but the water purified in them practically does not contain harmful substances and can be safely used for watering the garden and beds.

Calculation of the discharge pit

This is a very important point, since the construction of a cesspool of concrete rings involves several very important conditions.

First, the cesspool should have such a depth that the level of impurities does not reach the freezing point of the ground. The second condition - groundwater should lie below the base of the cesspool, otherwise there will be a threat of flooding the site with sewage. It is not recommended to dig a pit more than 3.5 m deep, since this is the maximum depth that a standard sewer machine can pull.

Before building a cesspool, it will not hurt to call back to the sewerage service and ask how much the tank can be provided if it is necessary to pump out sewage. Calculate the volume of the pit in such a way that it roughly coincides with the volume of the tank.

For example, you can take an average family of four. Based on the sanitary norms of water consumption per person per day, you can roughly estimate that for a pit of 15 cubic meters you will have to order pumping out at least once a month, provided that people permanently reside in the house. The costs for the services of sewage can be reduced by proceeding as follows: We install two separate tanks. The sewage from the house falls first into one container, begins to ferment there and is gradually divided into solid fractions and water. The liquid in the first container gradually rises and begins to flow through the overflow hole into the second tank.

The overflow hole is located higher than the inlet, so only the purified water enters the second tank. The bottom of the second tank is not made airtight, but is built like a filter, using, for example, a layer of crushed stone and sand. It is necessary to pump out such a system no more than once a year, or even in two years.

Rings for such cesspools, both with a bottom and without it, are produced in iron ore factories and in small private enterprises - they are easy to acquire, and small private enterprises, as a rule, provide delivery themselves.

Pit of concrete rings with your hands

This option, in addition to being reliable and durable, is also considered the cheapest, therefore it is very popular among owners of holiday homes and country houses.

The advantages of concrete rings as a building material for a cesspool are as follows:

- Completely finished elements of the structure fall on the site.

- Installation of concrete rings is very simple and fast.

concrete rings for drainage pit, sizes of concrete rings

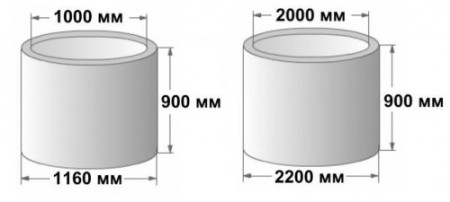

On what parameters to choose concrete rings for the construction of a cesspool? Plants of concrete and small private enterprises offer a wide range of concrete rings, differing in size and design. Their diameter can be from 0.7 to 3 m. The height is 0.9-1 m, but there are additional elements for sale, the use of which allows to obtain a design of the required height. As for the weight of concrete rings, it varies depending on the size of the product. For example, a ring with a diameter of 1 m, a height of 90 cm and a wall thickness of 8 cm weighs about 600 kg, and a diameter of 2 m - about 1500 kg.

Also on sale you can find the rings of the following types:

• With a groove-type lock. The presence of a lock greatly simplifies the installation process, and the finished construction is very stable and airtight.

• Flat circles. The most common product with a flat edge, when they are mounted, metal clips are used, the joints are sealed with a strong cement solution.

• Filtration concrete wheels. They have perforations on the walls, they are used in the manufacture of special filtering tanks in overflow cesspools.

Concrete rings are made using cement grade M500 and above, with each ring necessarily reinforced. If necessary, you can buy rings with a bottom and a lid, thus simplifying the installation process.

choose concrete rings

The final choice should be made only on the basis of a preliminary draft. At the same time, calculations of the discharge pit are necessarily taken into account. In addition, for the correct choice of concrete rings, you need to familiarize yourself with their marking. So, the first two digits in the marking denote the diameter of the ring, the figure after the comma indicates the height.

cesspit materials

To build a full-fledged cesspool of closed type, in addition to concrete circles, a concrete slab-overlap is required, which has a small round hole, through which the sewage will be pumped out. If necessary, you can immediately buy a ready-made slab for the bottom of a sealed cesspool. The plate can be made according to the diameter of the ring.

As for the hatch of the cesspool, it can also be bought in the finished form - plastic or metal. You can make a hatch yourself from concrete or wood.

digging pit for a drain pit

The drainage pit must be located in such a way that:

- Be remote from a residential house at least 5 meters.

- To the next site should be at least 2 meters.

- The source of drinking water (well, well) was at a distance of at least 25 meters from the cesspool.

- There was a free entrance for pumping uncleanness from the cesspool.

After they have decided on the place, they begin to dig a pit. The diameter of the excavation should be greater than the diameter of the ring by about half a meter, since after the installation of the rings it is necessary to make their waterproofing and, if necessary, insulate several upper rings.

Sometimes it is better to dig a square pit - then a concrete slab of the right size can be laid on the bottom, which eliminates the need to do the screed by hand. If you plan to install a ring with a bottom, then the bottom of the finished pit is rammed, a layer of sand is spilled, which is watered. The result is a solid, even surface, suitable for installing a concrete ring.

installation options for concrete rings

Mount the concrete rings in several ways:

If an ordinary ring is installed, it will be necessary to pour the bottom with concrete. To do this, prepare the reinforcement with a section of 10 mm of the required length, lay it on the bottom of the pit in the form of a lattice, fix it with a knitting wire. The reinforcement can not be laid immediately on the bottom of the pit, since it must be in the thickness of the concrete.

For this, stones or pieces of brick are placed under the pins. After that, a mortar of concrete is prepared according to a traditional "recipe": for 1 part of cement 2 parts of sand or granite waste, 3 parts of rubble. Add the water to the consistency of thick sour cream. Use cement grade not less than 400.

It is important to correctly calculate the amount of concrete, since the bottom of the pit must be filled in at a time, without additional mixing. It will greatly accelerate and facilitate the work of the concrete mixer, it can be rented, it is inexpensive. However, if necessary, the concrete can be kneaded and manually.

The concrete mixture is neatly leveled on the bottom of the pit. From concrete it is necessary to remove air bubbles - for this, concrete is rammed with a wooden stick or trimming of the reinforcement.

In order for the concrete to completely freeze, it is necessary to wait about one week. If there is a hot weather, the surface should be periodically watered so that it does not crack.

Using rings with a bottom will save you from laborious work on pouring concrete, you do not need to additionally purchase cement, crushed stone, reinforcement, etc. Of course, experienced builders strongly recommend such an option as more simple and cheaper.

The rings are lowered into the pit in turn, one at a time. As the rings are mounted, the seams should be covered with a strong cement mortar. The solution is also applied to the end of the circle before installing the next ring.

After the installation of the circles is completed, an external waterproofing is produced. To do this, use clay mortar, hot bitumen, etc. The inner side of the circles is often treated with hot bitumen.

whether it is possible to lower the rings manually without a tap

This is quite possible, but one should take into account the considerable weight of concrete products - it is impossible to lower the ring into the hole independently. To do this, you will need at least a good winch and several assistants. For circles with a diameter of 2 m and more, you need a mobile crane, without options.

Each concrete circle is provided with four fastening tabs made of a wire rod with a diameter of 6 mm minimum. For these ears attach a cable. The work on installing concrete rings is not difficult, if the crane operator is experienced. Nevertheless, do not neglect the safety rules:

- Cables are attached to all four ears at the same time.

- The length of the lines should be the same.

- You can not hurry and allow negligence in work.

pipe laying, concreting, ventilation installation

As soon as the installation works are completed, at depths of approximately 8-1 m, holes for the sewer pipe are drilled in the rings and slightly above - for overflowing into the second compartment of the septic tank (if it is planned). After this, you can proceed to install the drain pipes. For this purpose sewage pipes with a diameter of 15 cm are most suitable. They are laid in trenches, observing a slight inclination toward the septic tank, approximately 2-3 cm per 1 m. The entrance of the pipe to the septic tank is not necessary.

After the drain has been checked for operability, the trench can be covered. The earth around the septic tank is spilled so that there is only one hatch on the surface. In the finished floors, as a rule, an opening for ventilation is provided. For a ventilation system, it is best to use a plastic pipe with a diameter of 100 mm.

With properly installed ventilation inside the septic tank, I will not accumulate gases. However, in order to completely eliminate unpleasant odors, you will have to fork out to install a forced ventilation.

Helpful Tips

A few recommendations will help to avoid problems in the process of installing a septic tank.

Thus, in regions with severe winters extreme temperatures can be observed. Therefore, the septic tank will need to be insulated to prevent its freezing. An important point is the availability of a technical hatch to monitor the condition of the septic tank and care for it.

For more effective septic work, special biological preparations can be used. With their help you can better clean the sewage, which eliminates the threat of soil contamination on the site.